Component Maintenance Manual

EFFECTIVITY: ALL

21-00-35

Page 5001

JUNE 15, 2011

CHECK (INSPECTION SCHEDULE)

TASK 21-00-22-21-801

7.0 R12 AIR CONDITIOING SYSTEM COMPONENT – INSPECTION SCHE

DULE

SUBTASK 21-00-22-21-001

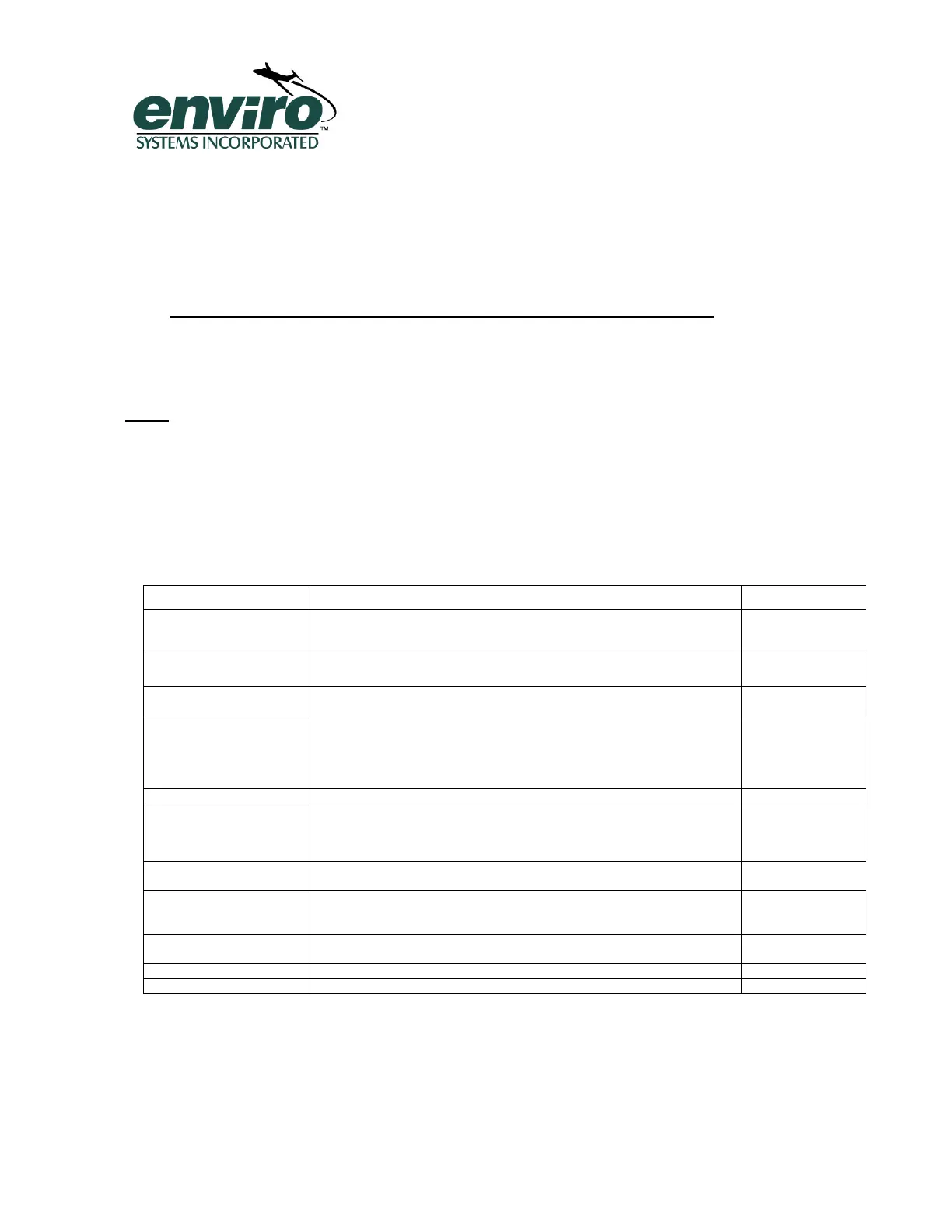

7.1 Compressor Condenser Module Inspection Schedule:

NOTE

: This is the recommended visual inspection schedule for the Compressor Condenser Module

Assembly. Adherence to this schedule will ensure that all components of the assembly are in accordance

with the manufacturer’s specifications and is necessary to detect structural failure, deterioration or damage,

and to determine the need for corrective action.

7.1.1 If any component listed in this schedule requires cleaning, refer to Cleaning Procedure

(Section 6).

7.1.2 If any component listed in this schedule requires repair and/or replacement, refer to Repair

(Section 8).

Component Type Inspection Service Hours

Drive belt/pulley/ cover Visually inspect for wear, nicks, cracks or looseness, and proper tracking.

Realign & tension and/or replace as required.

Inspect belt cover for cracks or other damage.

500

Compressor shaft seal Visually inspect for leaks (excessive oil spray)

500

Condenser outlet and fan

shrouds

Visually inspect condenser outlet and fan shroud for signs of cracking,

separation between shroud and condenser coil.

500

Condenser coil Visually inspect condenser coil for damage or dirt accumulation.

Visually inspect, clean and comb coil fins.

Inspect for leakage.

Inspect plumbing for damage weathering and wear

Visually inspect return bends for nicks, dents, cracks, or other damage..

500

Electrical wiring Visually inspect wiring for insulation damage, replace as required. 500

Drive motor Visually inspect drive motor commutator for wear

Internal contamination inspection

Motor bearing inspection (refer to Special Procedures, Section 12)

500

500

Drive Motor Brushes Replace Brushes Mandatory every

500 hours

Receiver dryer assembly Inspect for leakage.

Inspect plumbing for damage, weathering, and wear.

Verify mounting hardware is secure.

500

Motor insulation resistance

check

Refer to Special Procedures, Section 12.3 500

Hour Meter Inspect for proper operation and damage. 500

Table 3.5 Compressor Condenser Module Inspection Schedule

Loading...

Loading...