M-34-01-06 3/31/2016 8 DQ15D/T-DQ15D Manual

3 Wire RTD Sensor Calibration (Continued)

8 Press and simultaneously and hold for ap-

proximately 6 sec. The screen displays AC.0.

While the 0 is flashing, use to change this to 22.

Press SET. CAL1displays.

9 Press and hold SET for one sec. The screen dis-

plays Hold. Wait for the message to change to

CAL2.

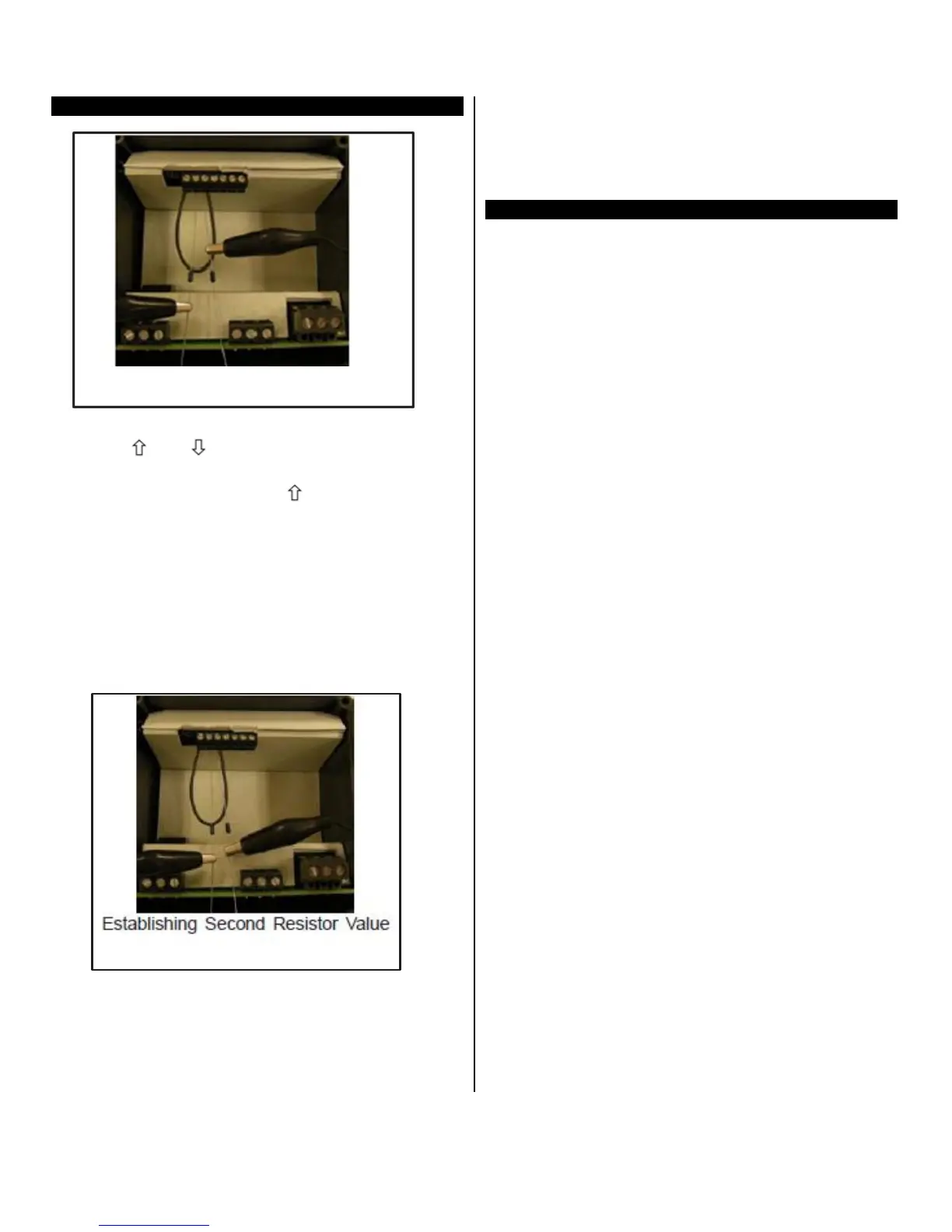

10 Proceed with CAUTION to avoid SHOCK hazard.

Remove and relocate one end of the jumper cable

to the loose end of the second precision resistor

for the second resistance value (i.e. 2000 ohms or

200 ohms), as shown.

11

12 Press and hold SET for one second. The screen

displays Hold. Wait for the display to reset. After it

resets, the approximate temperature value for the

connected precision resistors should display (i.e.

511° F or 266°C).

13 Turn OFF power to the controller and remove the

precision resistors. Retain for future use. Reinstall

the RTD sensor and rear cover of controller. Re-

turn the calibrated controller to service.

Resistance Signal Calibration

This section describes how to configure and cali-

brate DQ15D to measure pure resistance.

Equipment

needed

Refer to the calibration procedure for the 2 wire

RTD sensor for equipment needed.

Calibration

Procedure

1 From the setting configuration mode, set the U1

sensor type parameter to 12. See

Configuration

(Setup).

2 Follow the Calibration

Procedure for a 2 wire RTD

sensor. DQ15D will then measure pure resistance

from 0-1000 ohms.

Loading...

Loading...