HEADLIGHTS AIMING CHECK - APE TM P703

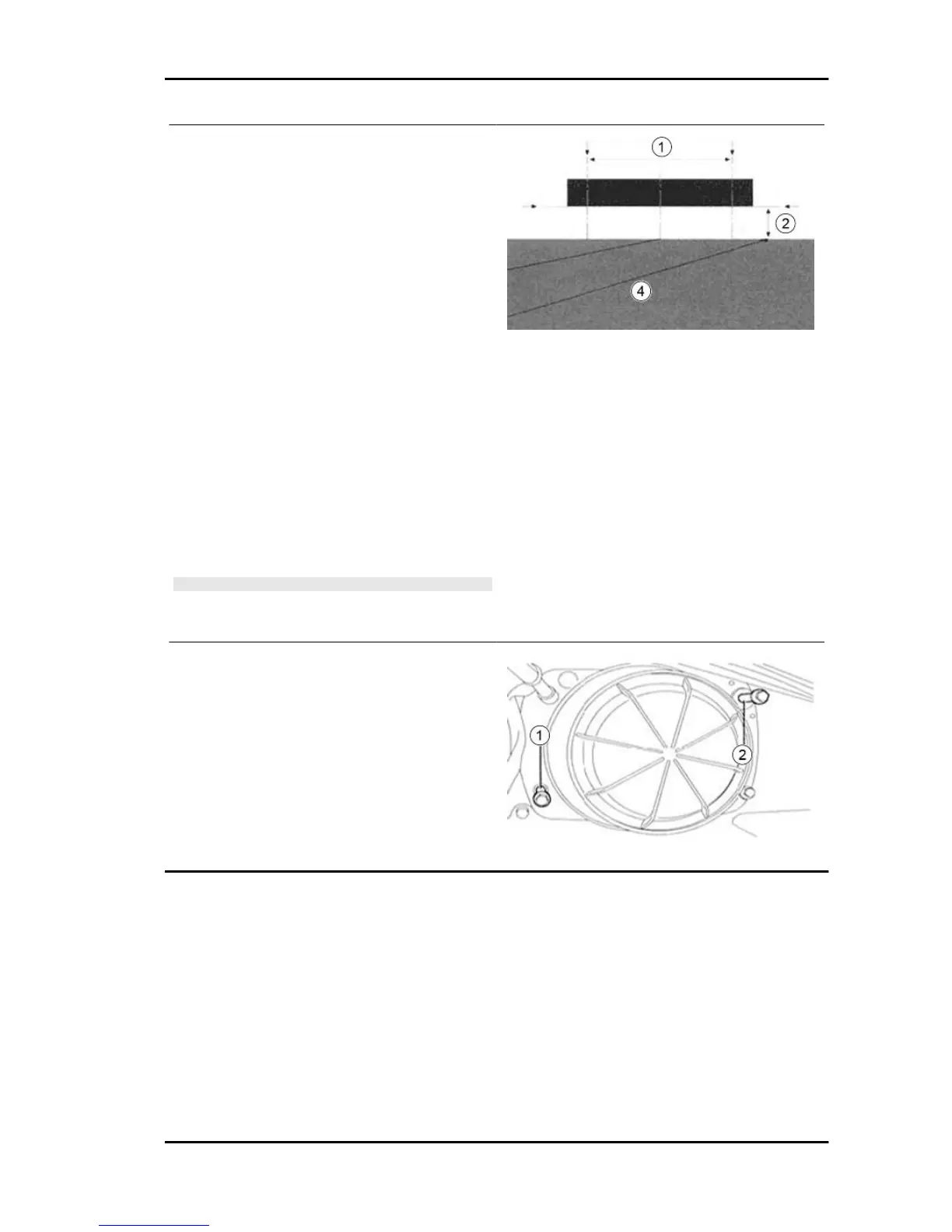

FL2

Position the unloaded vehicle on a flat surface and

at 10 m (4) away from a white screen located in

the dark (see the figure) and make sure that the

vehicle axis is perpendicular to the screen. Draw

two vertical lines "↓-↓", on the screen, at a distance

"(1)" corresponding to the distance between head-

light axes. Draw a horizontal line "→ - ←" whose

height "(2)" from the ground corresponds to 0.9 x

(3); with the low-beam headlight on, the horizontal

borderline between the dark and the light zones

should not be above the horizontal line "→-←".

Now switch on the high-beam lights and check that

the centre of the depth light beam for each head-

light is on the corresponding vertical line "↓-↓", or

slightly outside that line.

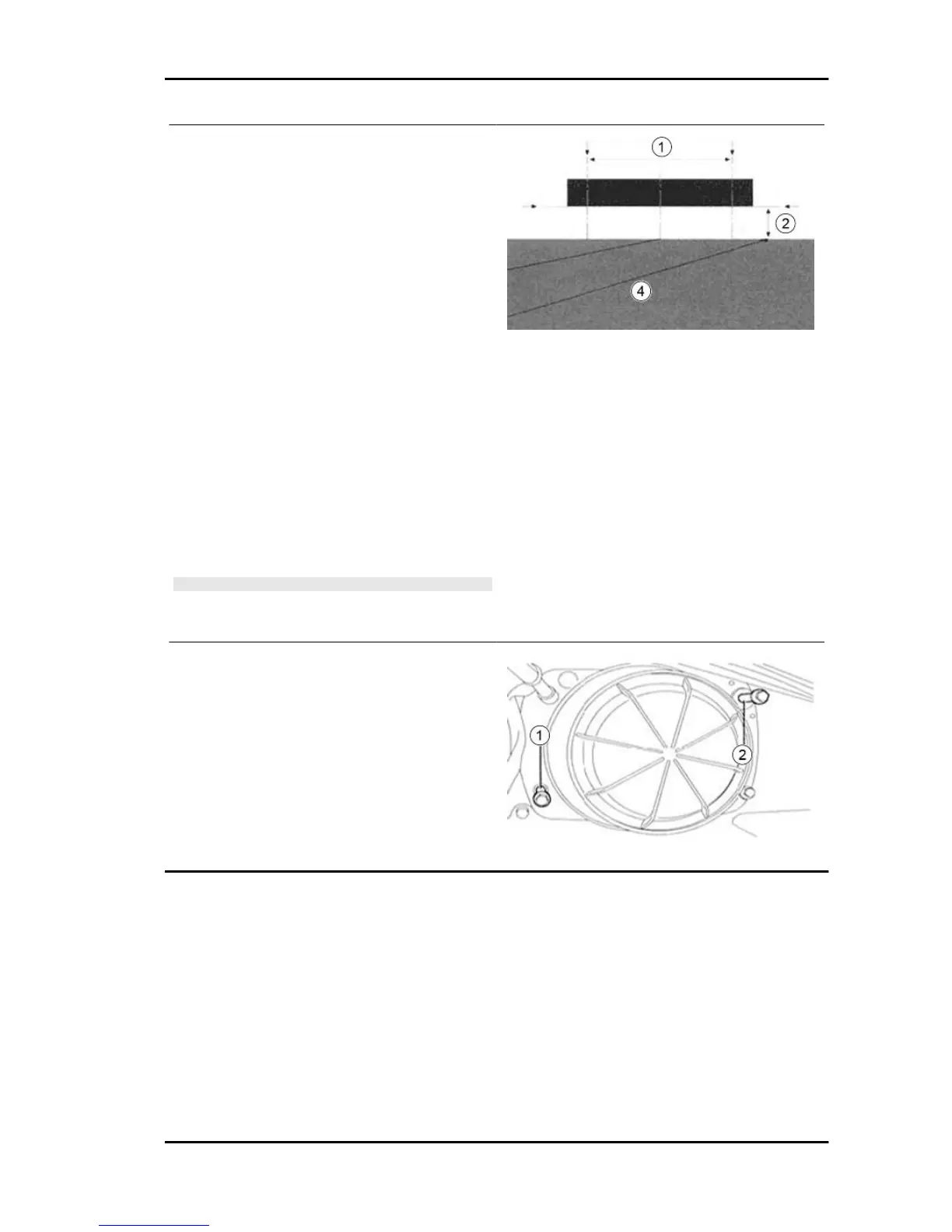

N.B.

BEFORE CARRYING OUT THIS CONTROL, MAKE SURE

THAT THE FRONT AND REAR TYRES ARE INFLATED TO

THE PRESSURES SPECIFIED IN THE CHARACTERISTICS.

Both headlights have 2 adjustment screws, "(1)"

and "(2)", located at the back of the headlight used

to correct any misalignment of the light beam:

screw "(1)" to adjust divergence; screw "(2)" to ad-

just angle.

APE TM Benzina Maintenance

MA - 39

Loading...

Loading...