M-34-01-06 3/31/2016 4 DQ15D/T-DQ15D Manual

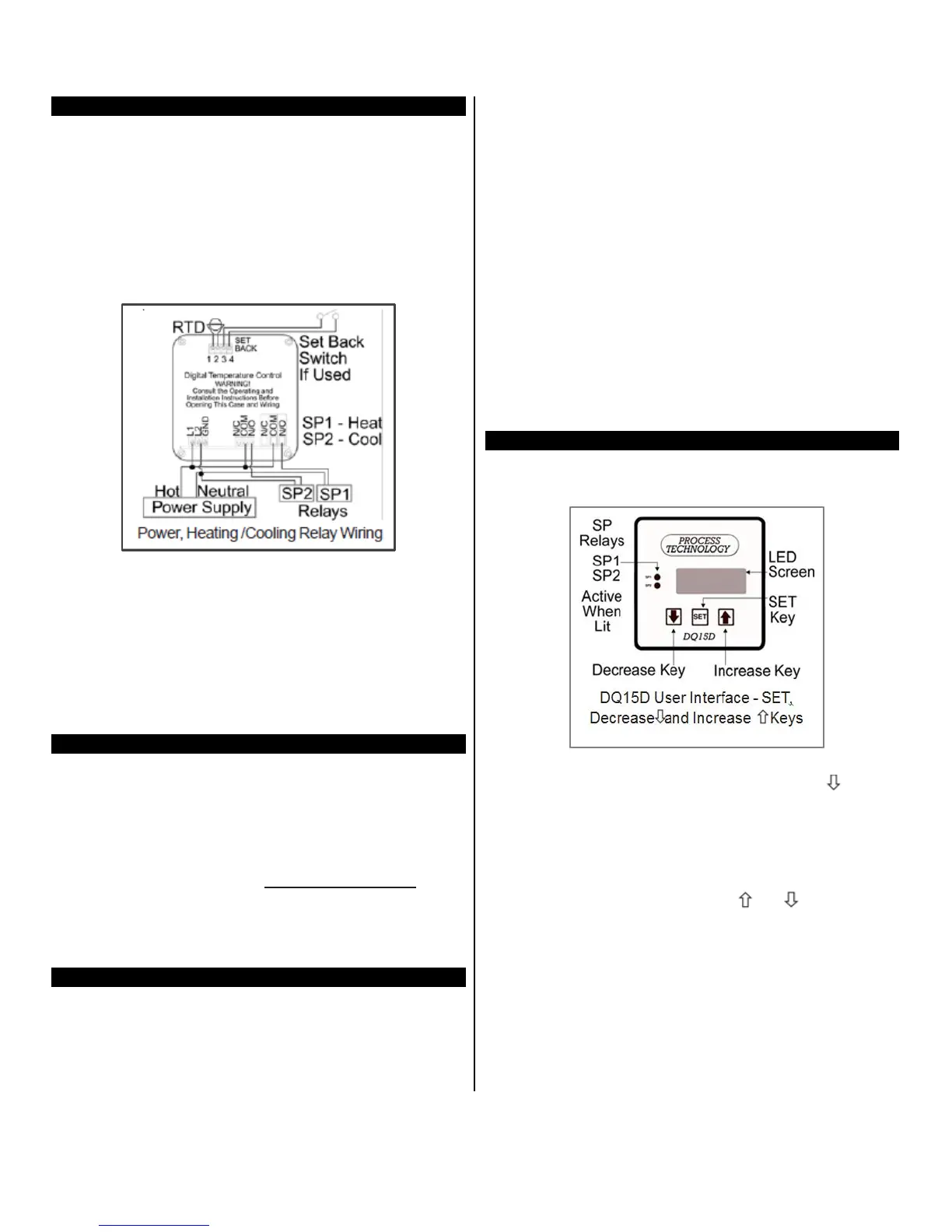

Power and Relay Wiring Procedure

Unit is intended for a single power source. To com-

plete the wiring procedure, you will need these tools

and materials:

1. #2 Phillips head screwdriver.

2. 1/8” (x-small) straight blade screwdriver.

3. Power supply wire, 18 awg minimum.

4. Relay connection wires (see state and local elec-

trical requirements for proper 65ºC wire gauge).

Referring to the “Power, Heating and Cooling Relay

Wiring (rear view of controller)” illustration above, lo-

cate and identify terminal locations for the power sup-

ply voltage, the set point relay, and the appropriate

sensor. Connect wires into their designated terminals

and tighten the retaining screw which will secure the

wire into place.

Extending Wiring

The factory supplied 1000 ohm RTD sensor can be

extended using standard electrical hookup wire (22

awg or larger). The effect of additional 22 awg sensor

wire length on control calibration is approximately 1ºF

for every 65 feet.

Note:

This does not apply

to

THERMOCOUPLES.

You

MUST use specific

thermocouple wire when

extend-

ing the sensor wire length. Use of incorrect exten-

sion wire can cause hazardous operating

conditions.

Relay Control Set Points

Before operation, you must program Set Points or tem-

perature limits.

When DQ15D reaches the Set Point it will energize one

or both relays.

SP1 Heat Set Point for normal Heating Mode opera-

tion. Controls SP1 relay.

SP2 Cool Set

Point

for normal Cooling Mode opera-

tion. Controls

SP2 relay.

P Power Save Set Point for a second heating Set

Point

lower than SP1 Heat Set Point. Optional; you

must enable Power Save

feature. Controls SP1 relay.

A Alarm Set Point to establish an Alarm Condition if

temperature reaches the

Alarm

Set Point (higher

than SP1 Set Point). The screen displays a flashing

AAA in

an Alarm Condition. Optional; you must ena-

ble Alarm feature.

Controls SP1 and SP2 relays.

Note: The units displayed, ºC, ºF, Hz, volts, mA or

ohms are established during the setup of the con-

troller.

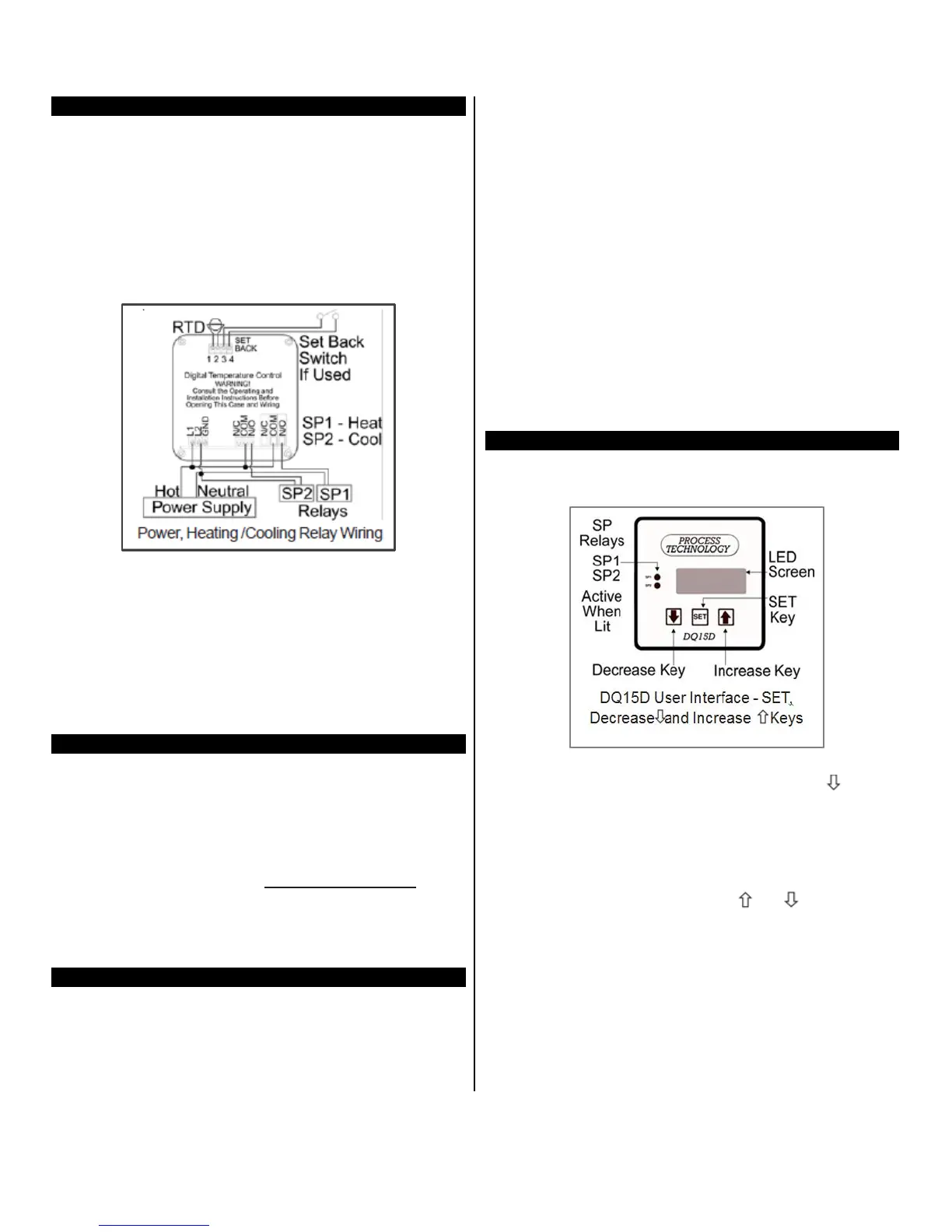

View/Change Set Points

The screen normally displays the actual process

temperature.

SP1 - Heat Set Point

1 To view the SP1 SET POINT value, press once

and release. For seven seconds, the letter H and a

decimal point followed by the numeric SP1 value

display. (After seven seconds the display returns

to normal.)

2 To alter the Set Point value, press SET while the

Set Point value displays (value will flash).

3 Once the value flashes,

use

or to change

the value.

4

Within 5

seconds

after changing the value, press

SET again to lock the new value into memory.

Note: If the “SET” key is not pressed within 5 sec-

ond

s

,

t

h

e

n

e

w

va

lu

e

will

b

e

lo

st a

nd

t

h

e set

poin

t value

will revert to its previous setting.

Loading...

Loading...