CAUTION!

Warning of leaks

Leaks can occur on the pump connection depending on

the insert used.

– The pump is supplied with PTFE moulded compo‐

site seals with a flare, which are used for the pump

connectors, which seal the connectors between

grooved pump valves and ProMinent grooved

inserts - see

Ä Further information on page 26

.

– Use an elastomer flat seal in the event that an

unflared insert is used (e.g. third party part) - see

Ä Further information on page 26

.

–

Precise metering is only possible when the back

pressure is maintained above 1 bar at all times.

–

If metering at atmospheric pressure, a back pres‐

sure valve should be used to create a back pressure

of approx. 1.5 bar.

CAUTION!

Warning of backflow

A back pressure valve, a spring-loaded injection valve, a

relief valve, a foot valve or a liquid end do not represent

absolutely leak-tight closing elements.

– Use a shut-off valve, a solenoid valve or a vacuum

breaker for this purpose.

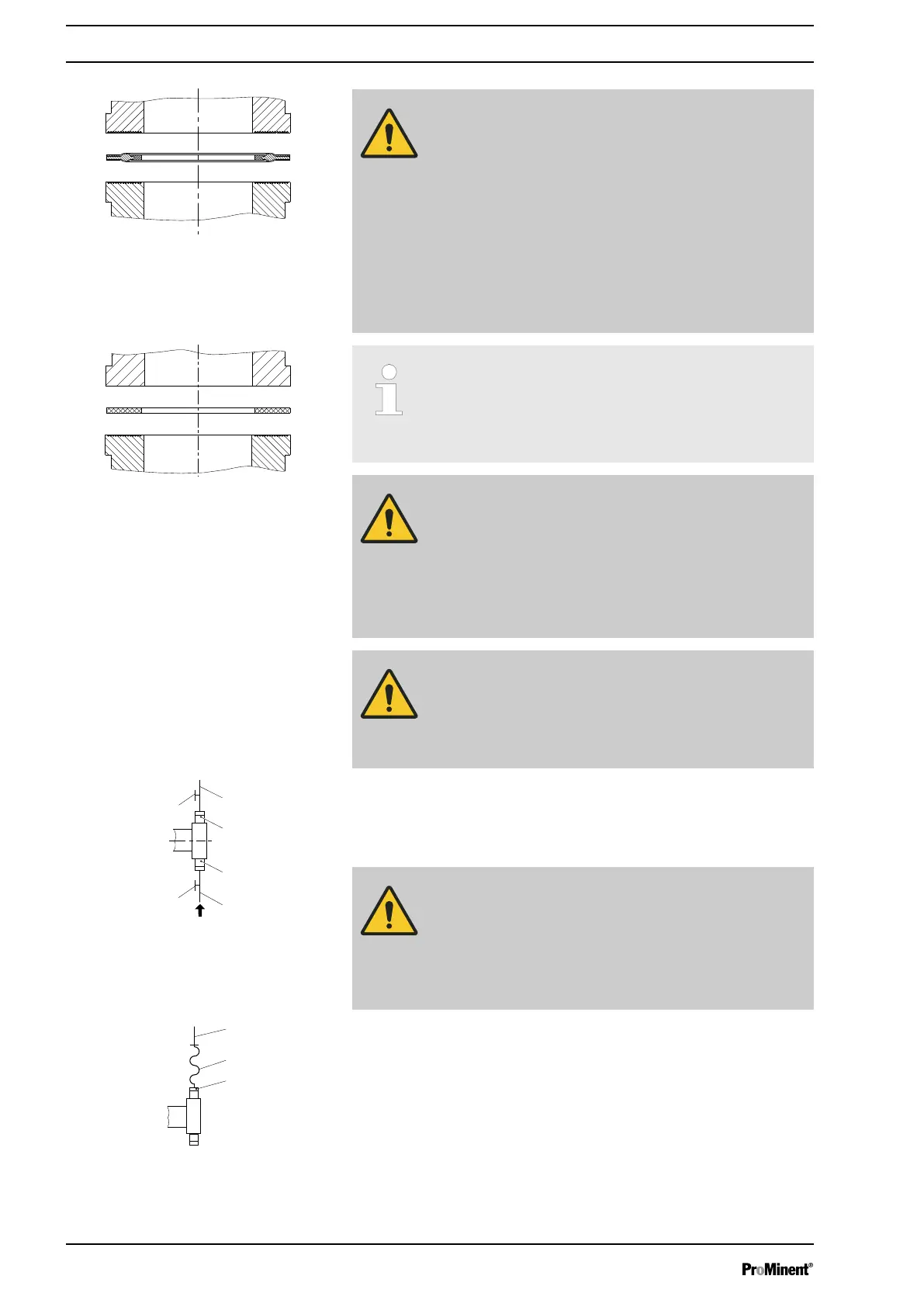

CAUTION!

To check the pressure conditions in the piping system it

is recommended that connecting options for a manom‐

eter are provided close to the suction and pressure con‐

nector.

1 Manometer socket

2 Discharge line (pipe)

3 Discharge valve

4 Suction valve

5 Suction line (pipe)

CAUTION!

Connect the pipelines to the pump so that no residual

forces act on the pump, e.g. due to the offsetting, weight

or expansion of the line.

Only connect steel or stainless steel piping via a flexible

piping section to a plastic liquid end.

1 Steel piping

2 Flexible pipe section

3 Plastic liquid end

Fig. 16: Moulded composite seals with

corrugated insert

Fig. 17: Elastomer flat seal for a smooth

insert

Fig. 18: Manometer connector options

Fig. 19: Steel pipeline at the liquid end

Installation

28

Loading...

Loading...