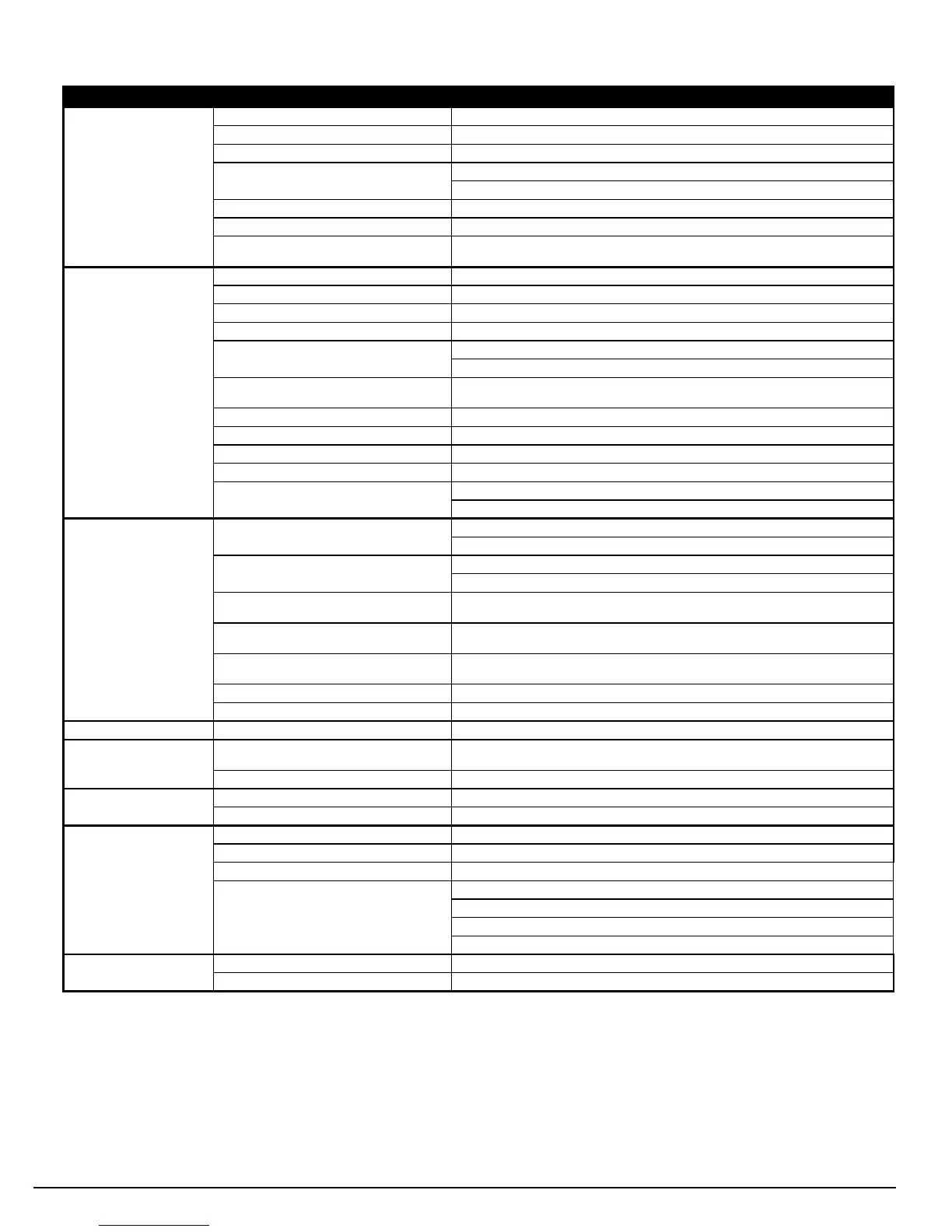

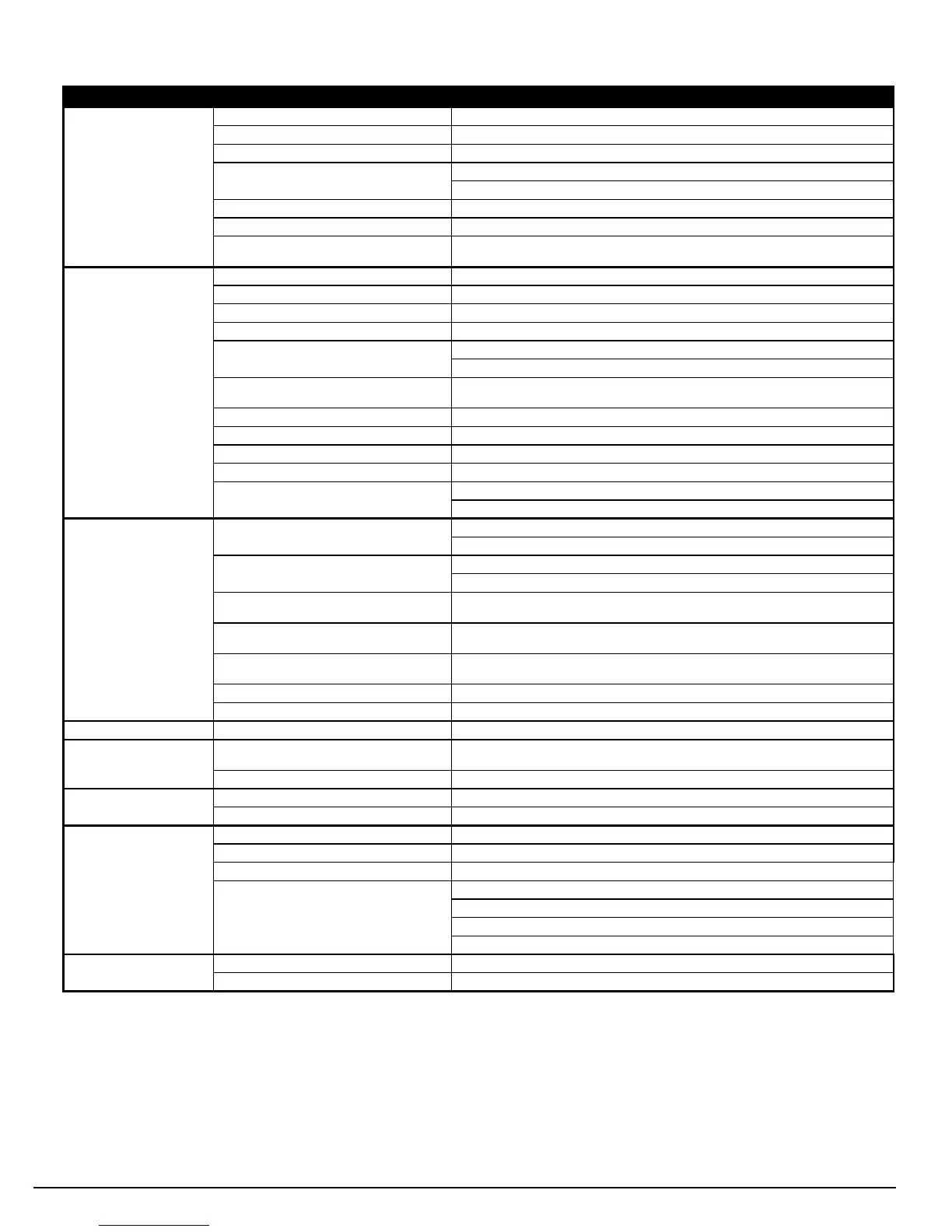

Machine Troubleshooting

14

Problem Possible Cause Solution

Propane cylinder is not properly connected. Check connection and open service valve slowly.

Battery is weak. Charge battery or replace.

Oil level is to low. Check the oil level and add if needed.

Place the engine throttle in the idle "slow" position.

Check the regulator vacuum hose for breaks, pinched hose, or a bad connection.

Coil air gap out of adjustment. Adjust coil air gap (Check FS481V Service Manual). Contact an APEC Certified Technician.

Spark plug or head bolts loose. Retorque (Check FS481V Service Manual). Contact an APEC Certified Technician.

Head gasket blown or valves need adjusting

Replace head gasket, adjust valves and replace if necessary (Check FS481V Service

Manual). Contact an APEC Certified Technician.

Propane cylinder is empty. Install properly filled cylinder.

Oil level is to low. Check the oil level and add if needed.

Machine is in the Rok-Bak position. Lower the machine to operating position.

Main fuse is blown. Inspect fuse and if blown replace

Place the engine throttle in the idle "slow" position.

Check the regulator vacuum hose for breaks, pinched hose, or a bad connection.

Head gasket blown or valves need adjusting

Replace head gasket, adjust valves and replace if necessary (Check FS481V Service

Manual). Contact an APEC Certified Technician.

Wires broken or disconnected. Reconnect or replace wires. Contact an APEC Certified Technician.

Coil(s) defective. Replace coil(s) (Check FS481V Service Manual). Contact an APEC Certified Technician.

Spark plug gap is incorrect. Adjust gap to 0.025" (.64mm)

Spark plug defective. Replace spark plug.

If the light is on, turn the key switch off and wait 30 seconds. Try again.

Bad module. Contact an APEC Certified Technician.

Place the engine throttle in the idle "slow" position.

Check the regulator vacuum hose for breaks, pinched hose, or a bad connection.

Clean or replace the primary filter (paper element).

Clean or replace the secondary filter (foam element).

Governor out of adjustment or malfunctioning.

Adjust governor and replace if necessary (Check FS481V Service Manual). Contact an APEC

Certified Technician.

Replace head gasket (Check FS481V Service Manual). Contact an APEC Certified

Technician.

Worn piston ring(s) and/or cylinder head(s) require replacement (Check FS481V Service

Manual). Contact an APEC Certified Technician.

Fuel mixture is to lean. Check and adjust fuel mixture if necessary. Contact an APEC Certified Technician.

Valves need adjusting or replacing. Adjust valves (Check FS481V Service Manual). Contact an APEC Certified Technician.

Belt out of adjustment. Check the automatic tensioner

Check the engine, tensioner, spindle, and pad holder fasteners. Tighten any fasteners that

may be loose.

Brushes not installed correctly. Remove brushes and install properly. Check for cracks or tears. Replace if necessary.

Low air pressure in tire(s). Check air pressure in both tires and add if necessary.

Wheel bearing is bad. Replace wheel.

Propane cylinder is empty. Install properly filled cylinder.

Engine oil level is to low. Check the oil level and add if needed.

Dirty air filter. Clean both filters or replace if necessary.

Check close loop vacuum line.

Clean all filters and replace if necessary.

Check for any loose wiring or fuel line connections.

Service machine and check the fuel settings. Contact an APEC Certified Technician

Loose Connection Check all of the wiring for a bad connection or broken wire

Clutch is bad Replace clutch if necessary. Contact an APEC Certified Technician

SafeSense shut the machine down

Machine pulls to one side

SafeSense shut the machine down

Loading...

Loading...