10

Confirm frame is square on the same plane

and not rolled.

12112

C. INSTALL FRAME (CONTINUED)

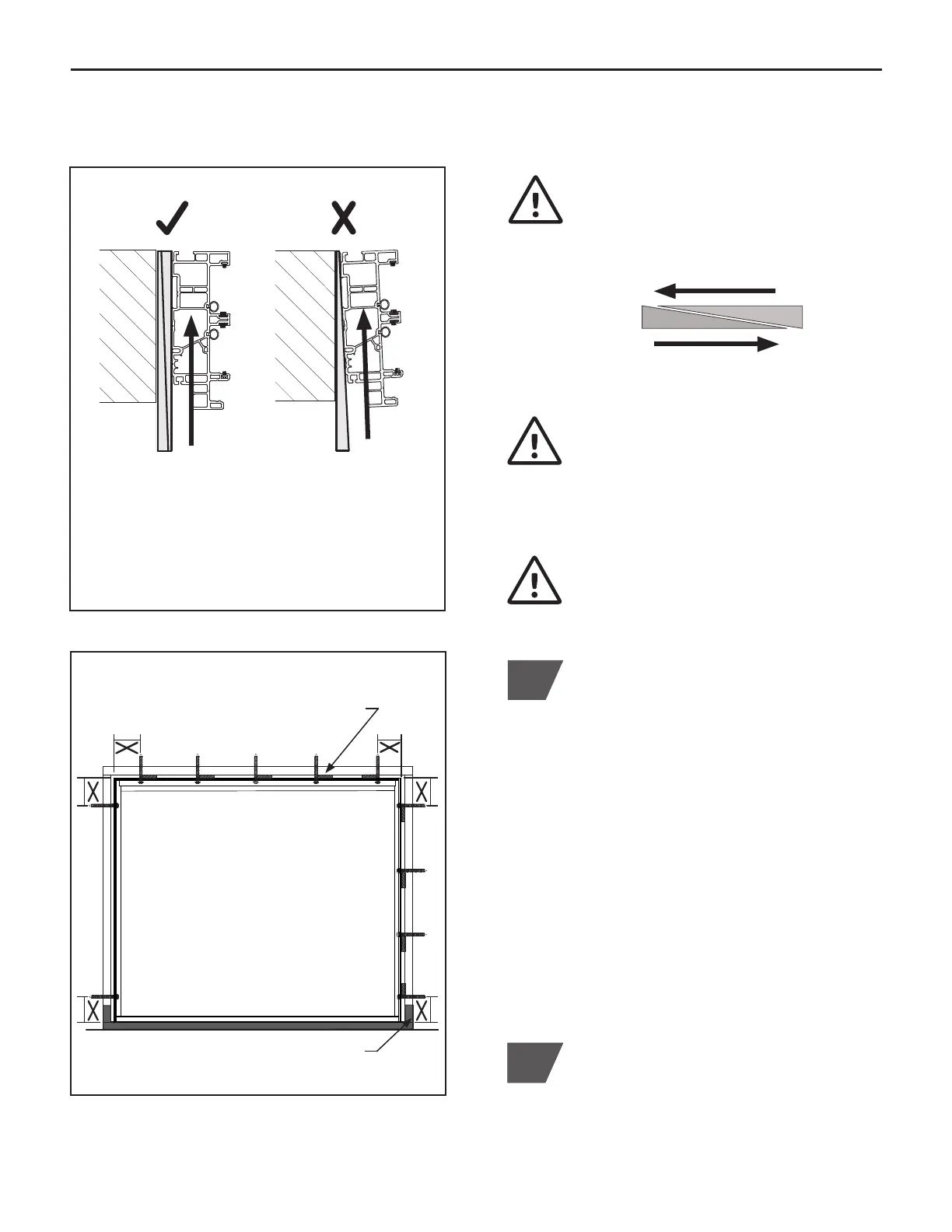

(Figure C.6)

11

Place shims next to each installation screw

location, each jamb side and header. Be

sure top jamb shims are located 4" to 6"

from top of frame and bottom shims are 4"

to 6" from bottom of frame. Be sure header

shims are located 4" to 6" from each corner. If

spacing between side jamb or header shims

is greater than 12" to 18", additional shims

may be needed to maintain margins and

stabilize frame. Use shims to adjust straight

and parallel as needed. (Figure C.6)

NOTE: To allow for vinyl expansion, DO NOT

place shims at top header, bottom sill, or

header corner locations as shown. Shimming

in these locations will cause frame distortion.

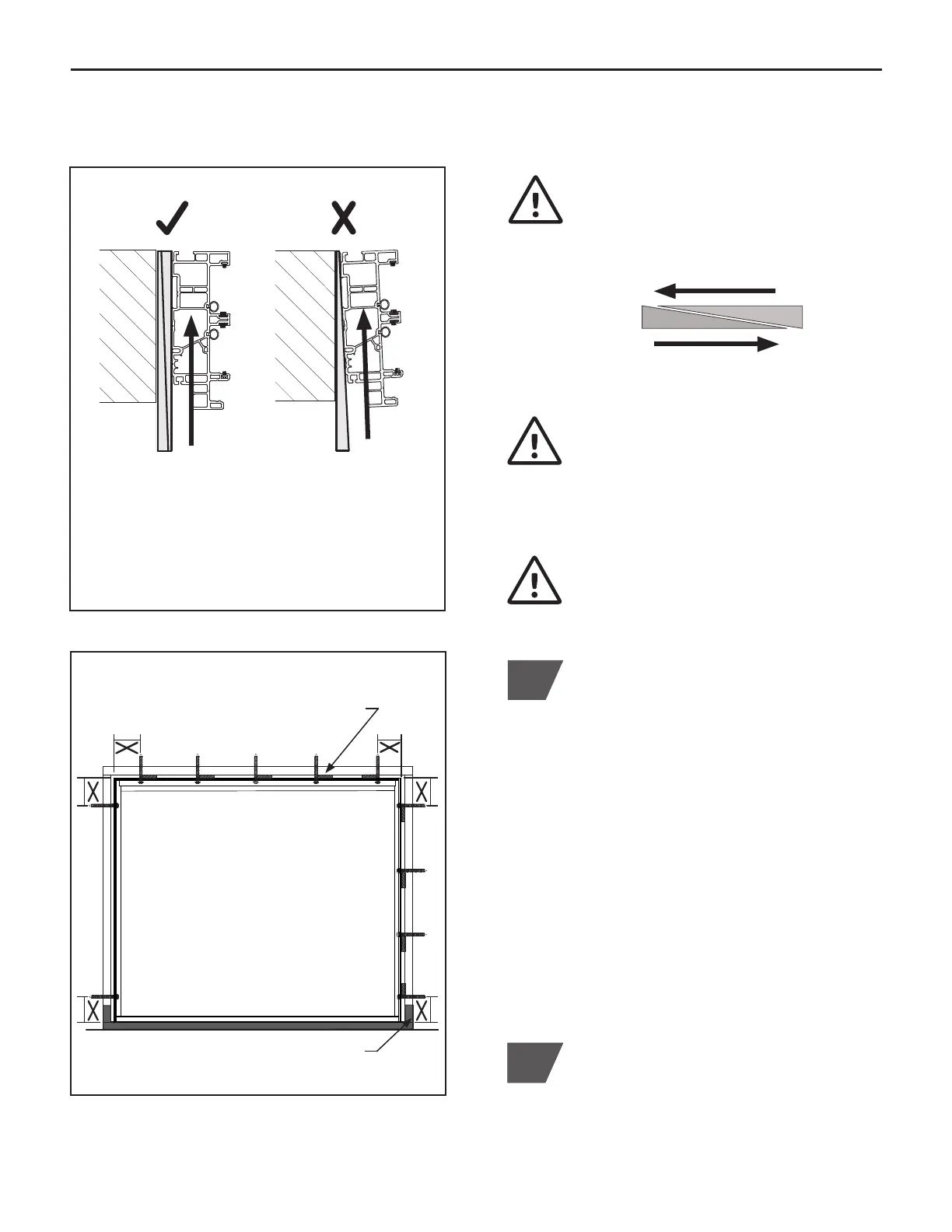

IMPORTANT! CORRECT shimming

application; stack wedge shaped shims

contrasting and plane to plane. See diagram

below. DO NOT use single wedge shims.

This will cause the frame to roll. (Figure C.5)

IMPORTANT! Be careful to NOT over

shim. Improper shimming may roll,

bow, and change margins, jeopardizing

operational performance.

Exterior View

(Figure C.5)

CORRECT

Flat shims or wedge

shims stacked to

create a flat plane will

result straight frame

NOT CORRECT

A wedge shim will

cause frame to roll

resulting in rolled and

bowed frame

SHIMMING APPLICATIONS

Place stacked shims next to each header and

fixed jamb side screw locations

DO NOT place shims at top

and bottom jamb locations, each side

To prevent water infiltration, DO NOT

install screws through sill.

4" to 6" 4" to 6"

Loading...

Loading...