6 Assembly

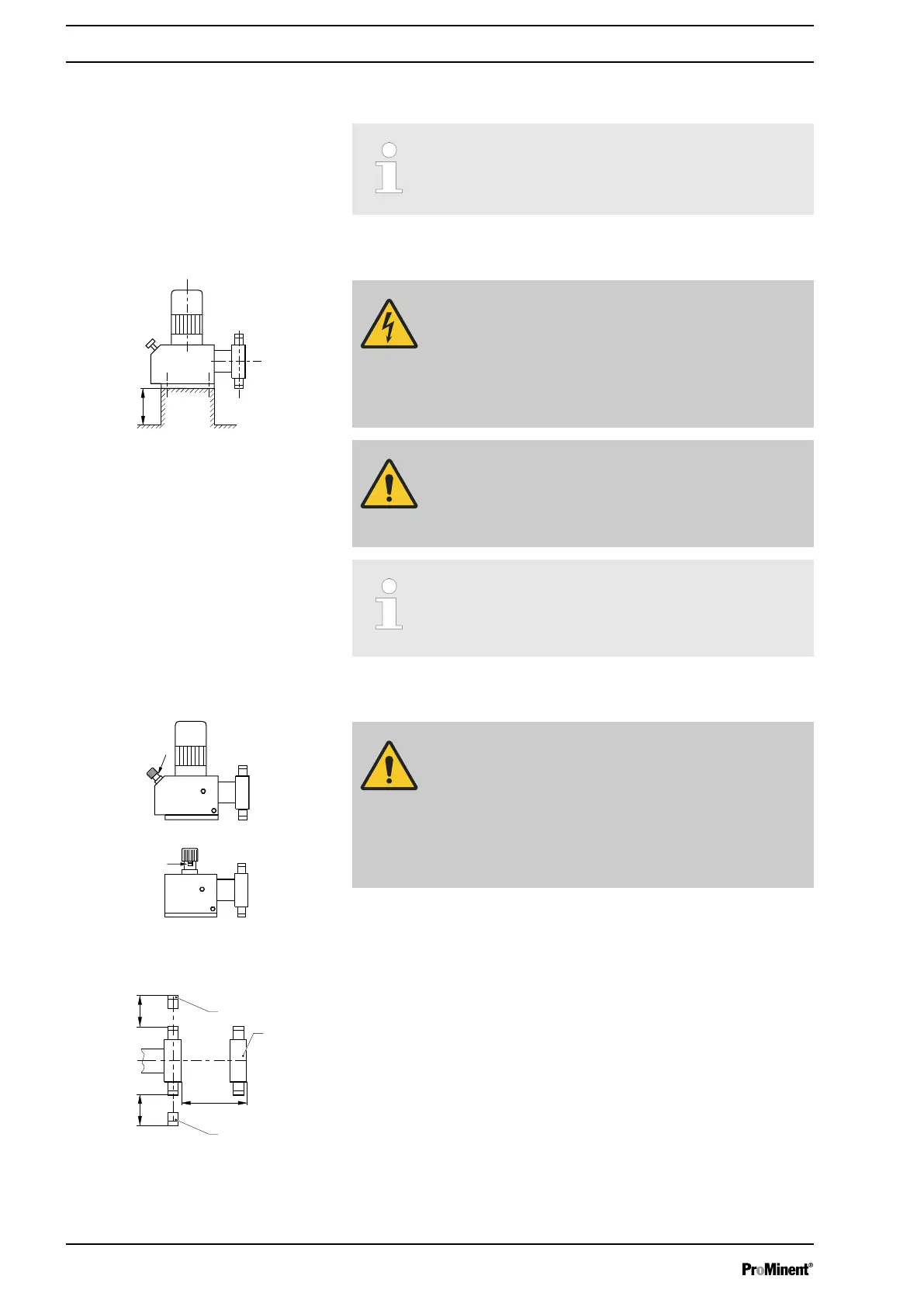

Compare the dimensions on the dimension sheet with

those of the pump.

WARNING!

Danger of electric shock

If water or other electrically conducting liquids penetrate

into the drive housing, in any other manner than via the

pump's suction connection, an electric shock may occur.

– Position the pump so that it cannot be flooded.

WARNING!

The pump can break through the base or slide off it

– Ensure that the base is horizontal, flat and perma‐

nently load-bearing.

Capacity too low

Vibrations can disturb the liquid end valves.

–

Do not allow the base to vibrate.

CAUTION!

Danger from incorrectly operated or inadequately main‐

tained pumps

Danger can arise from a poorly accessible pump due to

incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

–

Adhere to the maintenance intervals.

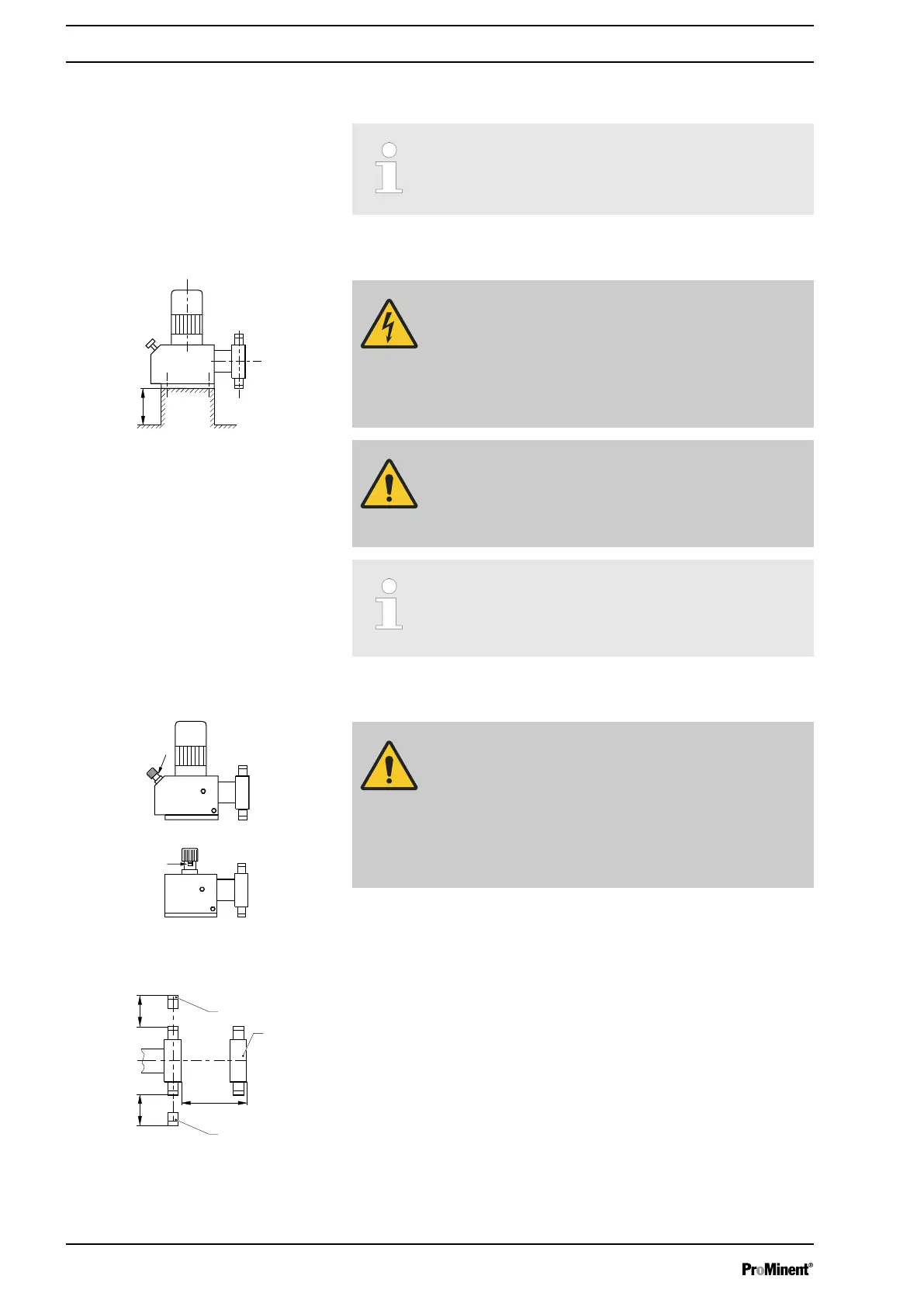

Position the pump so that control elements such as the stroke length

adjustment knob or the indicating dial A are easily accessible.

If the HMI is mounted remotely from the pump: a clearly marked Stop

mechanism must be installed in the direct vicinity of the pump for emer‐

gencies!

1 Discharge valve

2 Dosing head

3 Suction valve

Ensure there is sufficient free space (f) around the dosing head as well as

the suction and discharge valve so that maintenance and repair work can

be carried out on these components.

Base

Fig. 12

Space requirement

Fig. 13

Fig. 14

Assembly

24

Loading...

Loading...