Transport Cart

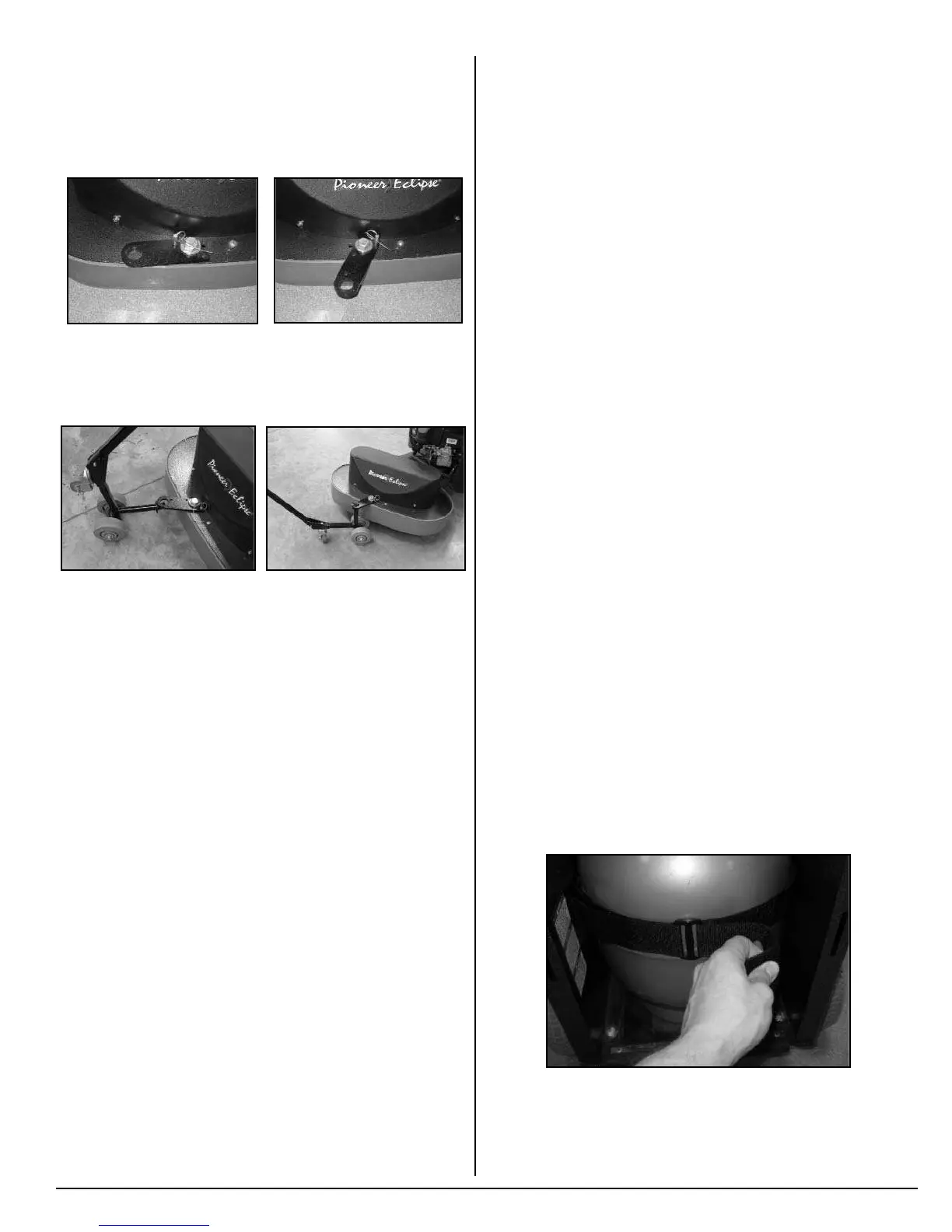

1. Locate the transport arm located on the front of

the deck. Remove the pull pin and rotate the arm

to an outward position. Reinsert the pull pin to

lock the arm in the outward position.

2. Place the hook of the transport cart inside the hole

of the transport arm. In one smooth motion, pull

the handle up and over rotating the transport cart

on the two main wheels.

3. With the brushes off the floor the machine is ready

to move.

4. To remove the transport cart, place the cart and

the machine in a straight line.

5. Use the handle of the transport cart and pull the

handle up and over towards the machine. The

cart will rotate on the two main wheels and

disconnect from the transport arm.

How the Machine Works

This machine is a propane stripper that has a gearbox

assembly that is belt driven directly from the engine crank

shaft.

Pre-Operation Checklist

Check the engine oil level. Add oil if needed.

Refer to Maintenance.

Inspect the engine dust filter and clean off any

debris or dust buildup. Refer to Maintenance.

Inspect the brushes and replace, if necessary.

Refer to Maintenance.

Inspect the brushes for cracks or damage!

Replace if necessary. Refer to Maintenance.

WARNING! A DAMAGED BRUSH/PAD HOLDER

ROTATING AT HIGH SPEEDS MAY BE AN EXTREME

HAZARD IF IT SHOULD DISINTEGRATE.

Inspect air filter. Clean or replace if necessary. A

dirty air filter could lead to elevated levels of

carbon monoxide. Refer to Maintenance.

Inspect the drive belt. Replace if necessary.

Refer to Maintenance.

Check the machine for leaks or loose fasteners.

LP Fuel Cylinder

This machine uses the 20 lb (9.1 kg) capacity cylinder,

which meets the D.O.T. 4E240 standards. These cylinders

are also listed by UL. In addition, the steel cylinder meets

European TPED specifications and is CE compliant.

Filling should be done ONLY by a qualified propane dealer.

A properly filled cylinder should not exceed 80% of the

rated capacity. Do not overfill the cylinder or use a liquid

withdraw cylinder on the machine. The use of a liquid

withdraw cylinder on a vapor withdraw system could freeze

the regulator and create a fire hazard.

Installing the LP Cylinder

1. Before bringing a propane cylinder indoors, always

check it for over-filling.

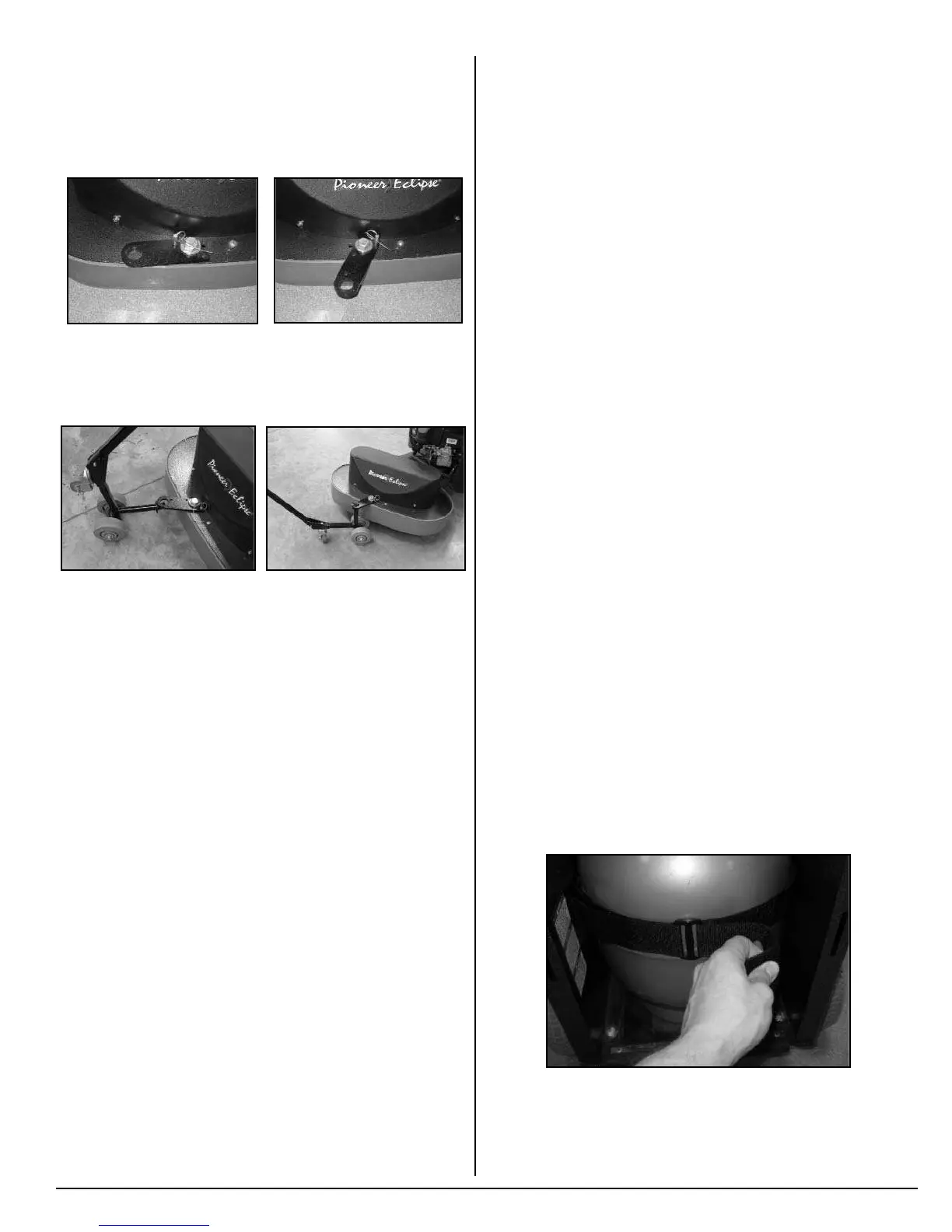

2. Place the tank on the machine and secure with the

retaining strap. Remove slack by pulling on the

loose end of the strap and secure back to strap.

Connect the fuel hose coupling to the service

valve by turning clockwise. HAND TIGHTEN

ONLY. Make sure coupling is not cross threaded

and check for leakage by noting any propane

odors immediately after cylinder is connected. (It

is sometimes easier to install if the connection to

the service valve is made before strapping the

cylinder in place.)

11

Loading...

Loading...