PuraTech

®

Owner’s Manual 12/11/2013 25

Assembly and Parts, Cont.

Drive End Cap Assembly Cont.

The Motor is held in place by two 1/2-inch thread-cutting screws. The screws should be “snug.”

The brass pinion gear on the Motor should engage the plastic Drive Gear. The wires should be

securely fastened to the Controller.

The Drive Gear is assembled to the Slide Cam by means of a “keyed” opening, which transfers

the “torque” generated by the Motor to the rest of the drive system. If the drive system becomes

jammed, this opening can become “rounded” causing the gear to turn, but not the Piston Slide

Cam. If this occurs, clear the jam and replace the Drive Gear and Piston Slide Cam.

93219 Piston Slide

Cam Cover

The cover secures the Piston Slide Cam in place and acts as a bushing for the Cam Shaft.

Cam

This is the “heart” of the drive system. A threaded stainless steel shaft runs through the main drive

axle. The Drive Gear is attached at the short end and the Magnet Disk at the other end. The Slide

Cam is assembled inside of the Piston Slide. This Cam Shaft should turn freely before the Motor

Seals the two openings on the Main Control Valve. The larger diameter opening is sealed with an

O-Ring used as an axial or “face” seal. The O-Ring sits in a groove in the End Cap. This groove

must be free of defects such as pits or scratches and also free of debris. The smaller diameter

seal is accomplished with an O-Ring used as a radial seal. The O-Ring should be placed on the

male boss on the End Cap. When assembling the End Cap to the Main Control Valve, care should

be taken to make sure the small O-Ring is aligned with the opening in the Main Control Valve and

that the large O-Ring stays in the groove in the End Cap. If misaligned, the O-Rings can become

The Slide should move freely inside the End Cap Housing.

Assembly

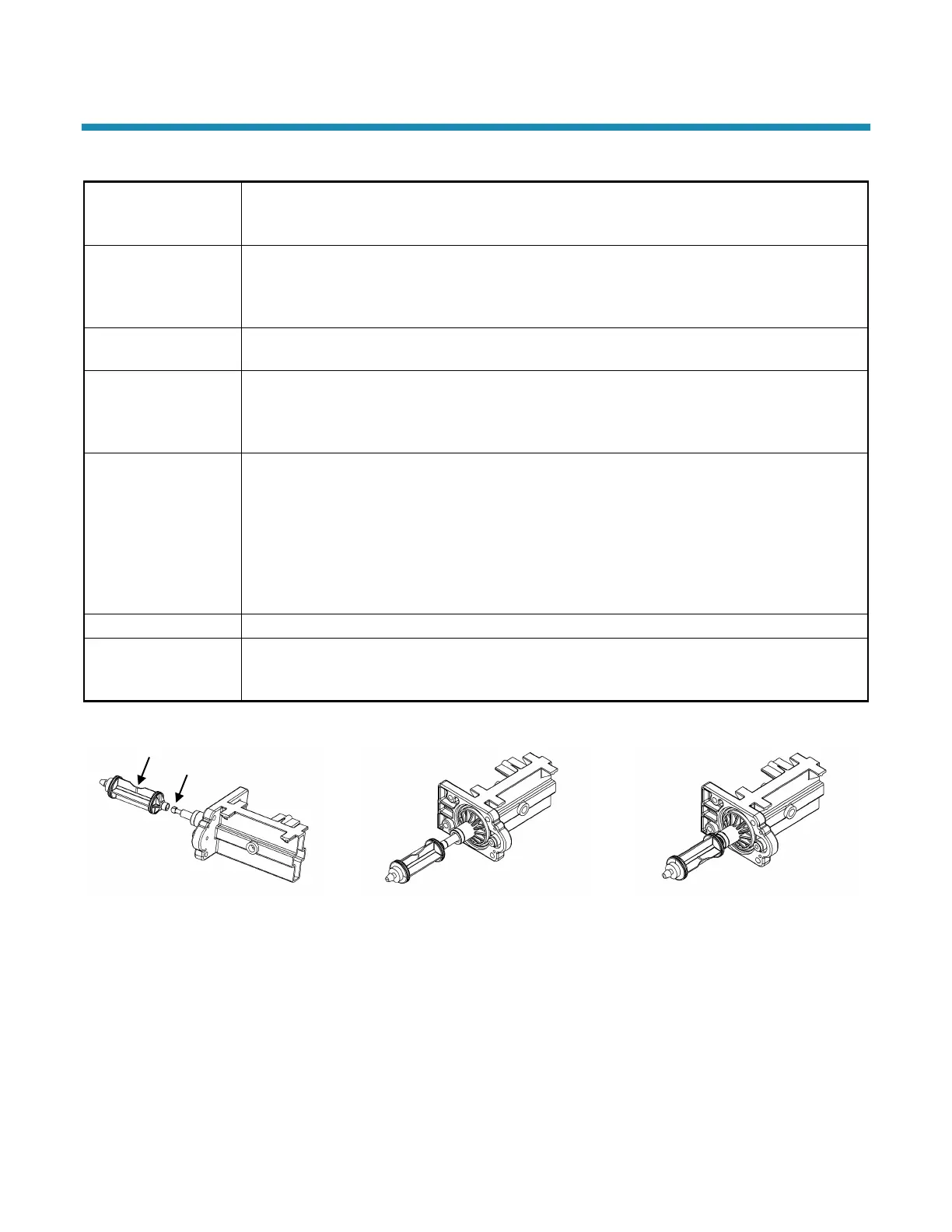

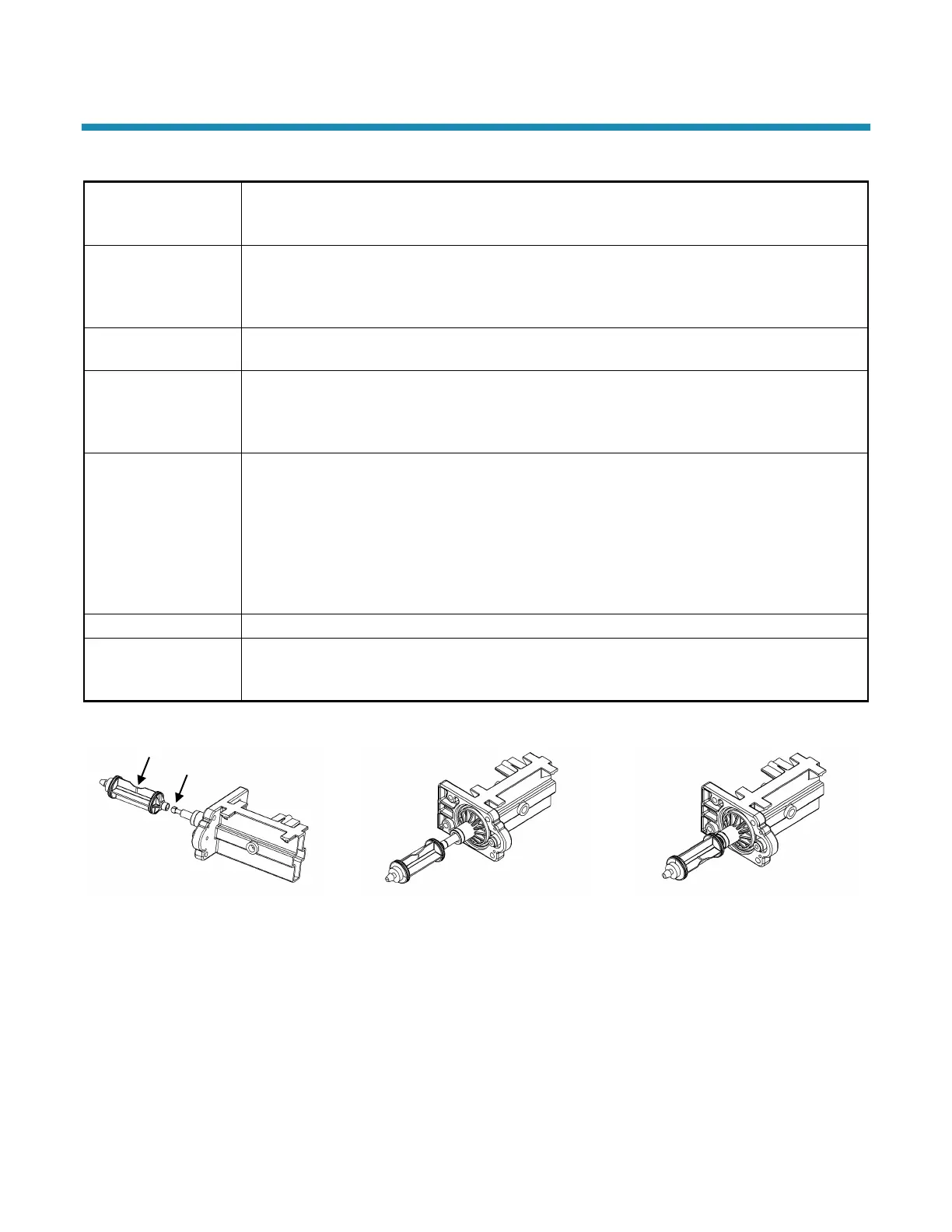

The Drive Piston attaches to the Piston Slide by placing the “slot” of the Piston onto the matching

flat of the Slide. To remove Piston, rotate Piston 90° counterclockwise. To replace Piston, rotate

90° clockwise until you hear an audible “click.” See reference drawings below.

Position Piston Assembly (53322) Vertical

Slide Piston Assembly Onto Piston Slide.

Push Toward End Cap to Stop.

Rotate The Piston Assembly 90 Degrees

Clockwise Until You Hear An Audible Click

As It Snaps Into Place

Align Flats

Loading...

Loading...