I

I

I

I

l

l

l

l

l

l

l

l

l

I

I

l

I

I

I

I

)

I

I

,t

.J

,l

67

FAULT

FINDING

General

Service

hints

lf servicing

has to be carried out the

following

points

should be

taken into account

in

order to avoid

damaging

the instrument.

-

Take care to avoid short'circuits

with measuring clips and hooks

if

the

instrument is

switched-on,

especially

near

the

input

terminals

when high-voltages are

present.

-

Use

miniature

soldering

iron

(35

W max.) with a tin cleaner

or

a

vacuum soldering iron.

-

Use an acid-free solder.

-

When fault-finding, dismantle

the instrument,

unsolder

the battery wires and

loosen the display

board

-

As

the

dismantled

instrument is not very

stable

it is

advised

to use a work

lixing

clamp,

when

measuring

or

replacing

parts.

-

After

repair

the instrument should be calibrated again.

Faull.f inding

procedure

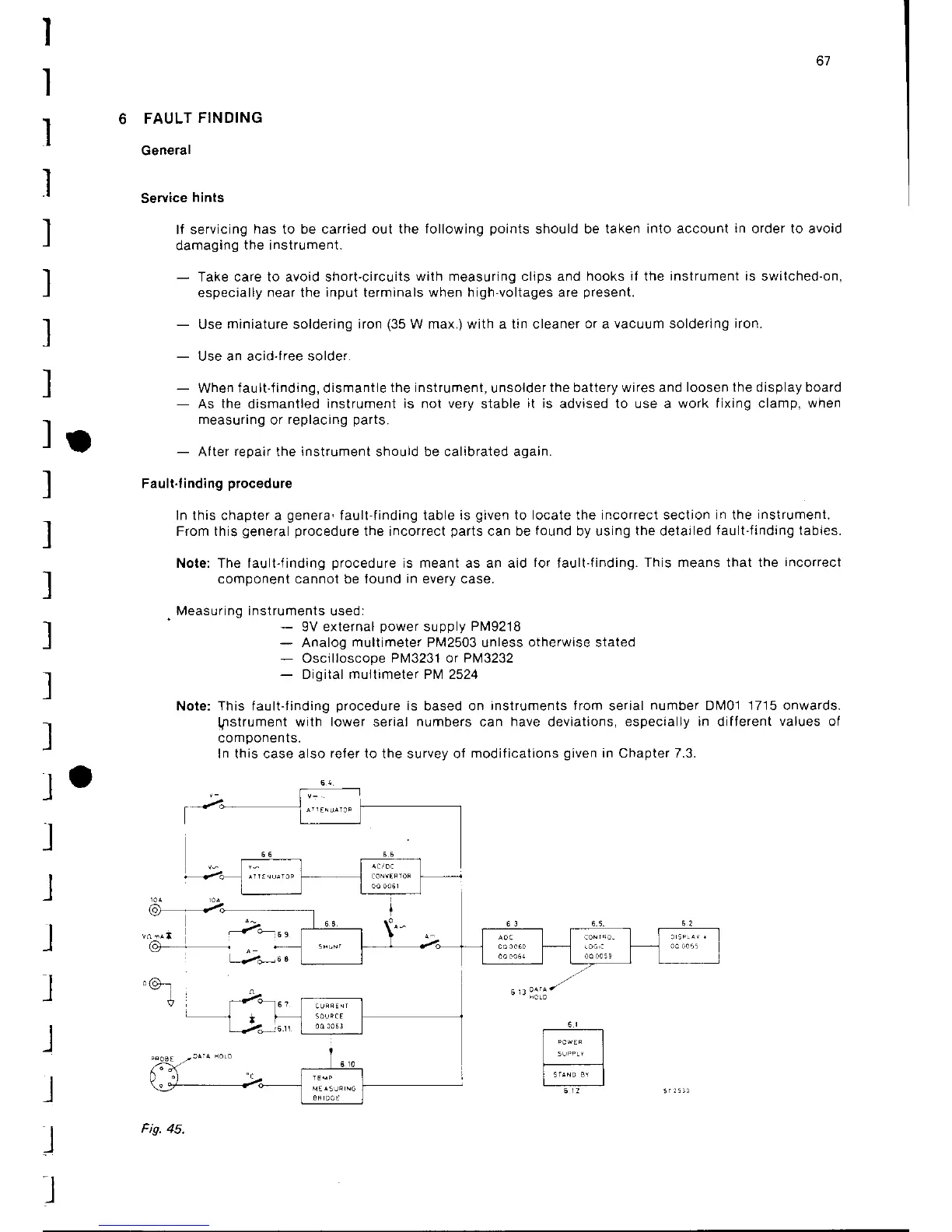

ln this chapter a

genera,

fault-finding table is

given

to locate the incorrect section in the

inslrument.

From this

general procedure

the incorrect

parts

can be

found

by using

the

detailed

fault-finding tables.

Nole: The fault-iinding

procedure

is meant as an aid

for

fault-finding.

This means that the

incorrect

component cannot tle found

in

every case.

.

Measuring instruments

used:

-

9V external

power

supply

P1v19218

-

Analog multimeter PM2503 unless otherwise stated

-

Oscilloscope PN4323'1 or P1v13232

-

Digital multimeter Pl\4 2524

Note: This faultJinding

procedure

is based on

instruments from

serial

number Dl\401 1715 onwards.

l.nstrument

with

lower

serial

numbers

can

have

deviations,

especially in diflerent

values

of

co

m

pone

nt s.

In this case also

refer

to the survey of

modifications

given

in Chapter 7.3.

2*'""

6,3:älä

t-19,45.

Loading...

Loading...