2-2

2 Introduction

2.2 Measurement Principle

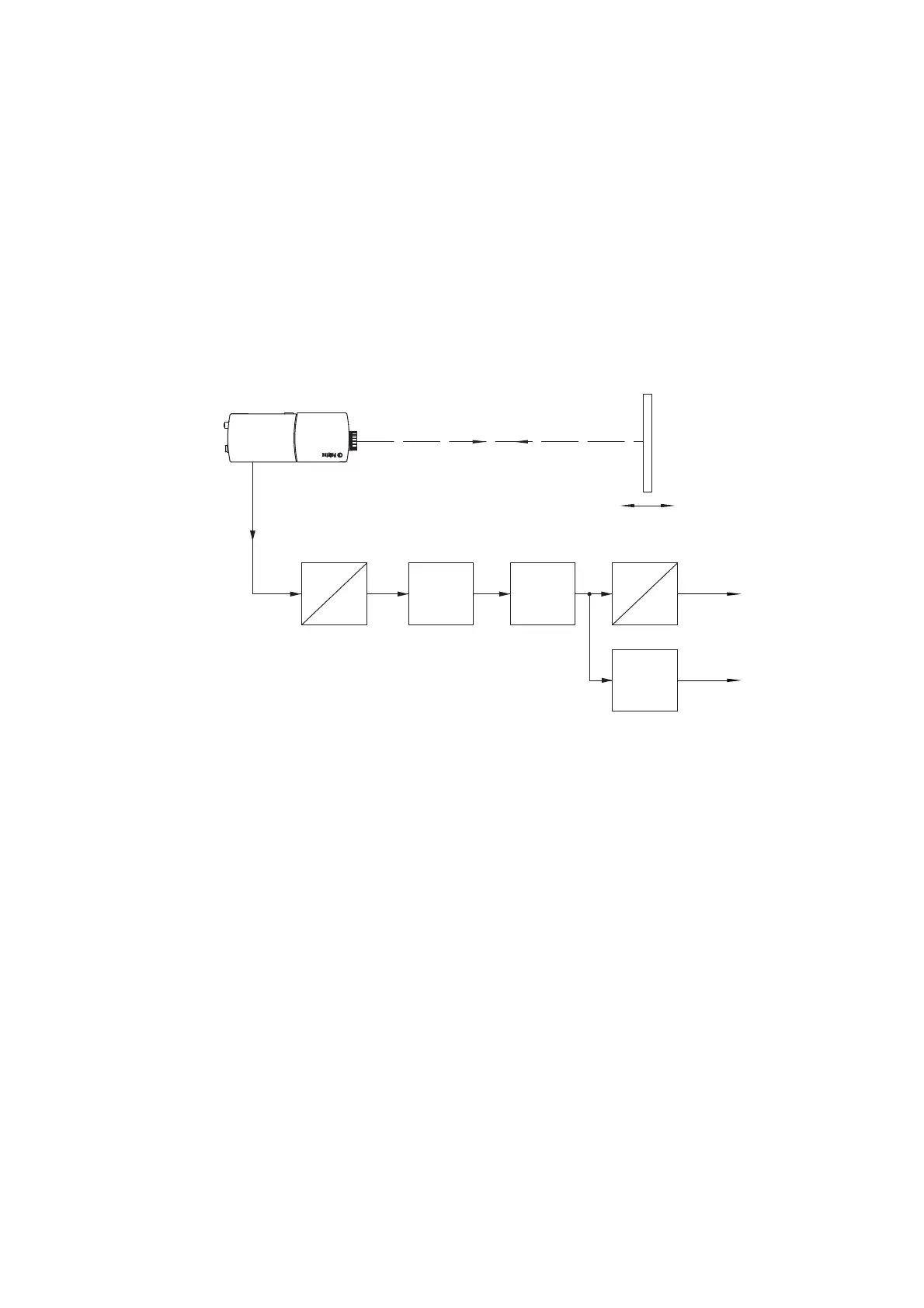

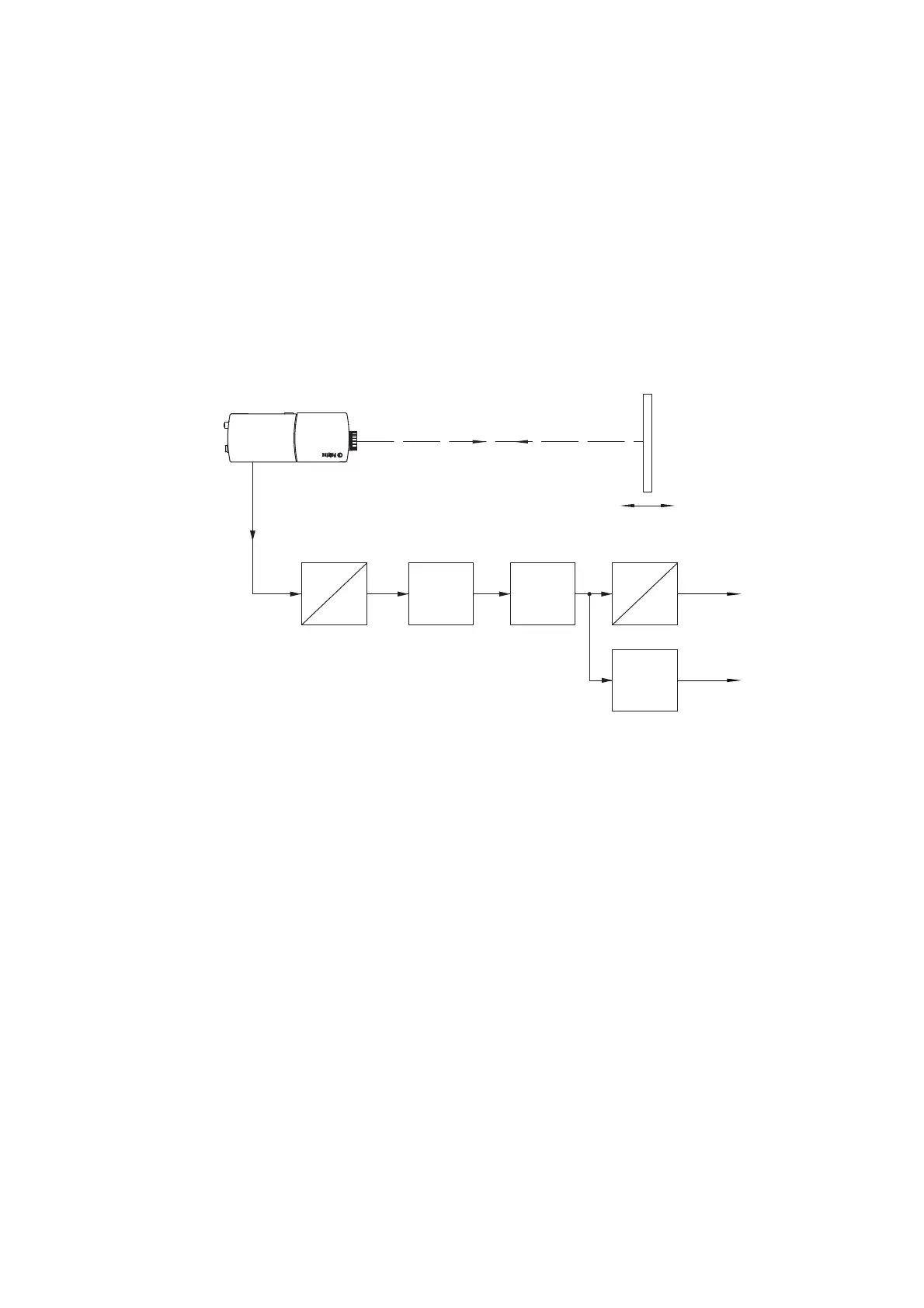

The PDV use the principle of the heterodyne interferometer to acquire the

characteristics of mechanical vibrations or transient motion processes (refer

to

APPENDIX

B). With this type of interferometer, a high-frequency carrier

signal is generated on the photo detector with the aid of a Bragg cell. To make

the vibration measurement, the beam of a helium neon laser is pointed at the

vibrating object and scattered back from it. The velocity amplitude of a

vibrating object generates a frequency modulation of the laser light due to the

Doppler effect. This modulation is recovered in the signal processing unit with

the aid of suitable demodulations (or decoders). A schematic layout of the

signal path is shown as a diagram in

FIGURE

2.2. The velocity information is

recovered from the frequency modulation of the Doppler signal.

Figure 2.2: Signals in the vibrometer

In the PDV, the optics and the signal processing unit are inside the housing.

The demodulation of the Doppler signal is purely based on a digital process.

In contrast to the conventional vibrometers which use analog, this then means

that the measurement accuracy is virtually independent of aging and

environmental influences. State-of-the-art DSP technology makes it possible

to realize excellent measurement system characteristics, despite the compact

design and minimal energy consumption.

By using a serial interface proven in digital audio technology, the output signal

ca be fed into the digital inputs of modern recording devices or signal

analyzers without any loss of accuracy. For the conventional type of signal

processing, an analog signal output with 24bit amplitude resolution is also

available.

Velocity

decoder

Object

s(t)

v(t) = ds/dt

Doppler signal fD

v(t)

D

f(t)

Filter

DSP

IVS-400

INDUSTRIAL VIBRATION SENSOR

u(t) ~ v(t)

LP

HP

A

D

Audio

transmitter

S/P-DIF

Loading...

Loading...