User and maintenance manual for stoves with RDS technology

Pag.31

01/02/2016

FLOWMETER (only

if the RDS system is

provided)

PHASE SCREW

ALARM

TRIAC SCREW

ALARM

NO FLOW (only if

the RDS system is

provided)

• The device is disconnected or defective

•

Please contact the local Technical Assistance Centre

• The gear motor is not correctly connected

•

Please contact the local Technical Assistance Centre

•The device in the motherboard which commands the feeding screw

is defective

•

Please contact the local Technical Assistance Centre

- The ow meter does not measure inlet air ow

- Check if the ash pan and door are closed correctly and check if the

air inlet pipe is obstructed.

- If the problem persists, contact the Support Service

9. Description of alarms

WARNING

REASON SOLUTION

NO PELLET

• The pellet hopper is empty • Check whether there are pellets in the hopper

• The gearmotor does not load pellets.

• Empty the hopper to check that no objects have fallen inside

which could prevent the correct functioning of the screw

• No pellet loading

• Regulate the pellet setting

• If the problem continues, contact the area Technical

Assistance Centre.

BLACK - OUT

• No electricity supply during working phase

• Press the o button and repeat switching on the stove

•

If the problem continues, contact the area Technical Assistance Centre.

NO IGNITION

ALARM

• The pellet hopper is empty.

• Check if there are pellets inside the hopper.

• Setting of pellets and of intake during ignition phase

insucient.

• Contact local Technical Assistance Centre.

•

The igniter is defective of not in correct position.

• Contact local Technical Assistance Centre.

ALARM LOW

FLAME

• The pellet hopper is empty. • Ceckis pellet is in the hopper

• Bad setting of pellet and air for the ignition phase

• Contact local Technical Assistance Centre

ALARM FAN

RPM

• The speed of flue fan is lower more then 15% of set value.

• Contact local Technical Assistance Centre

ALARM FAN

BROKEN

• Flue fan encoder is not working or not correctly connected

• Contact local Technical Assistance Centre.

• No power supply to ue fan

• Contact local Technical Assistance Centre.

• The flue fan is blocked • Contact local Technical Assistance Centre.

DEPRESSION

ALARM

• The combustion chamber is dirty

• Follow the cleaning operations of the stove in the booklet

• The chimney is blocked • Check that the chimney is clear and clean

• The pressure switch is malfunctioning

• Please contact local Technical Assistance Centre

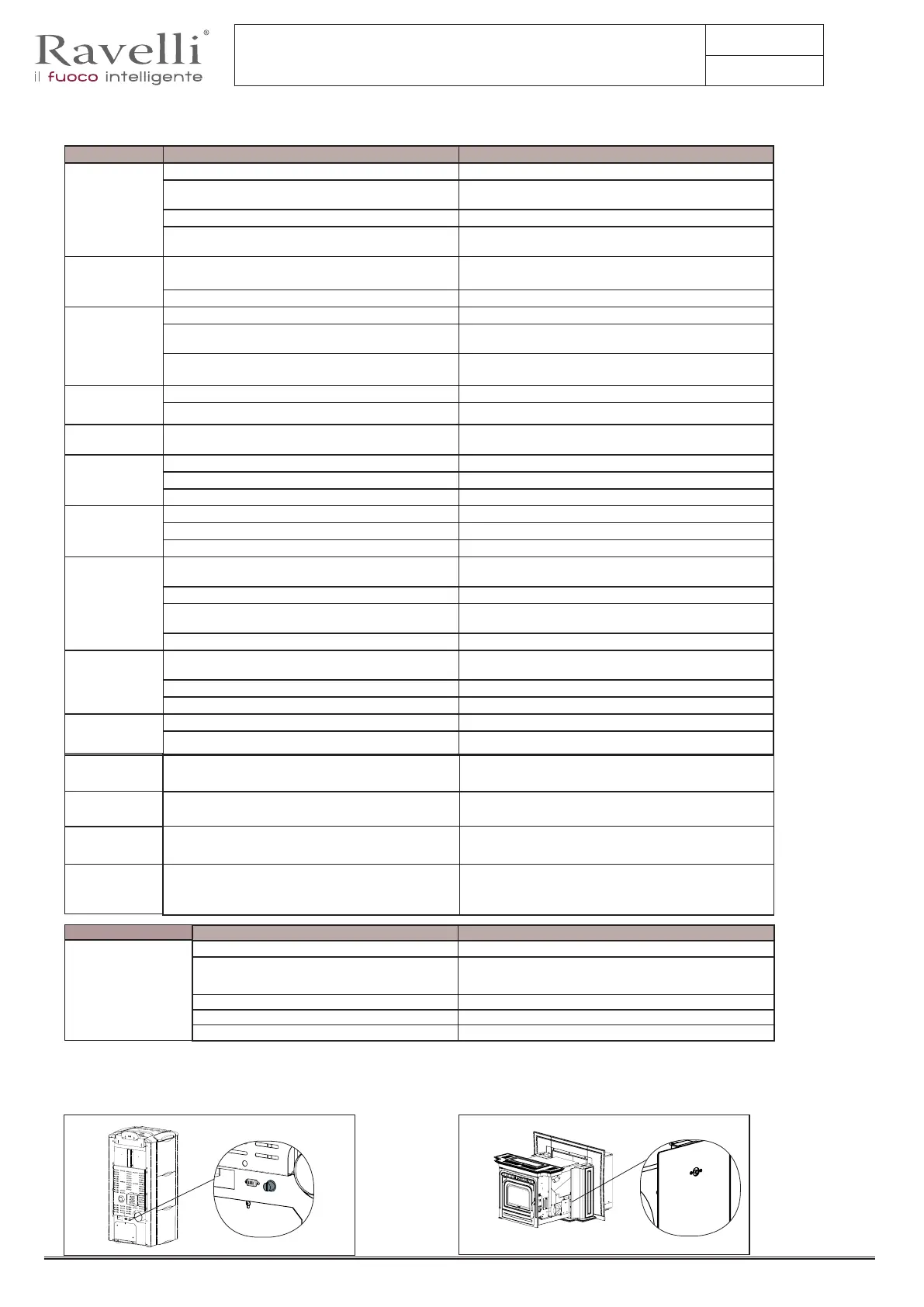

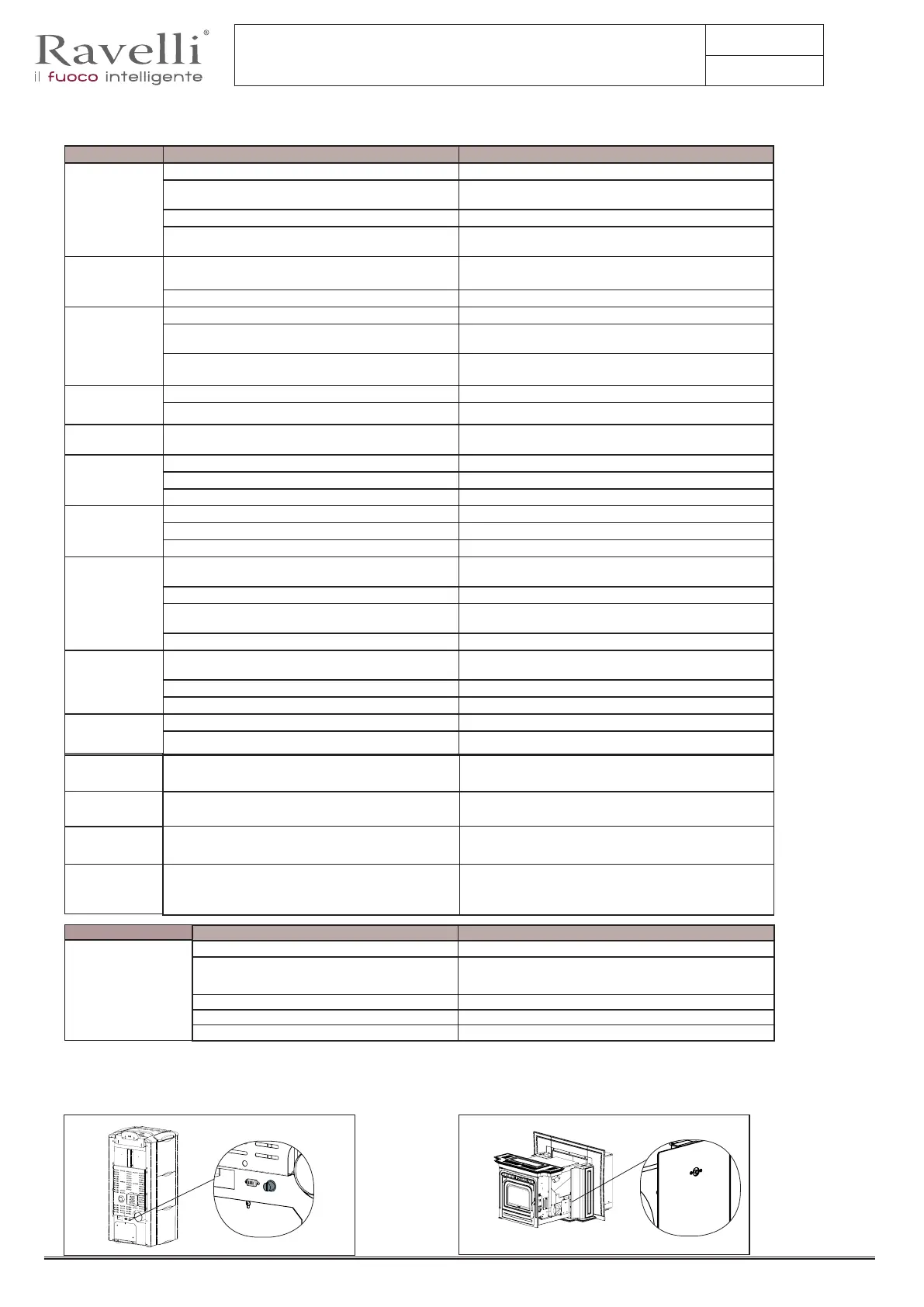

THERMAL

ALARM WITH

RESET

• The thermostat with manual reset has intervened • Reset the thermostat pressing the button on the back

of the stove (see Pic. below).

• The air fan is defective

• Please contact local Technical Assistance Centre.

• Combustion in the re pot is not

optimal

• Switch o the stove, clean the re pot and regulate

combustion with the setting of the pellets.

•

If the problem continues, contact the area Technical Assistance Centre.

HOT SMOKE

ALARM

• Combustion in the re pot is not

optimal

• Switch o the stove, clean the re pot and regulate

combustion with the setting of the pellets.

• The air fan is defective

• Contact local Technical Assistance Centre.

•

If the problem continues, contact the area Technical Assistance Centre.

SMOKE SENSOR

ALARM

The smoke sensor is malfunctioning

• Please contact the local Technical Assistance Centre

The smoke sensor has been disconnected from the board

• Please contact the local Technical Assistance Centre

REASON

SOLUTION

• The door and the ash box are not closed correctly

•Make sure they are properly closed.

• Poor combustion in grate.

•

Switch o the stove, clean the re pot and check the cleanliness of

thesupport bench, clean the tube bundle by activating the turbolators.

andadjust the combustion through Pellet/Air settings.

•

Presence of foreign body in air intake tube. • Check for any foreign body and remove it

• The air ow meter may be dirty.

• Clean the flow meter with the stove in “Switched off” state

•

Contact the Support Service

SIGNALLING

Do CLEANING Fire pot

(only if the RDS system is

provided)

1 - By pressing the button OK on the display. the alarm can be reset.

3 - Try and repeat lighting after the cooling phase.

2 - Unscrew the protection cap and press

the button to reset the thermostat alarm.

THERMAL ALARM WITH RESET

Loading...

Loading...