13

8.7 Operation in the standard mode

ecoMAX810 TOUCH P-L boiler regulator is

equipped with boiler output modulation

function enabling gradual reduction of boiler

output when approaching the preset boiler

temperature. In this mode of regulation, the

regulator uses output modulation algorithm.

Levels of boiler output are available in menu:

BOILER SETTINGS > Output Modulation

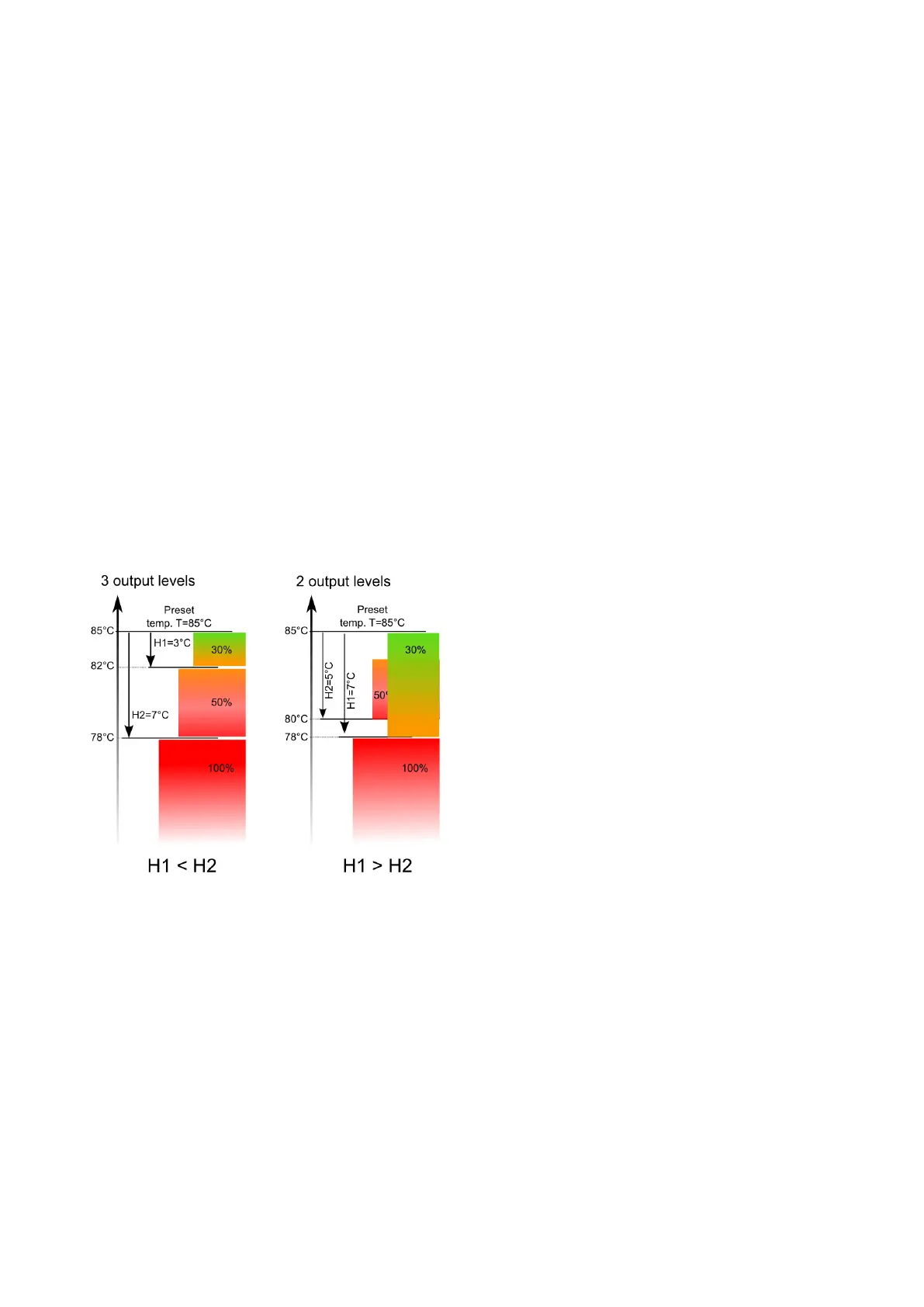

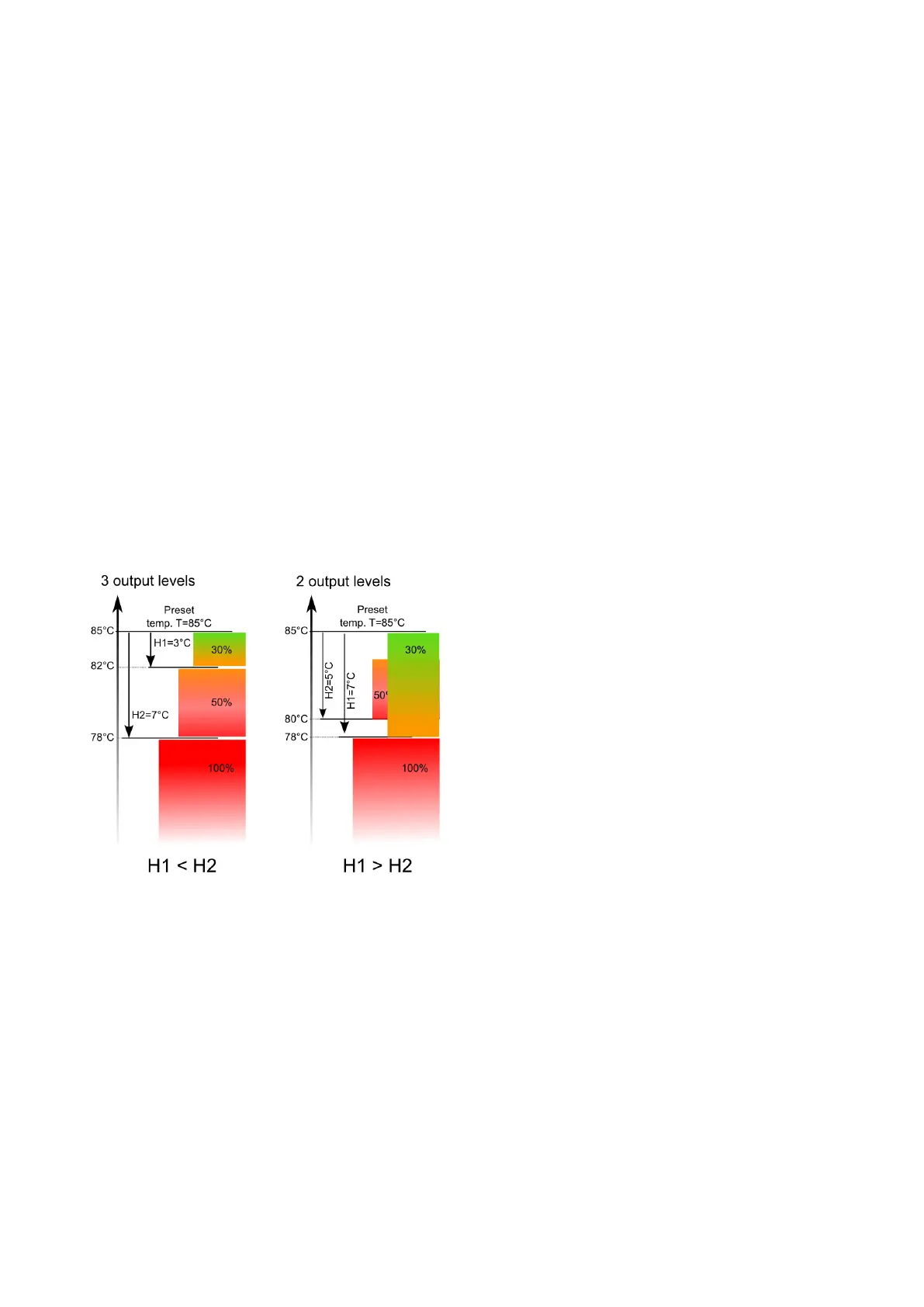

Each of the levels (100%, 50% or 30%) may

be assigned individual values of fuel feeding

time and blow-in output, which determine

actual boiler output. Values of hysteresis (H1

and H2) determine when the boiler should

work with selected output level. Each of

these values is referred to the measured

boiler temperature vs. its preset value. H1

and H2 values may be so set-up that the

modulation will follow without intermediate

level i.e. the boiler output will change

directly from 100% to 30%.

Fig. 4 Output modulation hystereses H1 and H2.

Once the actual boiler temperature has

reached the preset value, the regulator

enters SUPERVISION mode

8.8 SUPERVISION mode

The SUPERVISION mode occurs both during

operation with STANDARD, as well as with

Individual Fuzzy Logic control algorithm.

The regulator switches into the

SUPERVISION automatically, without the

user’s intervention:

- in the case of Standard control mode -

upon reaching preset boiler temperature,

- during Individual Fuzzy Logic control - upon

exceeding the preset boiler temperature by

5°C. In the Individual Fuzzy Logic mode, the

regulator strives to avoid switching the boiler

into the SUPERVISION mode, and to supply

as much heat, as the CH system requires at

the time.

In the SUPERVISION mode, the regulator

supervises the furnace, so that it would not

go out. For this purpose, the airflow and the

feeder are activated only for a while, rarer

than in the OPERATION mode. Without

causing further temperature increase.

The airflow does not work continuously,

it is activated cyclically together with

the fuel feeder, which prevents the

flame from going out during boiler

standstill.

All parameters regarding boiler setup in the

SUPERVISION can be found in the menu :

Service settings > Boiler settings >

Supervision

Parameters of the SUPERVISION mode

should be set in accordance with boiler

manufacturer’s recommendations. They

should be chosen in such a way, that the

furnace did not go out during boiler standstill

(at the same time, it should not fire up too

intensively, as this will trigger increase in the

boiler temperature). Duration of the feeder

operation and interval in the SUPERVISION

mode are set using parameters:

... > SUPERVISION > Feeding time

... > SUPERVISION > Feeder interval

Airflow extension time necessary to fire-up

supplied fuel is set in:

... > SUPERVISION >Airflow

oper.extend.

Loading...

Loading...