PuraTech

®

Owner’s Manual 12/11/2013 23

Assembly and Parts, Cont.

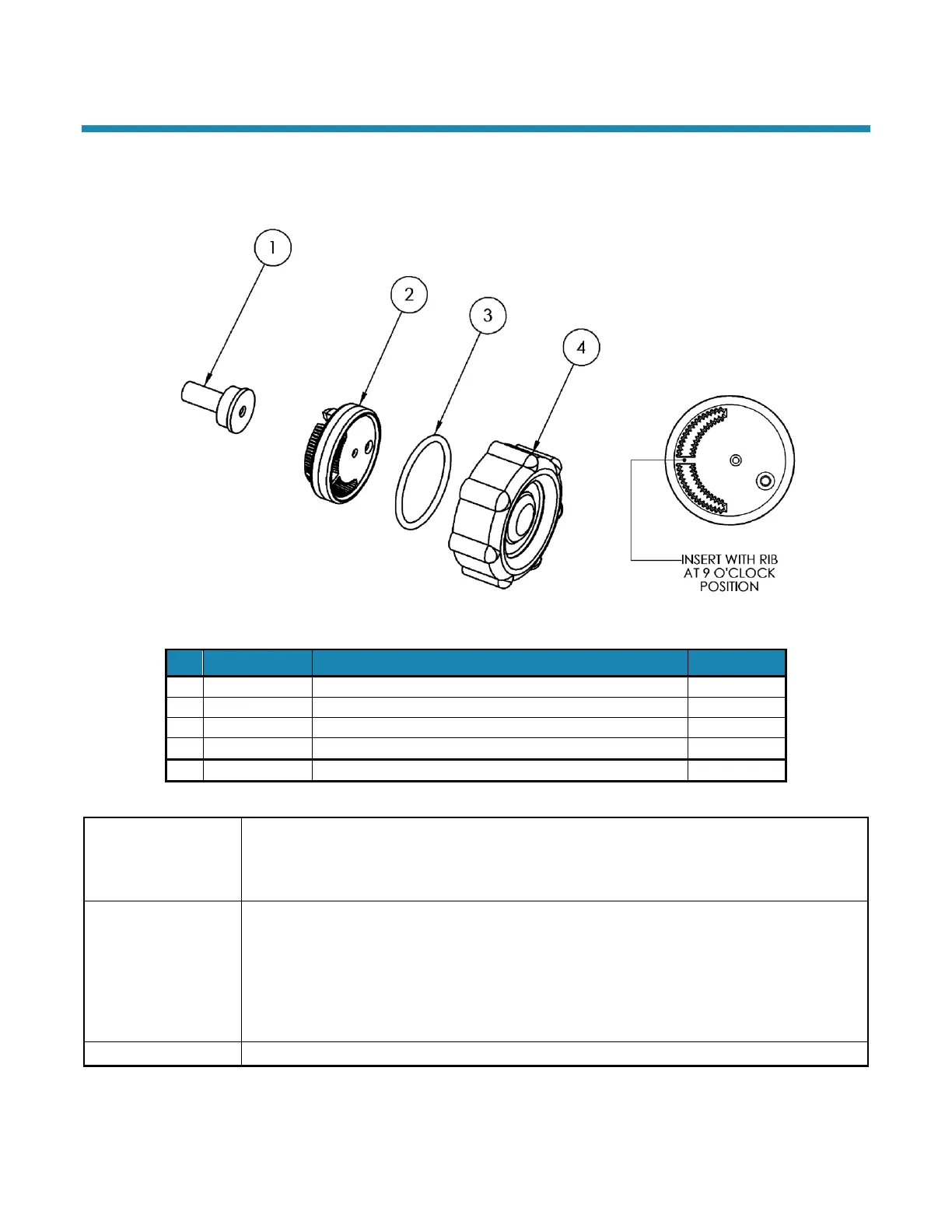

Injector Assembly

Figure 11: Injector Assembly

Injector Nozzle with Over-Mold Gasket

Throat

In conjunction with the Injector Nozzle it creates the vacuum that draws the brine solution from the

brine tank. The center hole should be clear of debris, round, and undamaged. The Throat should

be pressed flush into the opening in the valve. If the Throat is removed, it must be replaced with a

Nozzle with

Over-Mold Gasket

Together with the Throat creates the vacuum that draws the brine solution from the Brine Tank.

The small hole in the Injector Nozzle is the one that creates the “injection-stream” that enters the

Throat. It is important that this hole is round, undamaged, and clear of debris. If this hole becomes

“clogged,” do not use anything (such as metal objects) to clear this opening. Damage may occur.

Use a clean cloth and flush with water. If necessary, a wooden toothpick may be used. When

assembling to the Valve, the Nozzle hole should line up with the Throat. Flush screen with water

to clean. The over-mold gasket seals between the Injector Nozzle and the Injector Cap.

Holds the injector assembly together and seals the assembly to the Main Control Valve.

Loading...

Loading...