14

1145094-W2-D

Rada V12 Exposed Shower Valve

Rear Entry Supplies (rising or falling concealed pipework)

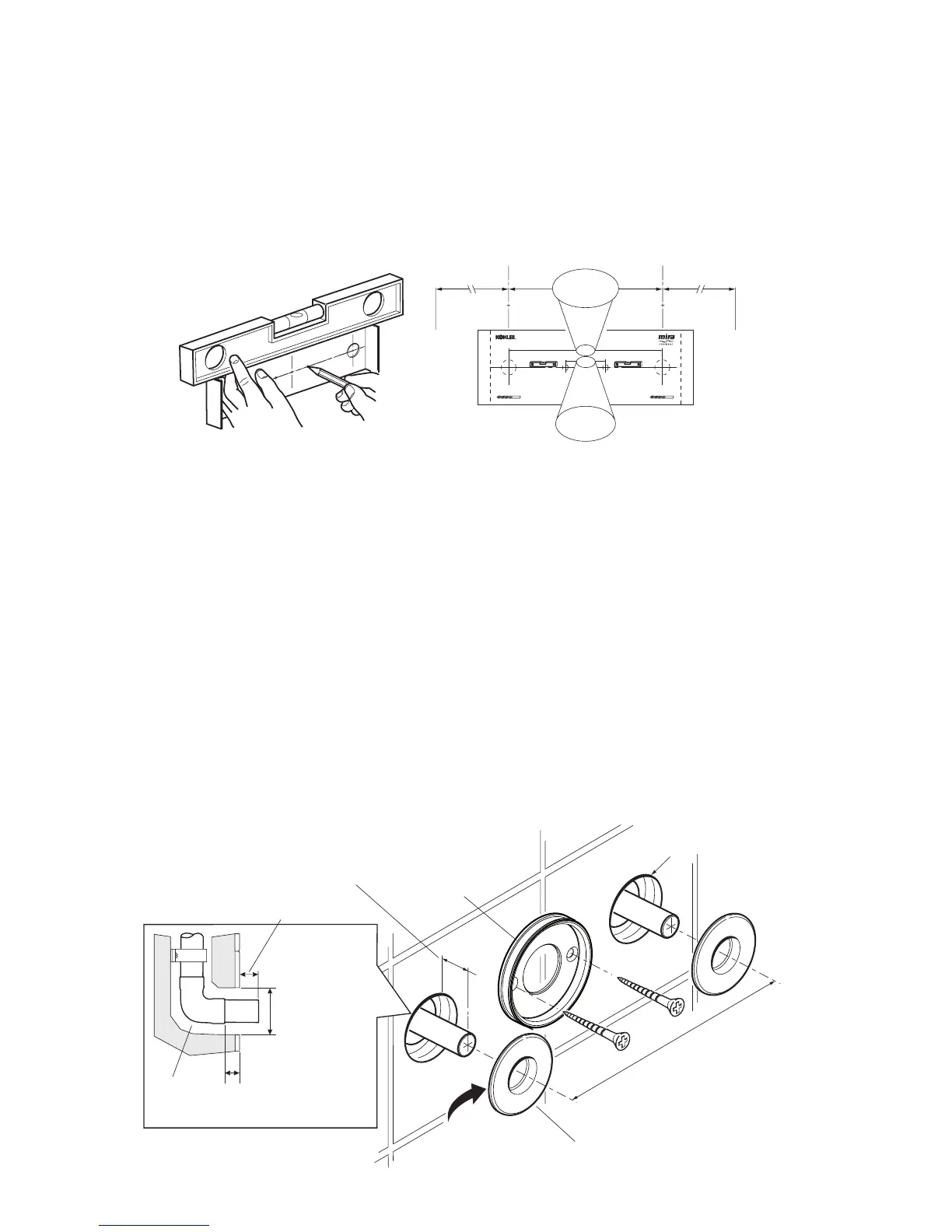

1. Use the Installation Template to mark the positions of the holes for the backplate

and the pipe centres (Not applicable for the V12 130 Centres Model).

Note! Allow a minimum of 150 mm either side of the mixer, to allow access to

the hot and cold Inlet lters for servicing.

40 mm

153 mm

Shower Control

Backplate Fixing Points

(Ø6 mm)

Bend tabs inwards

Use as a support for the spirit level

Bend tabs inwards

Use as a support for the spirit level

Hot Supply Inlet

(Ø15 mm)

Make sure that supply pipes are thoroughly flushed through

before connection to the shower control

Cold Supply Inlet

(Ø15 mm)

153 mm

150 mm

40 mm

150 mm

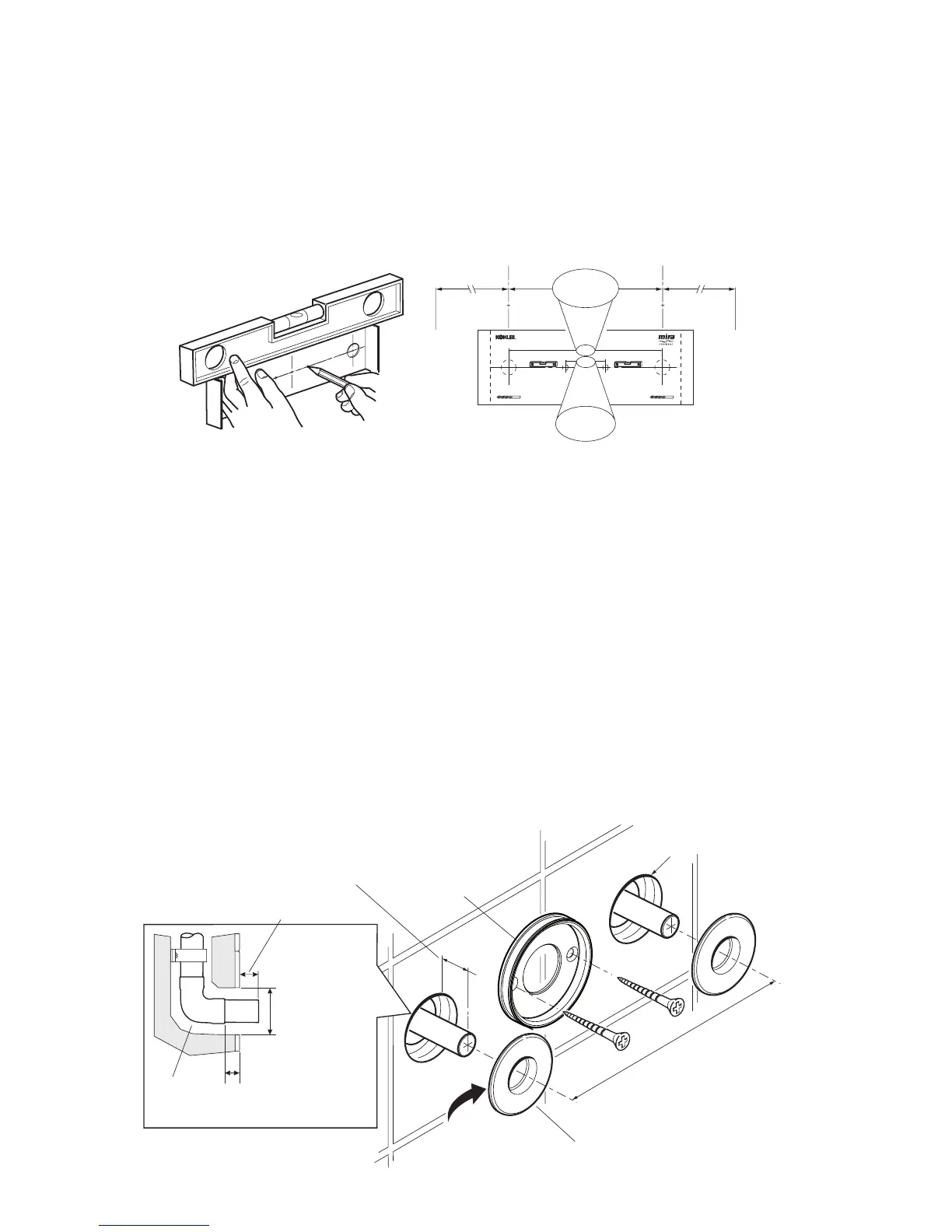

Ø32 mm x 10 mm depth

for Concealing Plates

153 mm

Apply Silicone

Sealant

Backplate

Concealing Plates

10 mm minimum

between Elbow

and nished wall

surface

32 mm

18 mm from

nished wall

surface

Elbow

2. For solid walls drill the holes for the backplate with a 6 mm drill and insert the

wall plugs (supplied). For other types of wall structure alternative xings may

be required (not supplied).

3. Drill the holes for the supply pipes at 153 mm centres.

4. Recess the wall to allow for the pipe concealing plates, Ø 32 mm x 10 mm

deep.

Note! Depth must be sufcient to prevent the concealing plates fouling on the

plumbing elbows.

5. Fit the supply pipework (Hot - Left, Cold - Right). The pipework must project

18 mm from the nished wall surface at 153 mm centres (use the Installation

Template as a guide).

Note! If the connections are reversed, then turn the valve through 180° to

ensure that the hot supply is connected to the hot inlet and reverse the outlet

fittings as necessary, refer to section: ‘Reversed Inlet Supplies’

Hot

Cold

Loading...

Loading...