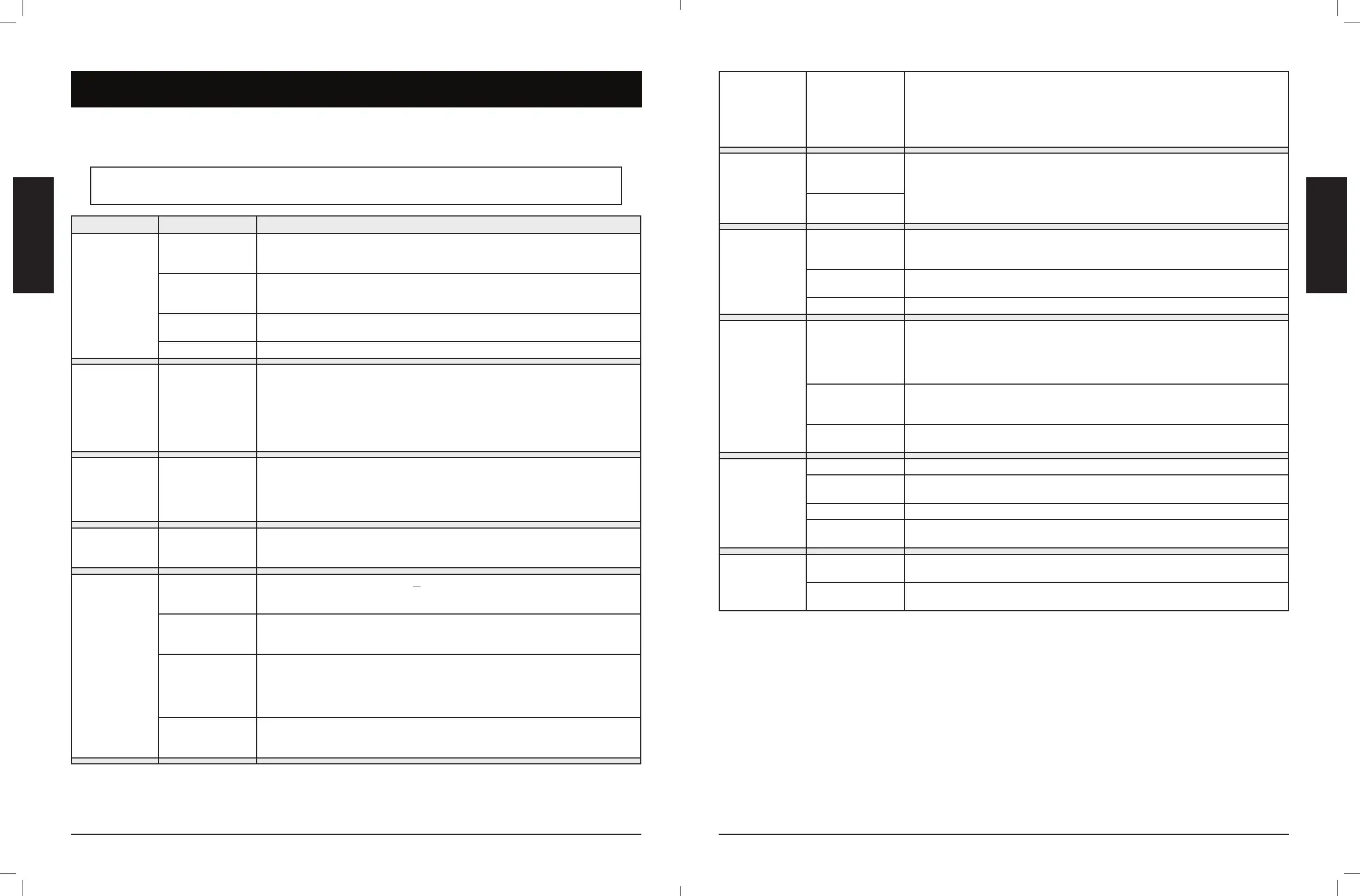

2120

"Er3" Error Code Fre hs one out Chec hopper for suffcent fuel or f there s n obstructon n the feed sstem Remove pellets

nd follow

Care and Maintenance

nstructons Chec Grll Probe Follow

Care and Maintenance

nstructons f drt Chec Burn Pot for sh buld-up or obstructons Follow

Care and Maintenance

nstructons for sh buld-up Chec fn Ensure t s worn properl nd r nte s not bloced

Follow

Care and Maintenance

nstructons f drt Chec uer motor to confrm operton, nd

ensure there s no bloce n the uer tube

"ErP" Error Code Unit Not Turned Off

Properly When Last

Connected To Power.

Safety feature prevents an automatic restart. Turn the Temperature Control Dial to the OFF position to

turn the unit off, wait two minutes, then turn the Temperature Control Dial to the SMOKE position to

turn the unit on again. If error code still displayed, contact Customer Care.

Power Outage While

Unit In Operation.

"noP" Error Code Bad Connection At

Connection Port

Disconnect meat probe from connection port on the Control Board, and reconnect. Ensure the meat

probe adapter is firmly connected. Check for signs of damage to the adapter end. If still failed, call

Customer Care for replacement part.

Meat Probe Damaged Check for signs of damage to the wires of the meat probe. If damaged, call Customer Care for

replacement part.

Faulty Control Board Control Board needs to be replaced. Contact Customer Care for a replacement part.

Grill Will Not Achieve

Or Maintain Stable

Temperature

Insufficient Air Flow

Through Burn Pot

Check Burn Pot for ash build-up or obstructions. Follow

Care and Maintenance

instructions for

ash build-up. Check fan. Ensure it is working properly and air intake is not blocked. Follow

Care and

Maintenance

instructions if dirty. Check auger motor to confirm operation, and ensure there is no

blockage in the auger tube. Once all the above steps have been done, start the grill, set temperature

to and wait for 10 minutes. Check that the flame produced is bright and vibrant.

Lack Of Fuel, Poor Fuel

Quality, Obstruction In

Feed System

Check hopper to check that fuel level is sufficient, and replenish if low. Should the quality of wood

pellets be poor, or the length of the pellets too long, this may cause an obstruction in the feed system.

Remove pellets and follow

Care and Maintenance

instructions.

Grill Probe Check status of Grill Probe. Follow

Care and Maintenance

instructions if dirty. Contact Customer Care

for a replacement part if damaged.

Grill Produces Excess

Or Discolored

Smoke

Grease Build-Up Follow

Care and Maintenance

instructions.

Wood Pellet Quality Remove moist wood pellets from hopper. Follow

Care and Maintenance

instructions to clean out.

Replace with dry wood pellets.

Burn Pot Is Blocked Clear Burn Pot for ash and other debris. Follow Hopper Priming Procedure.

Insufficient Air Intake

For Fan

Check fan. Ensure it is working properly and air intake is not blocked. Follow Care and Maintenance

instructions if dirty.

Frequent Flare-Ups Cooking Temperature Attempt cooking at a lower temperature. Grease does have a flash point. Keep the temperature under

176°C / 350°F when cooking highly greasy food.

Grease Build-Up On

Cooking Components

Follow

Care and Maintenance

instructions.

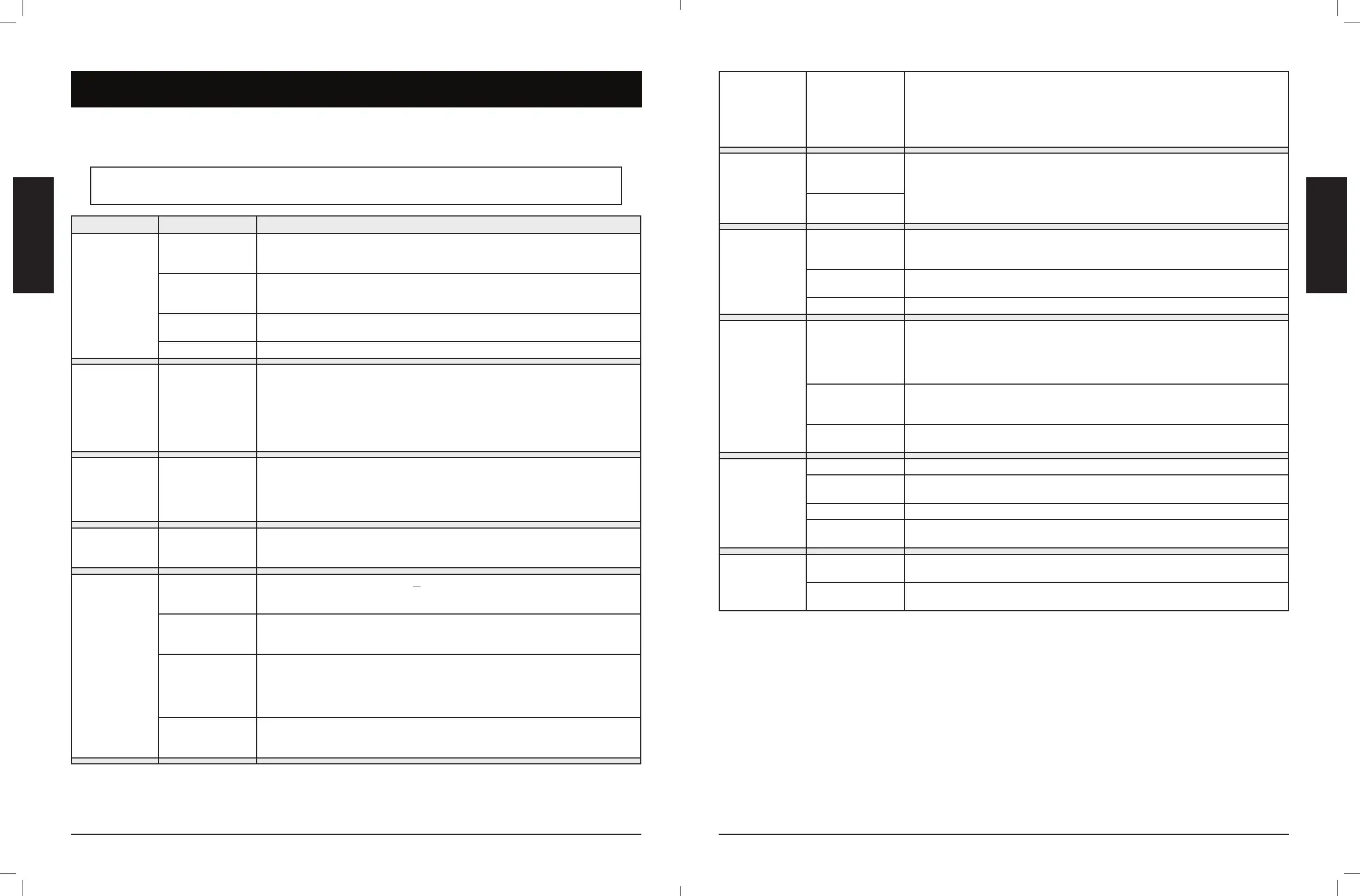

Proper cleaning, maintenance and the use of clean, dry, quality fuel will prevent common operational problems. When your Pit

Boss® grill is operating poorly, or on a less frequent basis, the following troubleshooting tips may be helpful. For FAQ, please visit

www.pitboss-grills.com

. You may also contact your local Pit Boss® authorized dealer or contact Customer Care for assistance.

WARNING: Always disconnect the electrical cord prior to opening the grill for any inspection, cleaning,

maintenance or service work. Ensure the grill is completely cooled to avoid injury.

PROBLEM CAUSE SOLUTION

No Lights On The

Control Board

Not Connected To Power

Source

Ensure unit is plugged into a working power source. Reset breaker. Ensure GFCI is a minimum 10 Amp

service (see

Electric Wire Diagram

for access to electric components) Ensure all wire connections are

firmly connected and dry.

Fuse Blown On The

Control Board

Remove hopper access panel (see

Electric Wire Diagram

for diagram), press in plastic tabs holding the

control board in place and carefully pull controller inside the hopper to release controller. Check the fuse

for a broken wire or if the wire has turned black. If yes, fuse needs to be manually replaced.

The GFCI Outlet Hs

Been Trpped

Ensure GFCI s mnmum 10 Amp servce

Faulty Control Board Control Board needs to be replaced. Contact Customer Care for a replacement part.

Flashing Temperature

On LCD Screen

Grill Temperature Is

Below 65°C /150°F

This is not an error that effects the unit; however, it is used to show that there is some risk that the

fire could go out. Check hopper for sufficient fuel or if there is an obstruction in the feed system.

Remove pellets and follow

Care and Maintenance

instructions. Check Grill Probe and follow

Care and

Maintenance

instructions if dirty. Check Burn Pot for ash build-up or obstructions, and follow

Care and

Maintenance

instructions for ash build-up. Check fan. Ensure it is working properly and air intake is not

blocked. Follow

Care and Maintenance

instructions if dirty. Check auger motor to confirm operation

(rotation), and ensure there is no blockage in the auger tube.

"ErH" Error Code The Unit Has

Overheated, Possibly

Due To Grease Fire Or

Excess Fuel.

Turn the Temperature Control Dial to the OFF position to turn the unit off and allow grill to cool.

Follow

Care and Maintenance

instructions. After maintenance, remove pellets, and confirm

positioning of all component parts. Once cooled, turn the Temperature Control Dial to the SMOKE

position to turn the unit on, then select desired temperature. If error code still displayed, contact

Customer Care.

"Er1" Error Code Grill Probe wire not

making connection.

Remove hopper access panel (see

Electric Wire Diagram

for diagram), and check for any damage

to the Grill Probe wires. Ensure Grill Probe molex connectors are firmly connected, and connected

correctly, to the Control Board.

"Er2" Error Code Auger Not Primed Before the unit is used for the first time or anytime the hopper is completely emptied out, the auger

must be primed to allow pellets to fill the auger tube. If not primed, the igniter will timeout before the

pellets reach the Burn Pot. Follow

Hopper Priming Procedure

.

Auger Motor Is Jammed Remove cooking components from the main barrel. Turn the Temperature Control Dial to the SMOKE

position to turn the unit on and inspect the auger feed system. Visually confirm that the auger is

dropping pellets into the Burn Pot. If not operating properly, call Customer Care for assistance.

Igniter Failure Remove cooking components from the main barrel. Turn the Temperature Control Dial to the SMOKE

position to turn the unit on, and inspect the igniter. Visually confirm that the igniter is working by

placing your hand above the Burn Pot and feeling for heat. Visually confirm that the igniter is protruding

approximately 13mm / 0.5 inches in the Burn Pot. If not operating properly, follow

Manual Start-up

Procedure

to continue use of grill; however, call Customer Care for assistance or a replacement part.

Insufficient Air Flow

Through Burn Pot

Check Burn Pot for ash build-up or obstructions. Follow Care and Maintenance instructions for ash build-

up. Check fan. Ensure it is working properly and air intake is not blocked. Follow

Care and Maintenance

instructions if dirty.

Loading...

Loading...