YELLOW SafeSense ALERT: If light comes on during

normal operation, check and clean the engine air

filter. Check the carburetor air filter for holes, tears,

or punctures and replace if damaged. If the light still

remains on, the machine must be serviced by a

qualified technician.

NOTE: Any light that is on when the engine stops will

remain illuminated for 20 seconds to indicate the reason

for machine shut down.

The oxygen sensor must reach operating temperature

before it will start to send signals to the SafeSense

module. This warm up period is approximately 3 minutes.

After the initial 3 minutes, the module will start evaluating

the signal from the oxygen sensor and if the module

receives an abnormal reading for a period of 1 minute, the

unit will shut down. If the machine is also allowed to idle

for more than 4 minutes, an indicator light will flash for 1

minute and then the engine will shut down. If this

happens, turn the key to the “off” position several seconds

to clear the SafeSense module and restart the engine.

Once the engine has started, advance the bail throttle to

operating position and start the operation. With the engine

at full throttle, under load, the signal from the oxygen

sensor should be within the normal operating ranges for

safe operation. If the engine’s air intake filter needs to be

serviced, or an over-filled cylinder has been installed by

mistake, or there is a problem with the fuel system that

causes the oxygen sensors signal to be out of range,

SafeSense will shut the unit down after 1 minute. The unit

can be re-started after clearing the module by turning off

the key switch. If corrections have not been made to the

unit, SafeSense will continue to shut the unit down until

the problem is corrected.

Engines tend to go to a lean burn if allowed to idle for

even short periods. Even at high idle speeds most

engines will continue to lean downward. It is always best

to shut the engine off when it is not being used to do work.

Remember, the engine is always creating emissions as

long as it is running.

The best manner to operate a unit equipped with

SafeSense is as follows.

1. With the bail throttle in the idle position, turn the key

switch to the start position, once the engine starts,

advance the bail throttle to the operating position.

2. When ready to stop operation, release the bail throttle.

If the unit will not be used within forty-five seconds,

turn the key switch to the off position. If the unit will

not be returned to service within a few minutes it is

best to turn the gas valve on the tank off first and let

the engine consume all fuel that is in lines. Once the

engine dies, turn the key switch to off position.

3. When ready to restart, open the gas valve on the tank,

and turn key switch to the start position. Once the

engine has started, move bail throttle to the operating

position and return to operation.

Hour Meter / Tachometer

The hour meter / tachometer records the number of hours

the machine has been powered ON. The hour meter

reading is used to mark recommended maintenance

intervals. It also displays the engine speed. This meter

displays hours when the machine is turned OFF and

engine speed when the machine is turned ON.

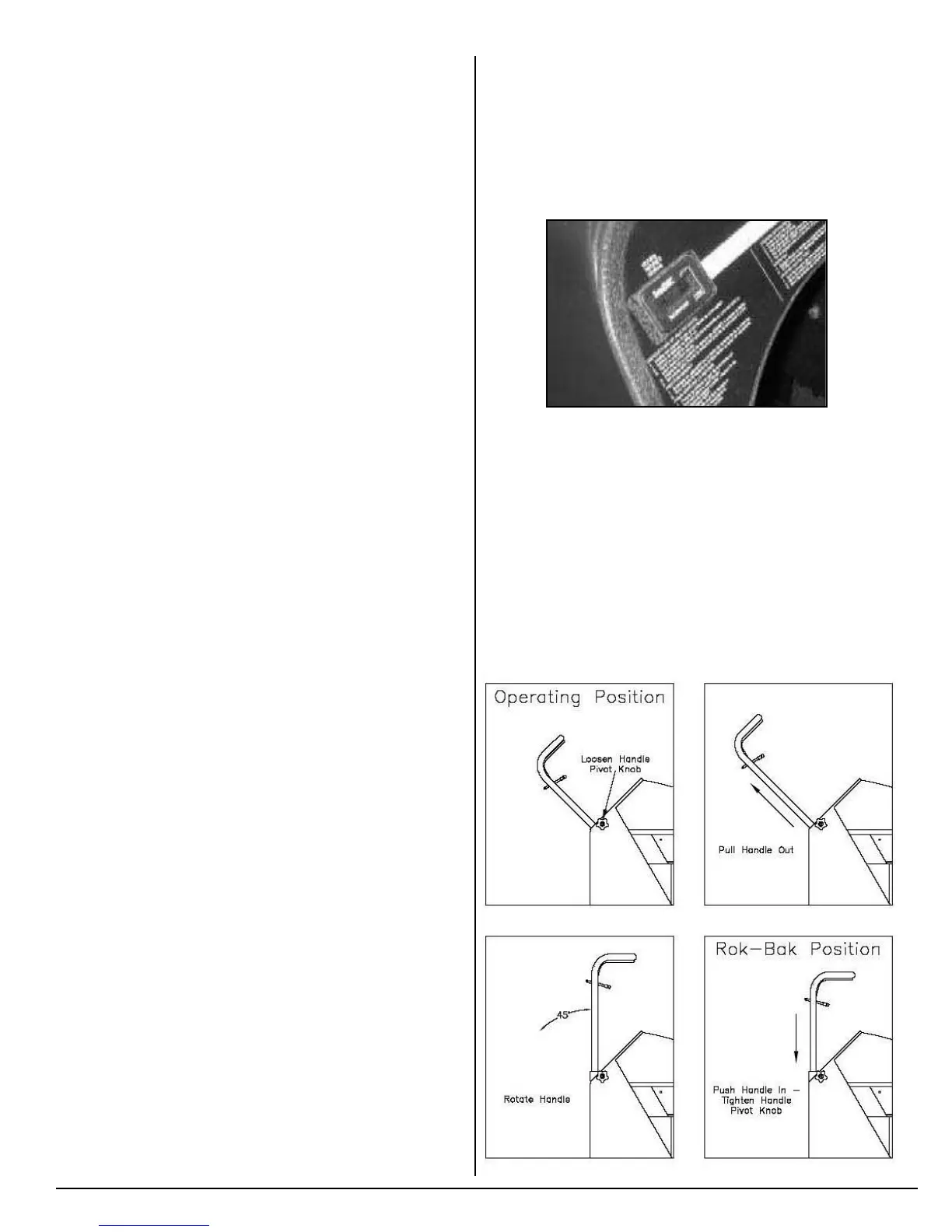

Rok-Bak

1. Close the valve on the propane cylinder, allow the

engine to stop and turn the machine OFF.

2. Remove the propane cylinder.

3. Loosen the handle pivot knobs so that the handle

can slide.

4. Pull the handle out until it stops.

5. Rotate handle towards the front of the machine

until it is vertical.

6. Push downward on the handle until it stops.

9

Loading...

Loading...