Maintenance and repair

• Carry out periodic maintenance in accordance with the preventative maintenance

schedule.

• Some maintenance activities may only be performed by authorised Priva installers/service

engineers who have received product-specific training from Priva. This is indicated in

the preventative maintenance schedule.

• Switch the unit off using the main disconnect switch before carrying out any maintenance

work. If the unit has to remain on within the scope of the maintenance work take extra

care.

• Only use original Priva spare parts.

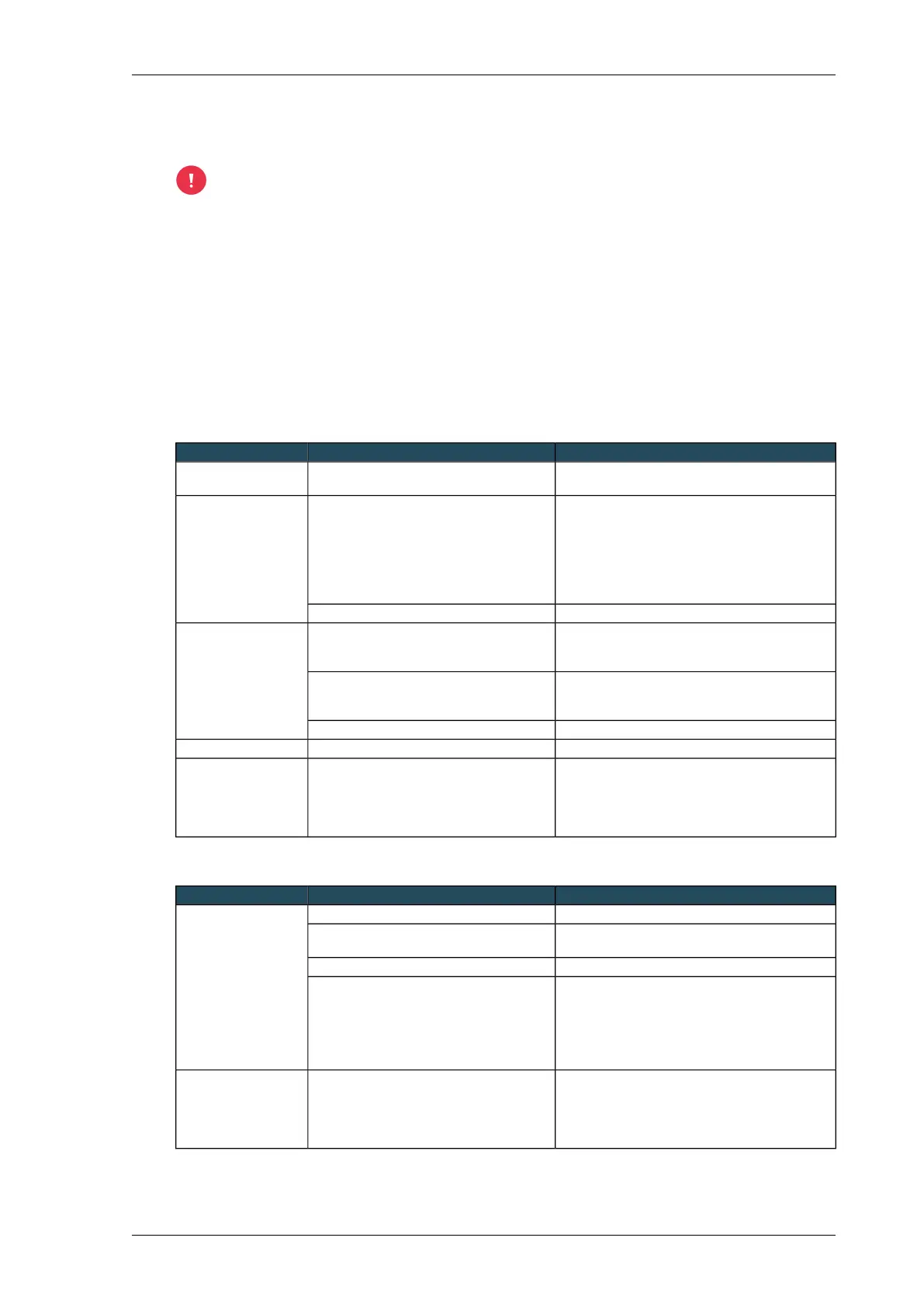

Preventative maintenance schedule

To be carried out by: user

ExplanationActionMinimum frequency

be alert for leaks and abnormal noises

(from the system pump)

always

1. For each irrigation valve, place a number of

drippers in plastic beakers.

check quantity of irrigation water to plantsweekly

2. After the irrigation cycle, add the content of

the beakers to a measuring beaker and read the

volume.

3. Divide this volume by the number of beakers

to determine the average volume per dripper.

See Cleaning the exterior of the unit (page 26).keep the unit and surrounding area clean

See Cleaning the inline dirt filter (page 27) and

Cleaning the dirt filter of the dosing channel (page

27).

clean dirt filters and other filtersmonthly

Test with system pump running and normal

consumption of irrigation water. See the pump

documentation for the correct pressure.

check system pump pressure (via

manometer on pipe-work to venturis)

See Cleaning the pH sensors (page 28).pH sensors: check operation and clean

See Cleaning the flow sensor (page 30).flow sensor: check operation and cleanannually

Refer to the documentation for the relevant

equipment.

maintenance of external equipment

connected to the unit (e.g. a light sensor)

dependent on

equipment

Whether this action must be performed by the

user or installer/service engineer depends on

the equipment.

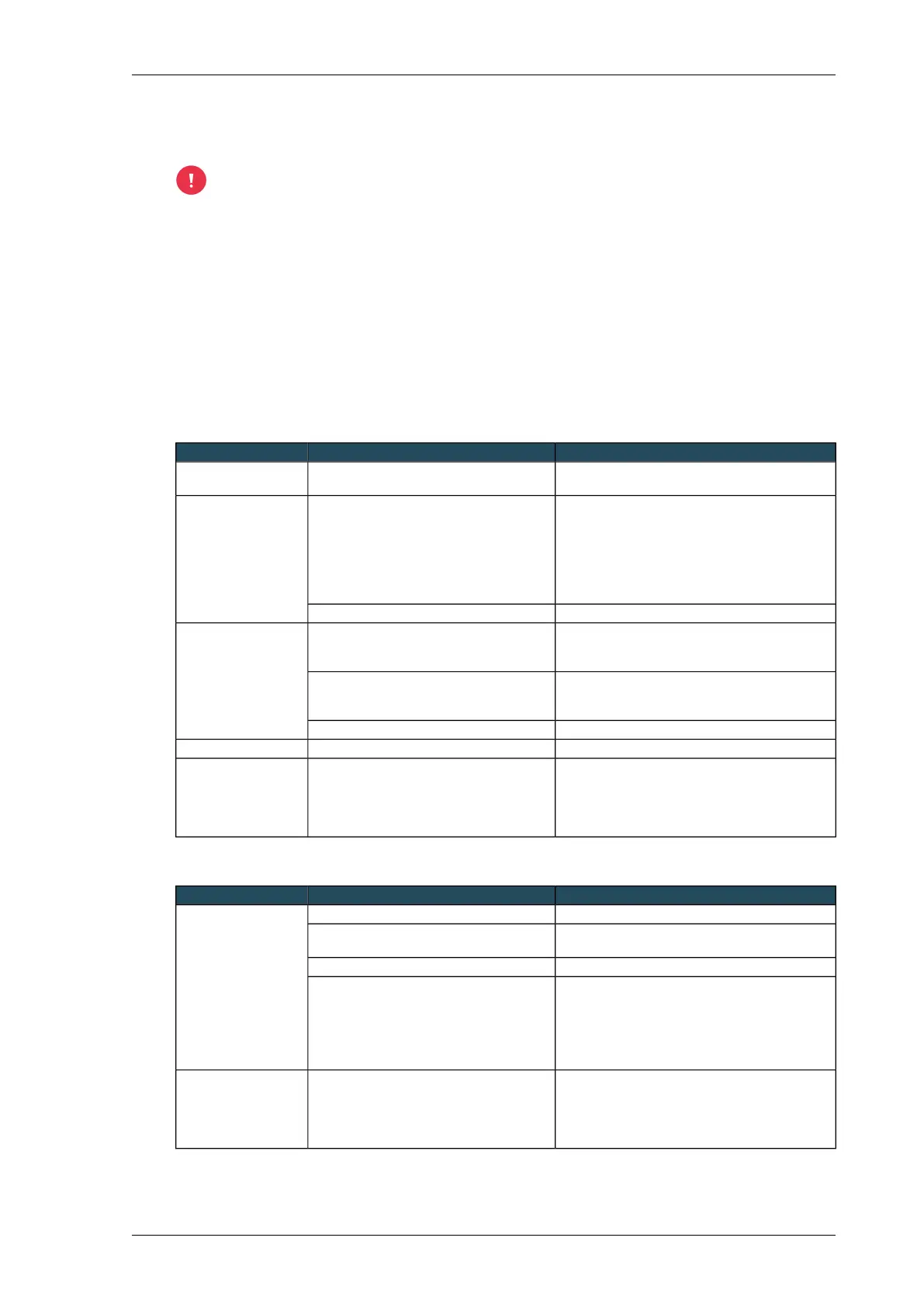

To be carried out by: installer / service engineer

ExplanationActionMinimum frequency

See EC-sensoren reinigen.EC sensors: check operation and cleanannually

See Rotameter van doseerkanaal reinigen.rotameters on dosing channels: check

operation and clean

See Meststofaanzuiging controleren.dosing channels: check operation

1. Close the manually operated valves in the

supply line and main irrigation line.

clean sprinkler pipes in mixing chamber

2. Open the drain point of mixing chamber and

let the unit run dry.

3. Open the mixing chamber and clean the

sprinkler pipes.

Refer to the documentation for the relevant

equipment.

maintenance of external equipment

connected to the unit (e.g. a light sensor)

dependent on

equipment

Whether this action must be performed by the

user or installer/service engineer depends on

the equipment.

25NutriJet - user - 00.002

Maintenance and repair

Loading...

Loading...