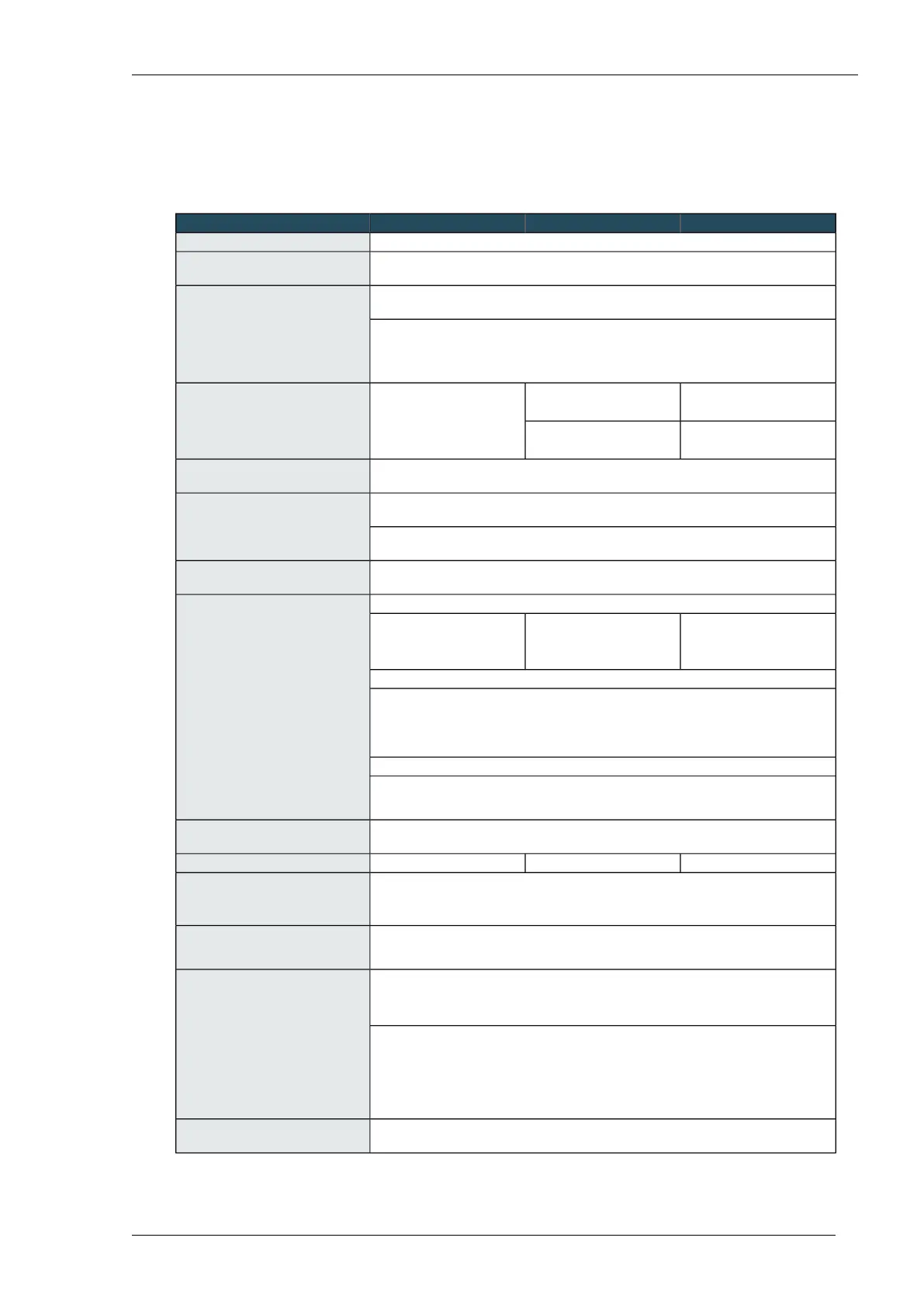

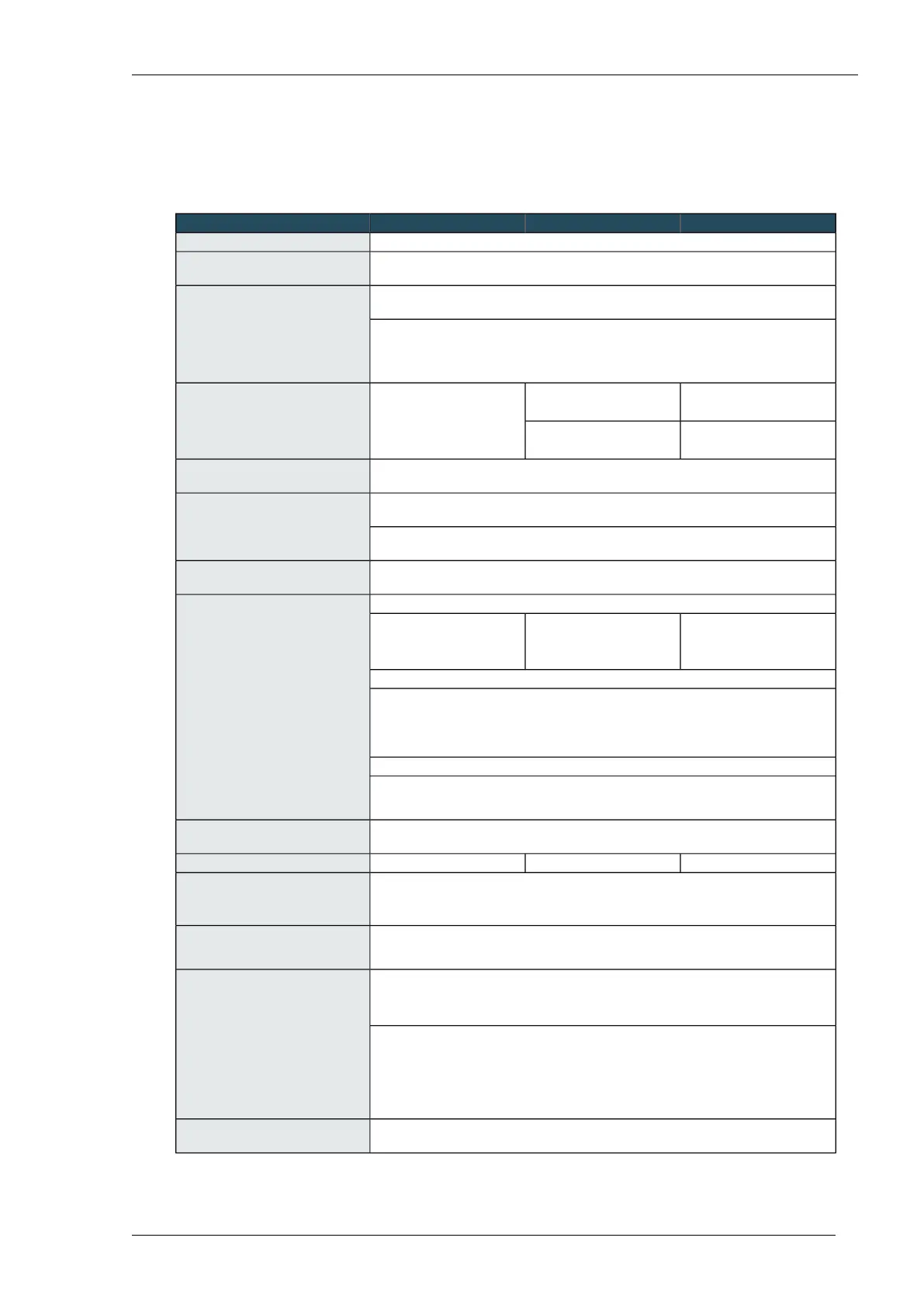

Technical specifications - Product options

Technical specifications – general

NutriJet 600NutriJet 300NutriJet 100

closed mixing chamber(s)Principle of operation

A + B principle (equal quantities of fertilisers)Fertiliser mixing principles

ABC-principle (adjustable ratio of fertiliser quantities)

NutriJet Inline:Basic configurations

All the water in the supply line flows through the unit.

NutriJet Bypass:

Some of the water in the main line is directed via the unit and then injected back

into the main line. The unit delivers a concentrated fertiliser solution that mixes

in the main line with the other water in the main line.

NutriJet Inline:NutriJet Inline:NutriJet Inline:Pump capacity

22 - 79 m

3

/h8 - 41 m

3

/h3 - 26 m

3

/h

NutriJet Bypass:NutriJet Bypass:

15 - 78 m

3

/h8 - 26 m

3

/h

The net irrigation capacity depends on the selected configuration. See configuration

tooling.

Irrigation capacity

NutriJet Inline:Permissible supply water pressure

0.1 - 0.4 bar above atmospheric pressure

NutriJet Bypass:

3 - 6.5 bar above atmospheric pressure

7 bar above atmospheric pressureMaximum permitted pressure in

system

EC dosing channels:Possible types of dosing channels

• 600 l/h dosing channel

• 600 l/h double dosing

channel

• 300 l/h dosing channel

• 300 l/h double dosing

channel

• 100 l/h dosing channel

• 100 l/h double dosing

channel

pH dosing channels:

• 100 l/h low acid up to 10%

• 300 l/h low acid up to 10%

• 50 l/h high acid up to 38%

• 50 l/h lye KOH up to 50%

Low-volume dosing channels:

• 2 m³/h

• 8 m³/h

2x 5Maximum number of dosing

channels

200 mm160 mm110 mmDiameter of mixing chamber

In the configuration of the installation, the system pump is selected on the basis

of various criteria. System pumps are available with various capacities and for

various mains voltages and mains frequencies.

1)

System pump

• overload protection based on motor protection

• softstarter on pump

System pump protection

NutriJet Inline:

• 1 manometer for drive water on venturis (discharge side of system pump)

• 1 manometer for suction side of system pump

Manometers for visual pressure

check

NutriJet Bypass:

• 1 manometer for drive water on venturis (discharge side of external pump)

• 2 or 3 manometers (depending on the number of pressure reducing valves)

for checking the incoming pressure of the mixing chamber(s)

• 1 manometer for suction side of system pump

• 1 manometer for outgoing unit pressure (discharge side of system pump)

See the EC Declaration of Conformity.Regulations and standards with

which the unit complies

NutriJet - user - 00.00244

Priva

Loading...

Loading...