DCM 2 Installation

Page 10

2.2.1. Sample Connections

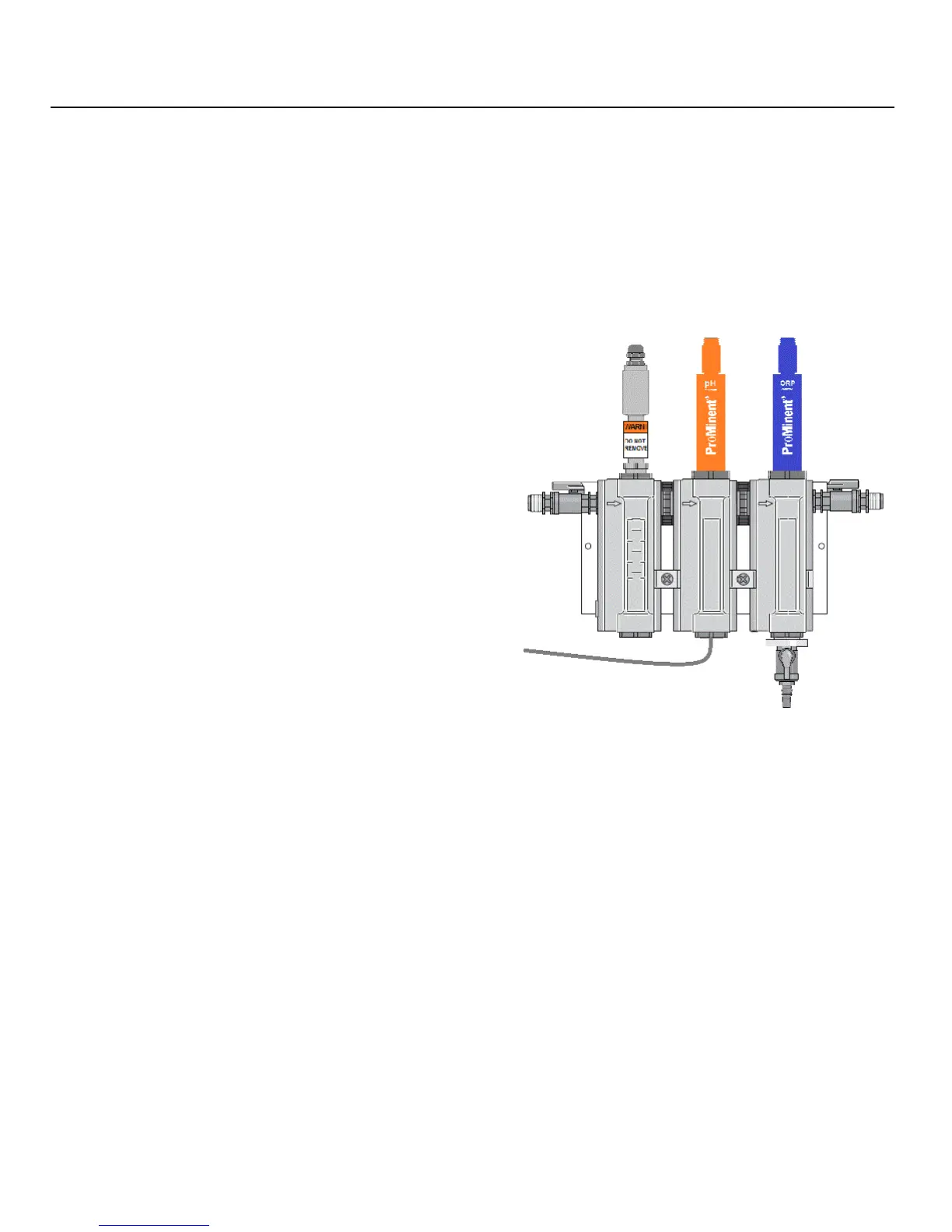

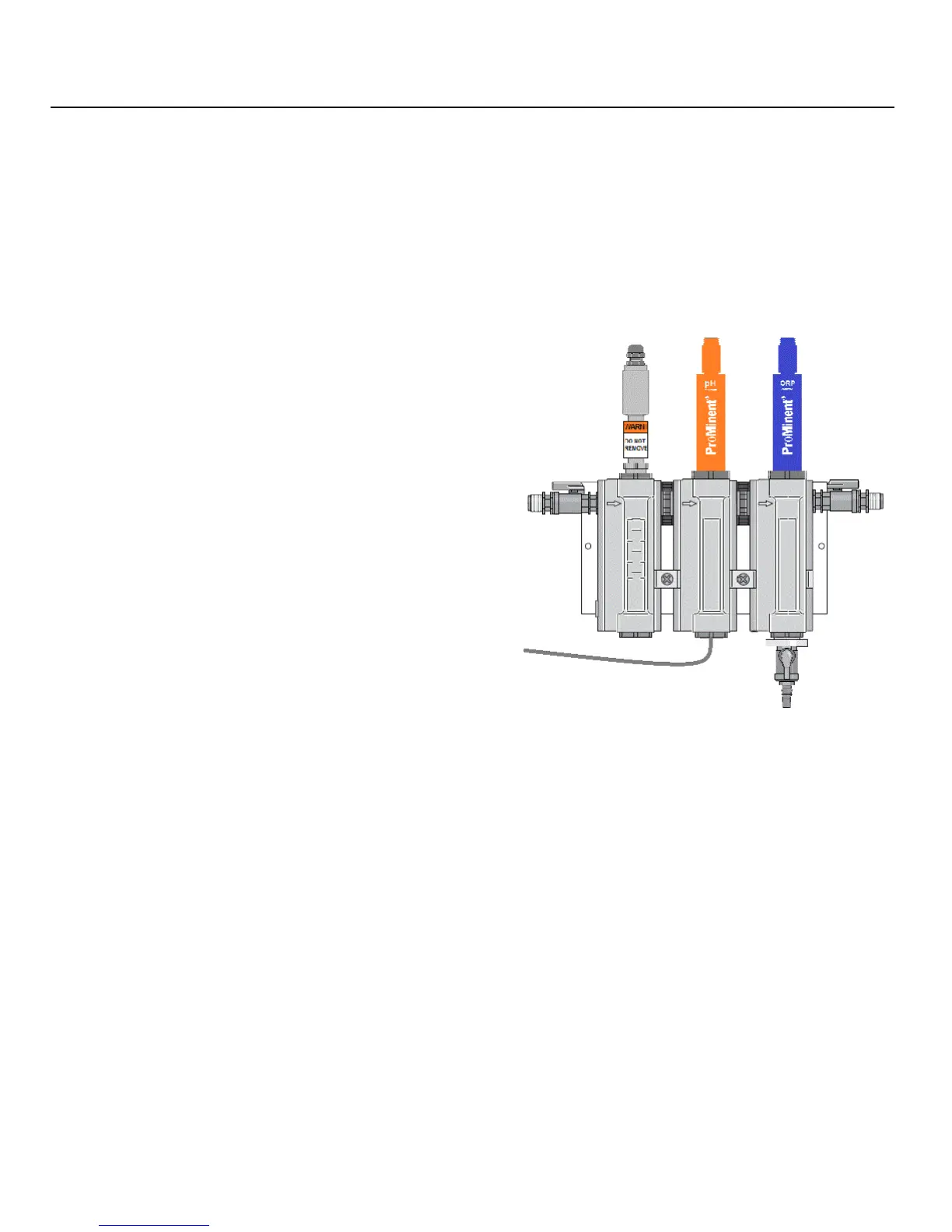

Modular Sensor Housing (DGMa)

• When shipped separately, the DGMa Sensor housing is mounted to a small white acrylic

backpanel.

• Mount plate within 60” of the DCM2 controller, and allow at least 18” clearance above the top of

the mounting plate. Do not mount in direct sunlight as this will promote algae growth and create

temperature swings not representative of the pool or spa under control.

• Using the typical installation drawings on the following pages, connect sample tubing to the DGMa

modular sensor housing and the main recirculation lines, using the fittings supplied.

NOTE: The default mounting of the modular

housing is to flow from left to right (note the flow

direction molded into each module).

• If preferred, the modular housing is

reversible by removing the assembled

modules from the black upper snap clips.

• First disconnect the spacer standoff

brackets and pull the module assembly to

unsnap it from the upper clips.

• Once it is loose, simply flip the assembled

modules so that the molded arrows on the

modules are pointing right to left,

• Then reconnect it to the standoff brackets

and remount onto the backpanel.

Adjustment of the standoff brackets

mounting screws may be needed.

• Next, use the typical installation drawing

below as a guide, and connect the sample

supply and return tubing using the selection

of fittings supplied.

NOTE: Keep in mind that a very small sample volume (11-12 GPH) is needed for ProMinent

controllers. That is only (0.18 GPM) compared to other aquatic controllers requiring 1-3 GPM.

Sensor sample should always be taken from downstream of the filter, but up stream of UV or

Ozone treatment system, heater and any chemical injection. Discharge sample into the line

returning to the pool or spa as close to the pool as possible to get the maximum pressure

differential. Using the pressure drop created by other devices like heaters or the UV system works

best.

CAUTION: Never take the sensor sample from unfiltered water as this may introduce hair or other debris into the

flow switch and sample cell. Never return sample to the suction side of the recirculation pump as this will cause a

negative pressure environment (vacuum) for the sensors, which will cause non-warranty damage to the sensors,

and more importantly, will cause erroneous readings and poor water quality control.

Loading...

Loading...