14 pulsar 3

Process set-up - Format (formatting NiCd and NiMH cells)

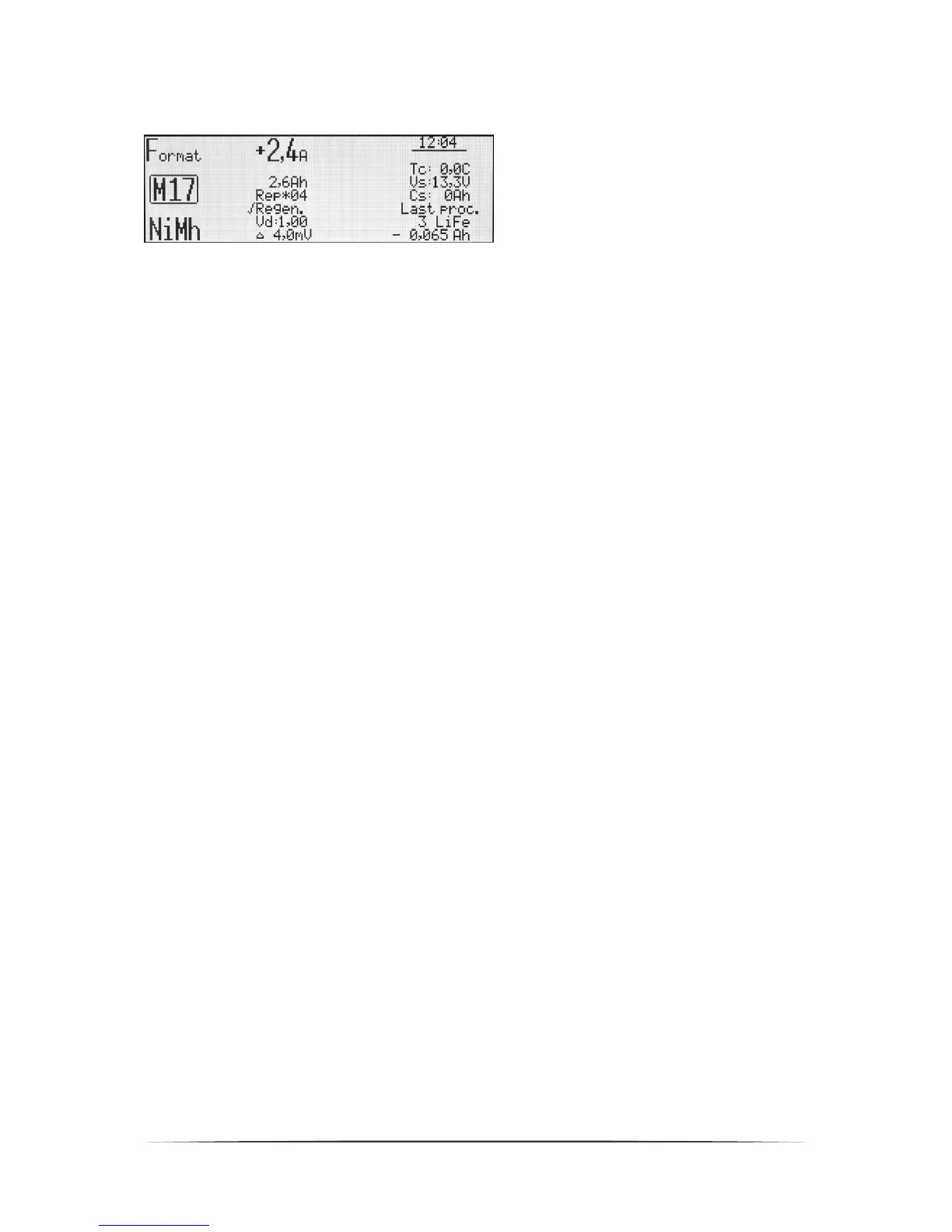

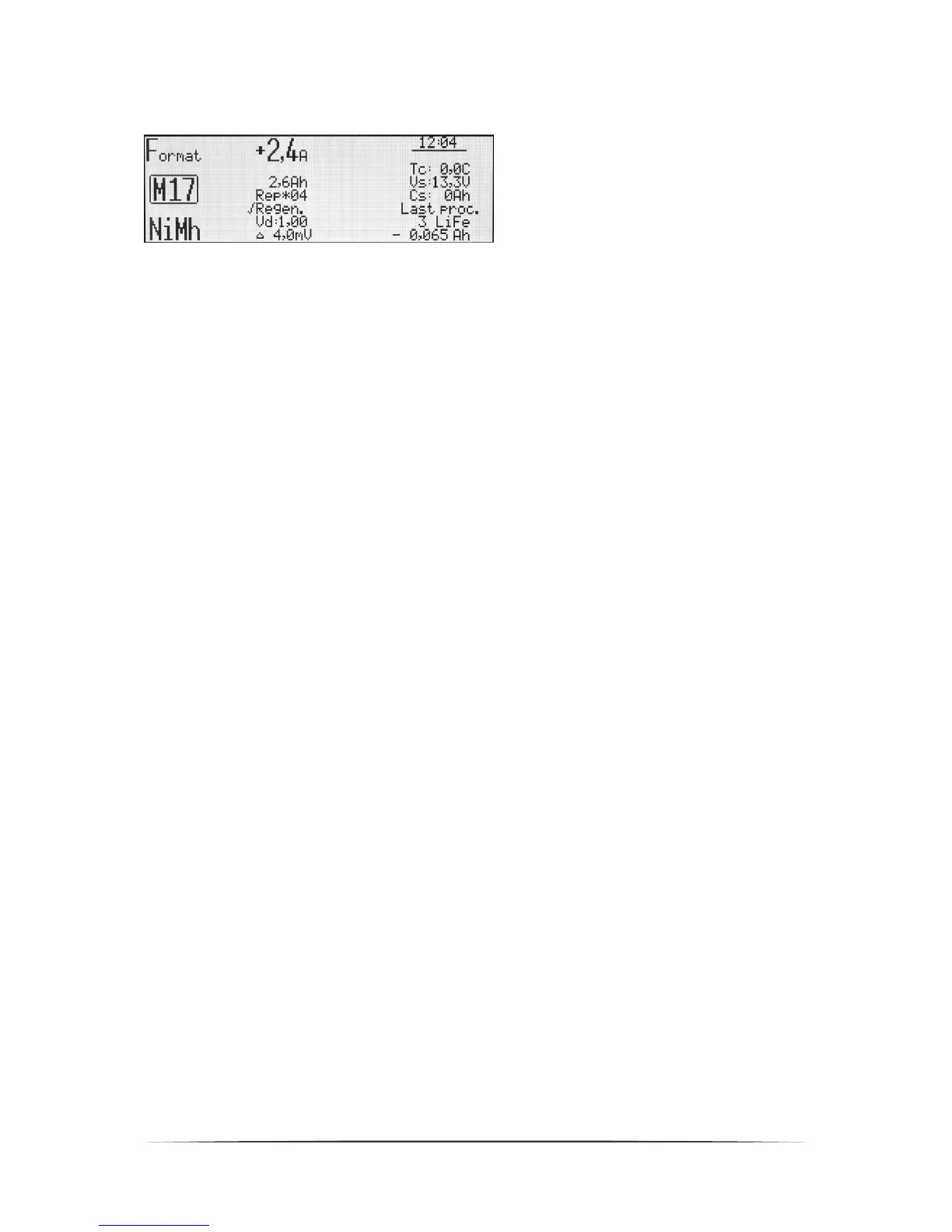

Window description. From top left: formatting is

set; in memory window M 17; NiMh battery type;

2,4A charge and discharge current; 2,6Ah limiter; 4

cycles (Rep*04); regeneration enabled; final

discharge voltage Vd (1,00V); Δ 4,0mV (standard

value)

Formatting NiXX battery packages is conducted through programming the number of charge/discharge cycles.

The discharge is conducted in this program if the “Auto” parameter is enabled. Formatting NiXX cells is

particularly important with new, not yet used packages, whose cells are not yet equalized.

General formatting is conducted with low currents of an estimate value of 1/10 C. „C” represents the charge or

discharge current which is dependent on the battery capacity (in ampere-hour). And so, a battery with 500mAh

capacity a 1C current is equal to 0,5A.

First, choose the appropriate memory window that is to be programmed (from M 1 to M 20). Secondly, enter the

program window by holding the dial, where the “Mode & Accu” option is selected. Here the battery type is set to

NiCd or NiMh and then Format. (formatting),

The process parameters can be changed if necessary. Through holding the dial we enter the program window

where we chose the “Parameters” option, which enables us to set all the parameters important for the process for

a particular battery type.

And so:

-exit- – return to memory window.

Rep*01 – number of formatting cycles from 1 to 99. Please bear in mind that the “Pause” value set in the

setup concerns only the pause time between the processes (e.g. charging – pause – discharging – pause -

…). During formatting a new package, at least 3-4 cycles are recommended.

Regen. – a special means of regenerating cells In the used packages, which have lost some of its capacity

and have a heightened internal resistance. During formatting with regeneration, at least 2-3 cycles are

recommended.

Vd – final discharge voltage settings. If the set value is other than the recommended settings, an

exclamation mark will be displayed (! Vd). For cell types: NiCd 0,60-0,95V/cell.

Δ – „Delta-Peak“ setting, if the set value is other than the suggested one, an exclamation mark is displayed

(! Δ). With NiCd the value may be set from 4 to 25mV and 1-15mV with NiMH.

Setting the formatting current

We can set the limiter value after a press of the Rotary knob we set the desired format current in the memory

window (same current for charging and discharging) and then confirming (press). It is recommended to use the

limiter, especially with new packages which have not yet been formatted. The limiter setting should be a bit higher

than the cell’s capacity (by abort 5-10%). Unnecessary overloading as a result of unequally charge cells, which

makes proper recognition of the Inflex point or Delta Peak, may be prevented in this way.

After all settings meet our requirements we can plug in the battery packages to the charger. Before beginning the

process it is necessary to check if the number of cells in the package matches that indicated by the charger. After

adjusting the number of cells, if necessary, we can start the process by pressing the Rotary knob.

Balancer – operating

A balancer (Equalizer) integrated with the charger Works with a high power (1A balancing current). The balancer

equalizes the cells’ voltage In packages to the lowest one (e.g. for a 16s package – 15 cells can be equalized

simultaneously). Each balancing channel has an individually regulated equalizing current – it depends on the level

of unbalancing. For each battery type a different initial balance current is fitted, which is corrected in the case of a

strong unbalancing (balancing may begin earlier). The higher the cell’s voltage is, the more intensive the

balancing. It is important to mention, that balancing below a certain voltage limit is not only not recommended but

even harmful. That is why it is recommended to balance during charging. The only exception is when the

package is prepared for longer storage (Store). For measuring the voltage by using the balancer port, it is also

possible to connect a single cell. This is important for the "Test" function (Ri measurement).

Loading...

Loading...