1

2

3

4

SYMPTOM

CAUSE SOLUTION

Motor fails to

start or kicks

on and off

A Plug the GFCI into a 3-wire grounded outlet and press the reset button to turn pump on.

B Reset circuit breaker on electrical panel. If problem persists, have an electrician check circuit.

C Check the line voltage, it must be in the range of 105 to 125 AC Volts.

No or slow

water flow

through the

return fitting.

Filter pump is

not cleaning

the pool

properly(Cloudy

water,

green…..etc.)

Water leakage

A Fill the pool to the fill line. The suction fitting must be at least 4” under water.

A Maintain chlorine level between 1.0 to 1.6 ppm.

B Maintain pH level between 7.3 to 7.8.

C Clean or replace the filter cartridge. (See page 12). Spare cartridges make service easier.

A Make sure hose clamps are positioned properly over the hose and o-ring to ensure a proper

D Inspect the filter cartridge for holes or tears. If visibly damaged; replace the filter cartridge.

E Check for obstructions(s) at the filter cartridge, suction fitting or return fitting.

F Have the pool water sample tested by a pool supply store. It may be necessary to add other

chemicals due to varying water quality in different localities.

G Chemicals are required to maintain clean pool water. Clean pool and filter more often.

B Check for obstructions(s) at the filter cartridge, suction fitting or return fitting.

A Unit Not Plugged In

B GFCI Outlet Breaker Tripped

C Low voltage

A Low pool water level

A Chlorine level

B pH level

C Dirty filter cartridge

D Damaged filter

cartridge

E Slow water flow

F Other chemicals

required

G Pool water very dirty

B Inlet/Outlet clogged

C Dirty filter cartridge

A At Suction/Return

B Vent Screw in Seal Top

C Seal Top

D Pump Base

C Clean or replace the filter cartridge. See page 12; A spare cartridge makes service more

convenient.

B Check O-ring 13 for damage. Replace if needed. Tighen the Vent Screw 12 .

C Check Canister Gasket 16 for damage. Replace if needed. Tighten the Seal Top 14 .

D 1) Check the Canister Gasket 16 for damage. Replace if needed. Tighten the Base 15 .

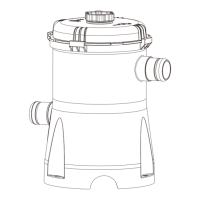

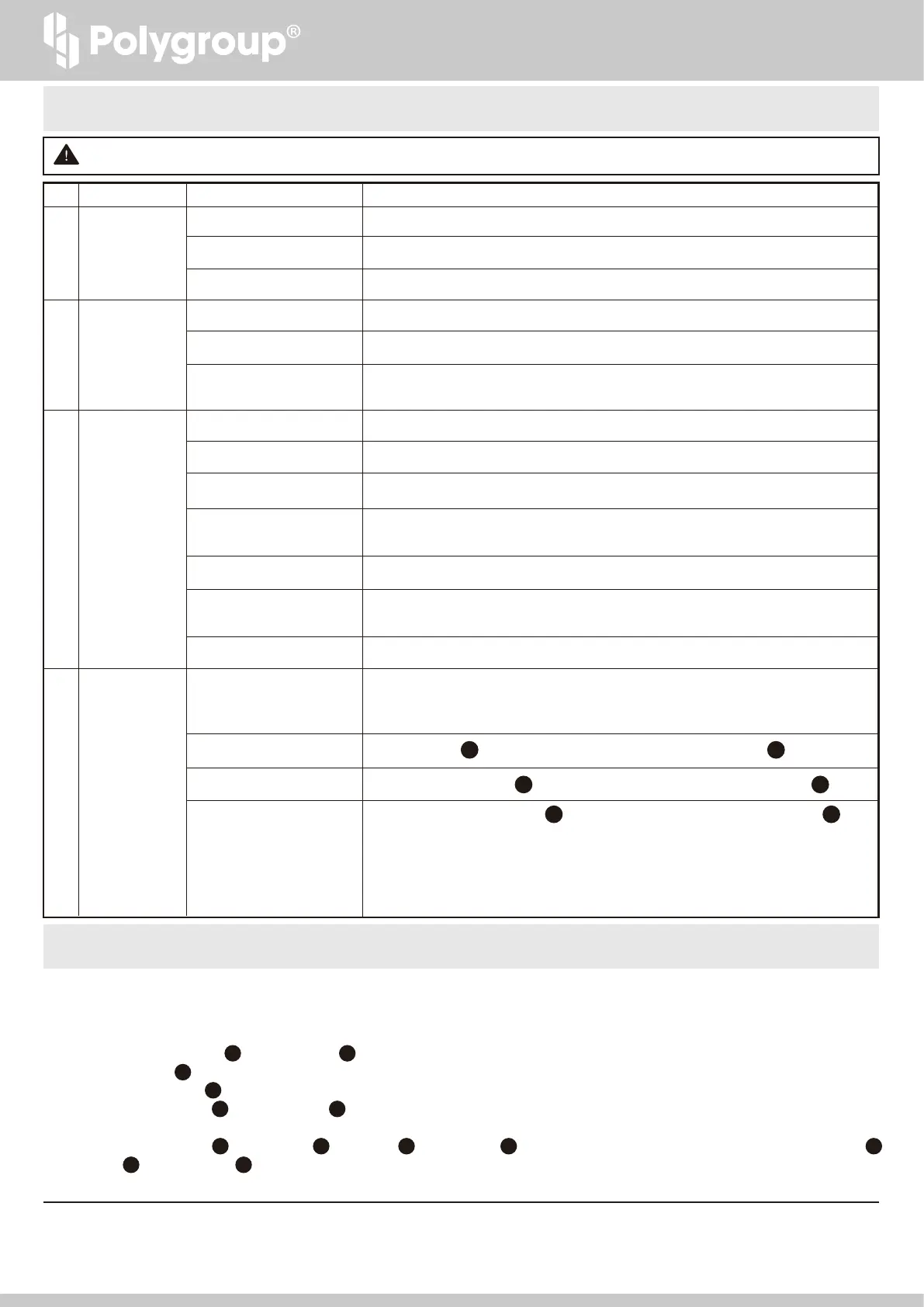

TROUBLESHOOTING GUIDE

POOL PUMP DISASSEMBLY & STORAGE

1. First, turn the pump off and unplug the main power cord of the system.

2. Remove the RF Diverter 7 from the Return Fitting 6 and then plug the Return Fitting 6 with the RF Plug 8 Now, hand tighten the SF Cap 5 onto the

Suction Fitting 2.

3. Slowly unscrew the Vent Screw 12 from the Seal Top 14 allowing the Filter Pump to depressurize.

4. Remove the Seal Top 14 by turning counter-clockwise.

5. Remove the Filter Cartridge 20 and remove any chlorine tablets left inside the core section of the filter.

6. Loosen all four Hose Clamps 10 , remove the Hoses 9 and allow any remaining water to drain out.

7. Clean and dry all filter pump parts including filter cartridges.

8. Liberally lubricate the O-rings 13 at the Seal Top 14 and Gasket 16 on the Canister 17 with petroleum jelly, and then reassemble it, along with the Seal Top 14 ,

Vent Screw 12 onto the Canister 17 . Store all parts carefully in an airtight plastic bag.

9. All items should be stored in a dry environment that remains above 32 degrees Fahrenheit at all times.

WARNING: TURN OFF THE PUMP AND UNPLUG THE POWER CORD BEFORE TROUBLESHOOTING THE FILTER PUMP.

14

Should you encounter any problems, contact Customer Service at (888) 919-0070 from 8 AM to 5 PM Mon. thru Fri.

MST. Extended operating days and hours during peak season requirements.

seal. Adjust hose clamp, check o-ring and re-tighten.

Check hose for any holes or cracks and replace if needed.

Fittings or Hose

connections

2) The Canister Gasket must sit in the groove in the bottom of the canister before

installing the pump.

3) Check pump alignment. The arrow with the indentation on the pump MUST point to

the matching indentation on the canister.

4) Make sure that the Pump Base is not cross threaded on the Canister.

Loading...

Loading...