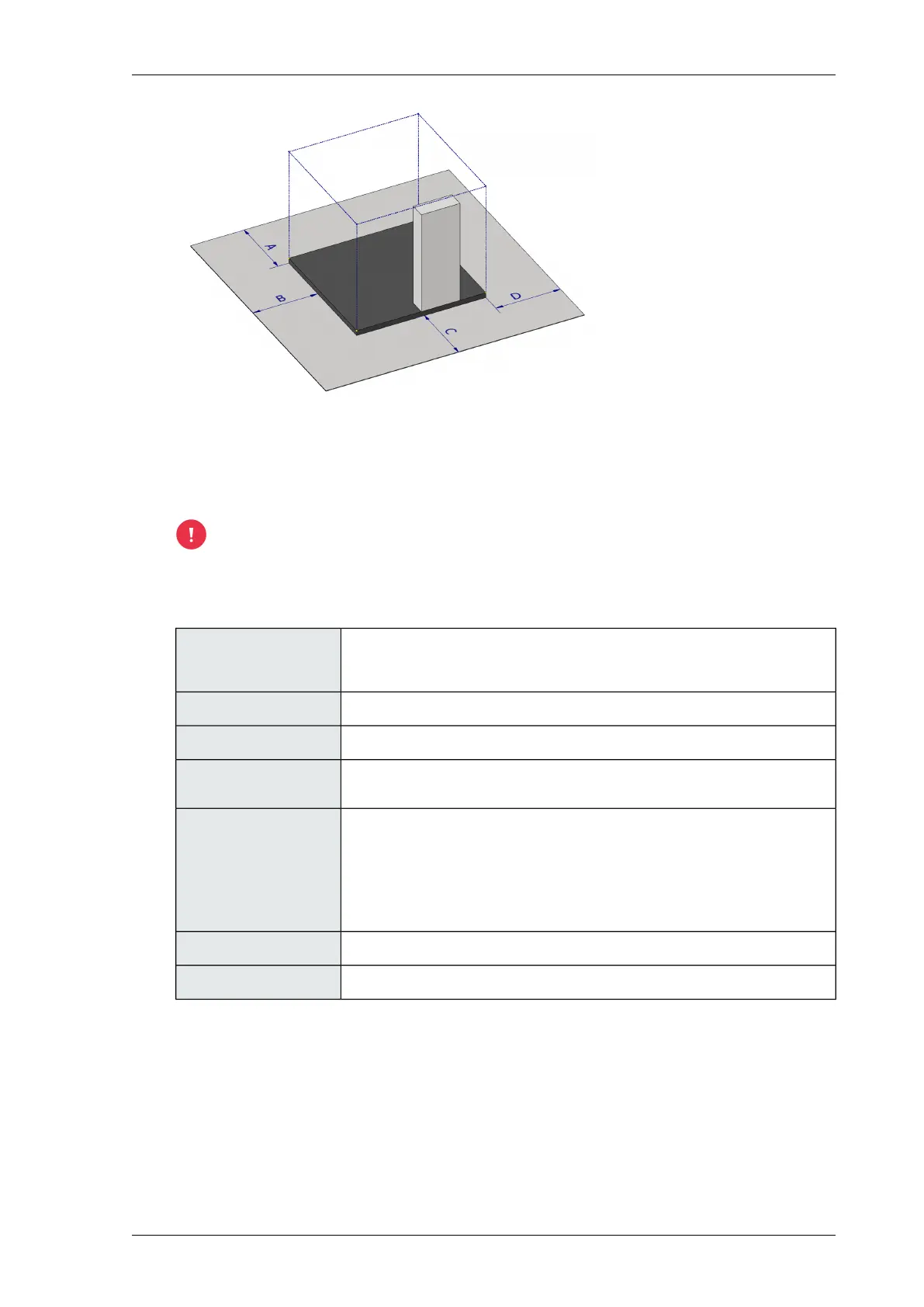

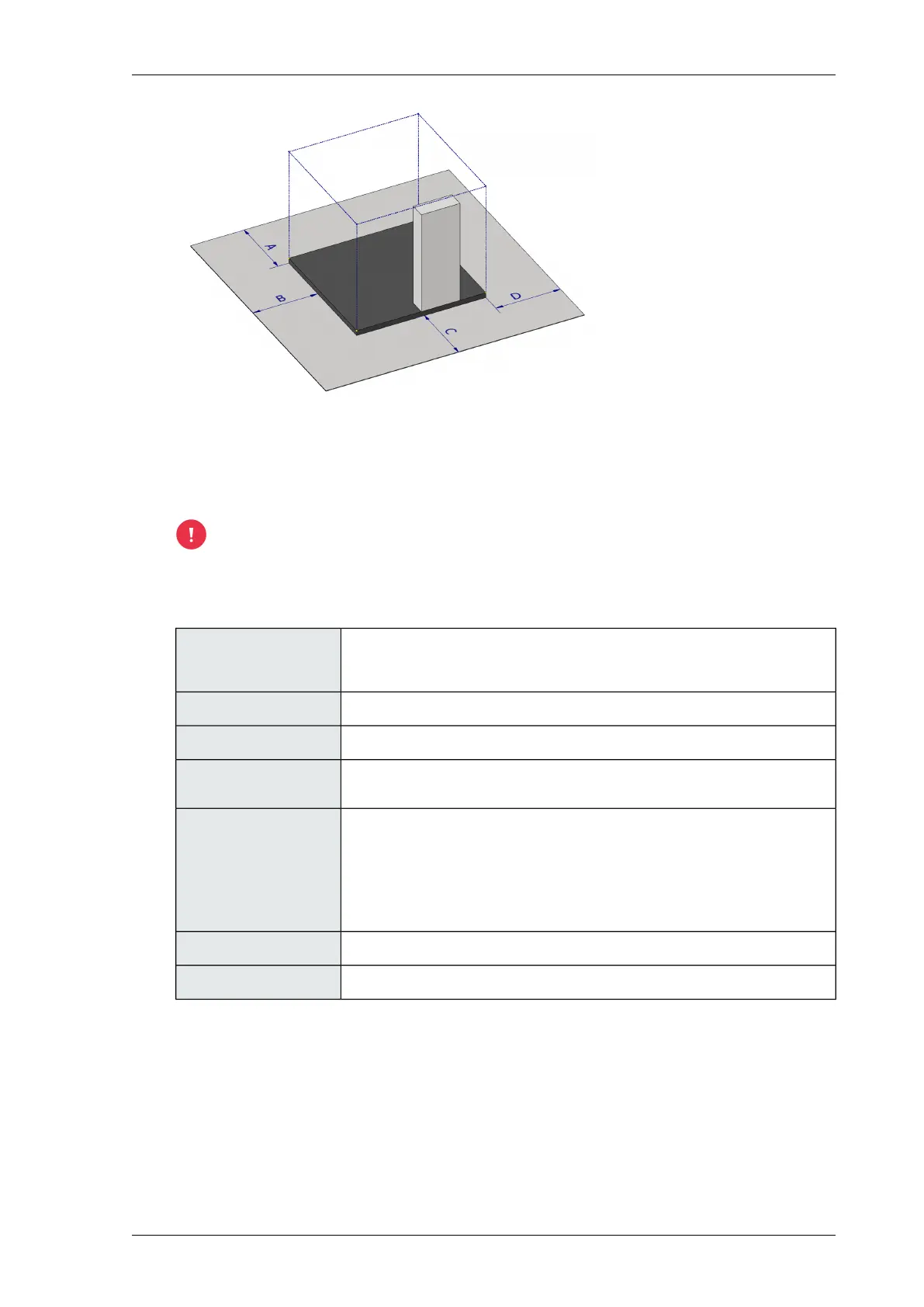

Required minimum space around unit

A = minimum 50 cm

B, C, D = minimum 110 cm

Environmental requirements

The unit must not be in direct sunlight. Due to bright sunlight the temperature will become

too high, causing plastic parts to deform, creating malfunctions in electrical components

and shortening the service life of electrical components.

Always keep any cabinet ventilation grilles free and open, allowing the electrical components

to be cooled.

Position the unit in an indoor, well-ventilated room, free from drips and splashes, with

a stable temperature (no rapid temperature changes).

Select a location where the unit cannot easily be damaged (e.g. by mobile equipment).

The surface on which the unit will stand should be hard, flat and level.

General

0 – 35 °C

As long as the unit contains water (residue) it must be kept frost-free.

Ambient temperature when

not operating

5 – 30 °CAmbient temperature during

operation

5 – 30°C (the unit can still work at a maximum temperature of 30°C. However, with

regard to the water quality and/or the operation of the unit, such a high water

temperature is generally unacceptable.)

Supply water temperature

< 85% (this is lower than the maximum relative air humidity during transport because

of the presence of chemical substances.)

Condensation will form on the pipe-work, particularly when relatively cold supply water

is used. This is very corrosive when combined with the vapours from the chemical

substances. Hose clamps and other metal parts must therefore be of corrosion-resistant

types of metals or must be well coated (and remain so).

The cabinet contains sensitive electronic circuits and must definitely remain

condensation-free.

Relative air humidity

1000 m above sea level (Cavitation may occur in the system pump when the ambient

pressure is too low.)

Maximum installation height

maximum 2 (normal, non-conducting pollution)Pollution factor (NEN-EN-IEC

61010-1)

Operating software

Refer to the relevant process computer software manual.

21NutriJet - user - 00.002

Operation

Loading...

Loading...