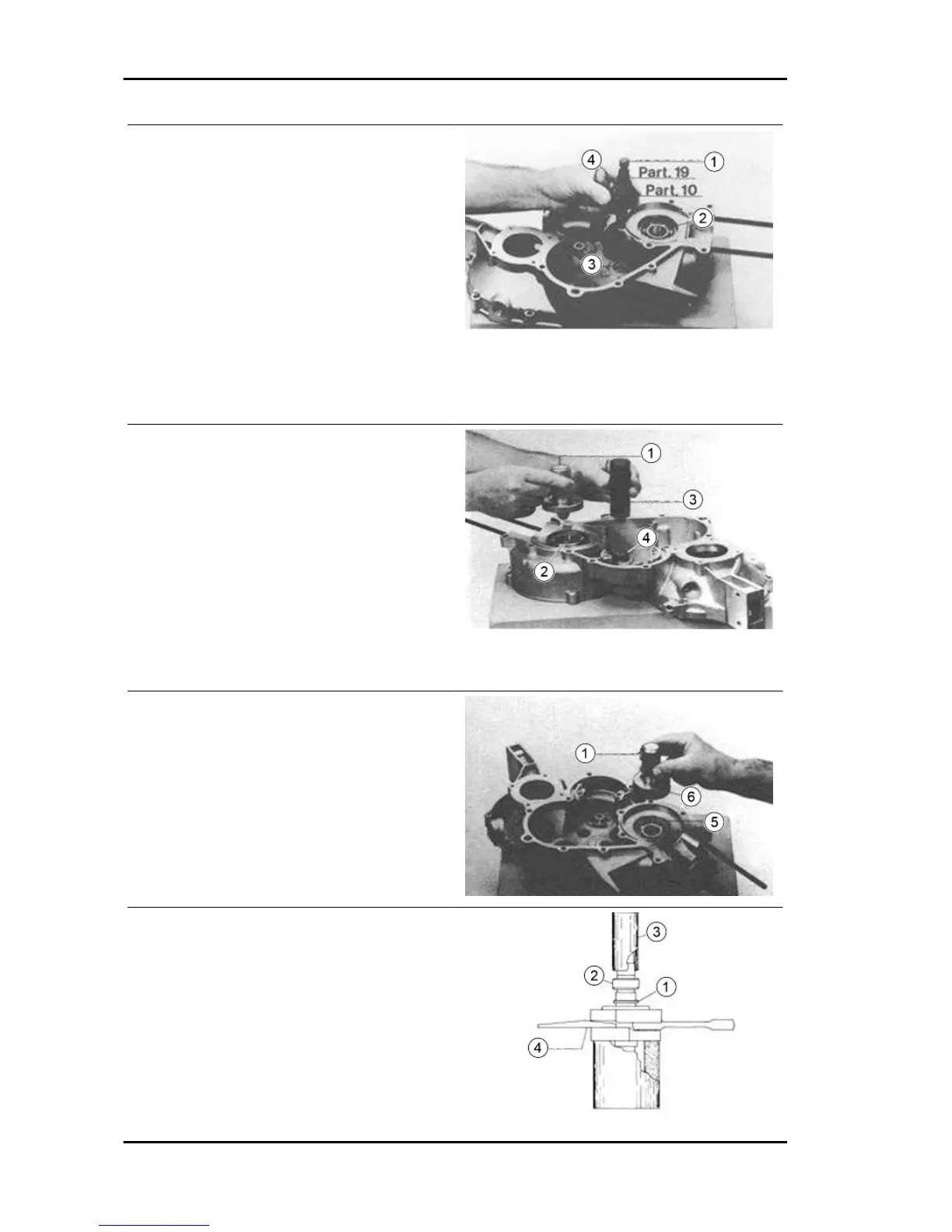

MULTI-GEAR PIN ROLLER BEARING

Use the special tool (1) provided in items 10 and

19, and pull the roller bearing (3), acting on the

central nut (4).

Specific tooling

T.0021467 Bearing extractor

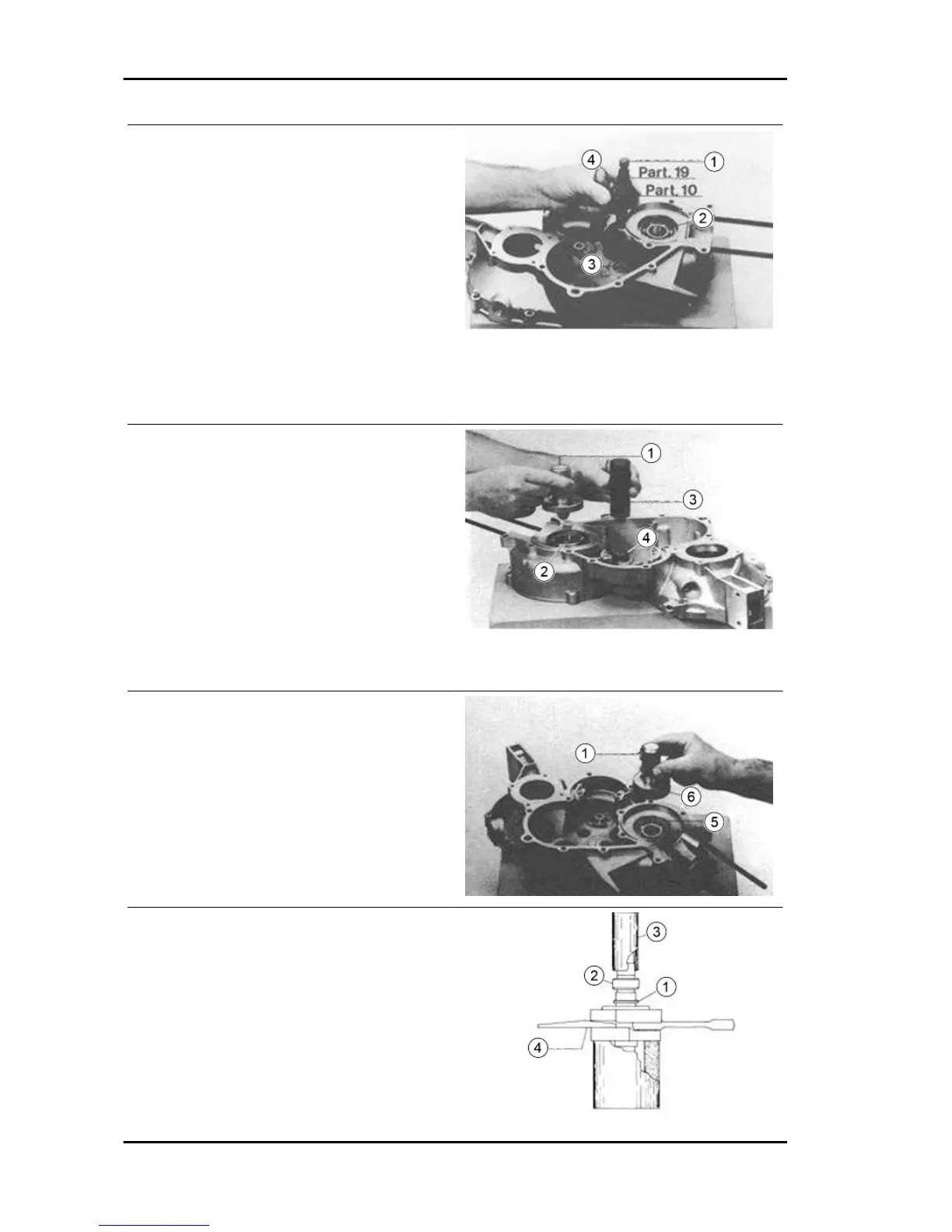

CLUTCH-SIDE CRANKCASE HALF - FITTING

Similarly to the procedure for installing the flywheel side crankcase, heat the special tool, the area

housing the bench ball bearing.

BENCH BALL BEARING - MULTI-GEAR ROLL-

ER BEARING

Insert, using the special tool (1), the bench ball

bearing (2) in its housing, wait until the crankcase

has cooled, and fit, with the appropriate tool, the

roller bearing (4) of the multi-gear pin.

Specific tooling

T.0023589 Punch for bearings and sealing

rings

T.0033970 Punch for fitting roller bearings

CIRCLIP - SEAL RING

Assemble, with the help of specific pliers, the cir-

clip (1) and, redeploying the specific tool (2), the

seal ring (3).

Specific tooling

T.0022465 Pliers for circlips

T.0023589 Punch for bearings and sealing

rings

SPACER - BENCH ROLLER BEARING INTER-

NAL RING

Insert the clutch side crankshaft on a support base

with internal Ø of 36 mm. and, after mounting the

spacer (1), mount the inner ring (2), heated in an

oil bath at 100°C, of the bench roller bearing on the

crankshaft (flywheel side) using as a punch (3) a

section of pipe with internal diameter of 29 mm.

Engine APE TM Benzina

EN - 80

Loading...

Loading...