M-34-01-06 3/31/2016 12 DQ15D/T-DQ15D Manual

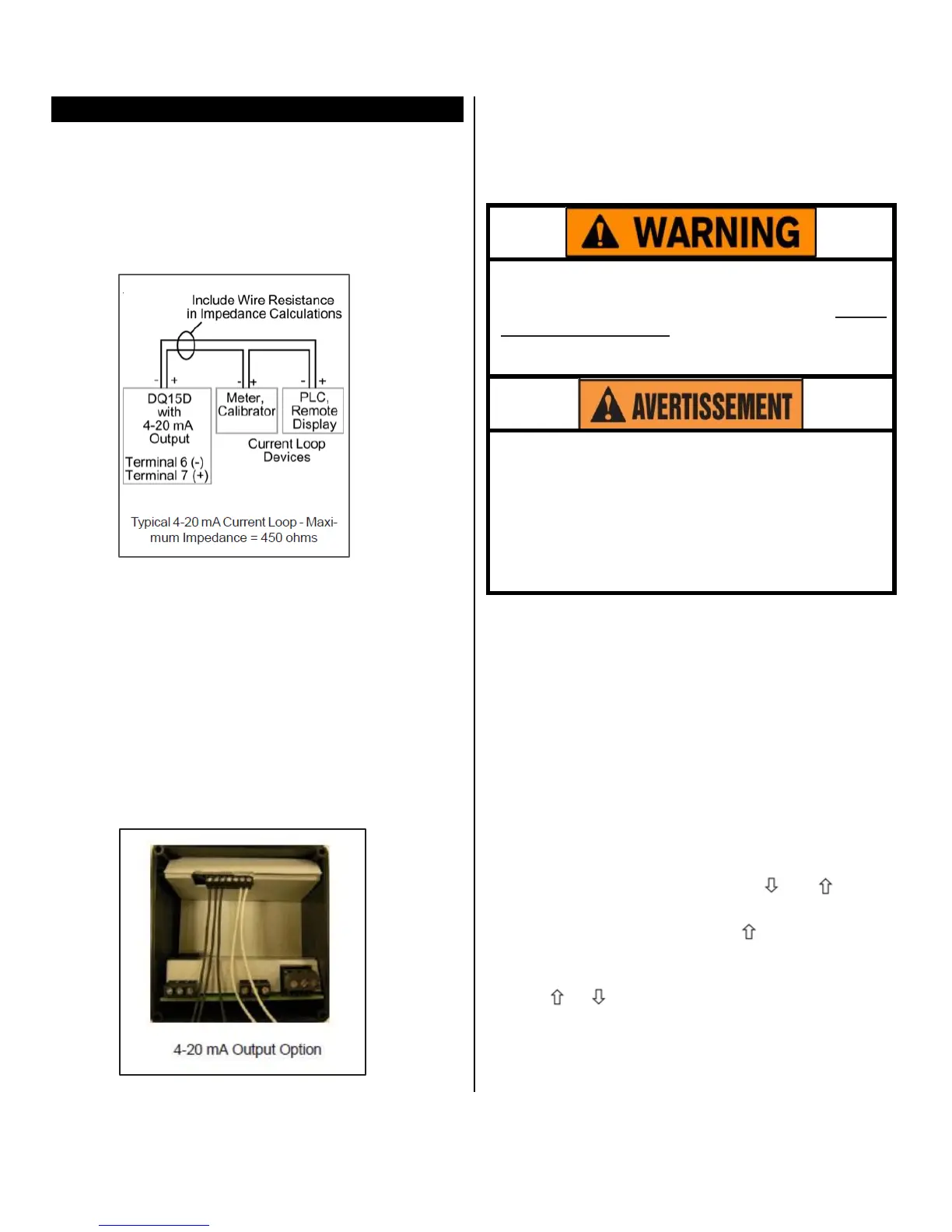

4-20 mA Output (“-M” Option)

The DQ15D is available with an optional 4-20 mA

output signal

propor

t

ional

t

o

t

he

me

a

su

r

e

d (displayed)

temperature. This option is useful for source transmit-

ting the

measured temperature to a current loop-

sensing device such as a PLC, remote intelligent dis-

play or chart recorder. Use Terminals #2 and #3 for 2

wire 1000 ohm RTD.

Factory calibration is verified using an intelligent NIST

traceable 4 digit DMM, a NIST traceable sensor cali-

brator, and an intelligent display.

The factory range setting is 0-500° F vs. 4-20 mA.

Custom ranges can be accommodated if specified at

time of order. Field calibration can use a similar ar-

rangement or a 4-20 mA calibrator for verification.

Since calibration is an involved operation, it is sug-

gested that it be performed only after determining that

the measured values differ from factory settings, or if

the output range is to be altered.

Use Terminals #2 and #3 for 2 wire

1000ohm RTD.

Equipment needed:

• Item #5416 or 5419 board.

• An NIS T traceable sensor simulator (calibrator

),

a precision

20

mA or higher calibrator/tester, or a

precision DMM for

ve

r

ificat

ion

.

Calibration procedures require the removal of

the rear cover of the

control.

It also requires that

power is ON, exposing the technician to poten-

tially lethal

voltages.

Exercise

EXTREME

CARE

and

wear tested electrician’s gloves whenever

power is on.

Les procédures de calibration nécessitent

l'enlèvement du panneau arrière du contrôle.

Ça exige aussi que le courant électrique est

allumé ce qui expose le technicien à des ten-

sions potentiellement létales. Utilisez toujours

un soin extrême et portez des gants certifiés

d'électricien quand le courrant est allumé.

Calibration Procedure:

1 Turn OFF all power.

2 Remove rear cover.

3 Remove sensor leads.

4 Install appropriate sensor calibrator, i.e. resistors

or thermocouple simulator.

5 Remove ONE lead of the 4-20 mA output wire and

install the DMM or tester in series with the external

loop and this terminal. OBSERVE POLARITY.

6 Restore power to control.

7 Verify basic instrument sensor input accuracy by

simulating various sensor inputs and observing the

display values. If out of tolerance, perform appro-

priate sensor calibration before proceeding.

8 Simultaneously press and hold and for ap-

proximately 6 sec. The screen displays AC.0.

While the 0 is flashing, use to enter 33. The

screen changes to display L followed by the cur-

rent lower process limit, i.e. 0°, -20°, 0V, etc.

9 Use or to alter the lower display value. Press

SET to store the new value. The display will then

read hexadecimal 2AAA or 4.0mA, verify that this

is the value displayed on your

4-20 mA calibra-

tor/tester or DMM.

Loading...

Loading...