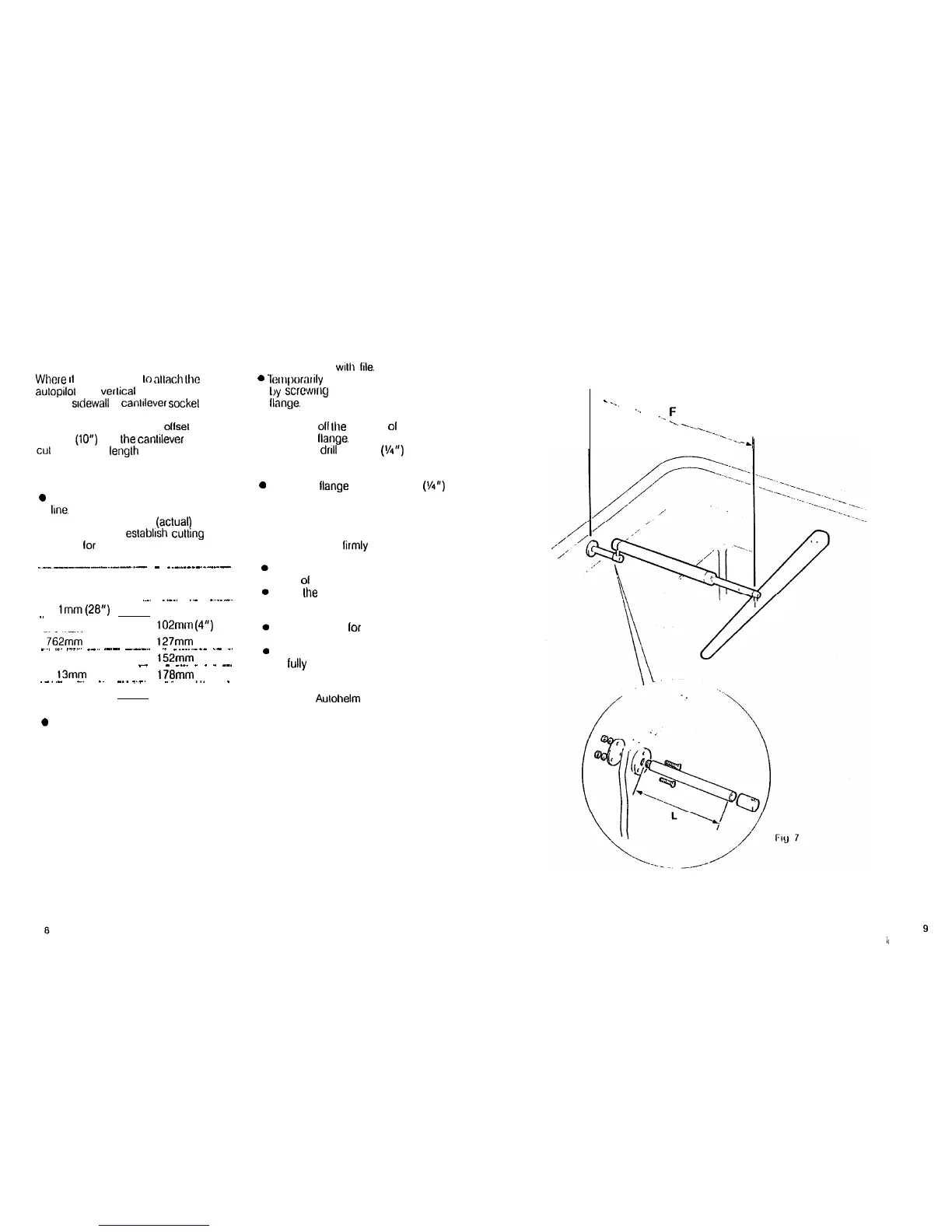

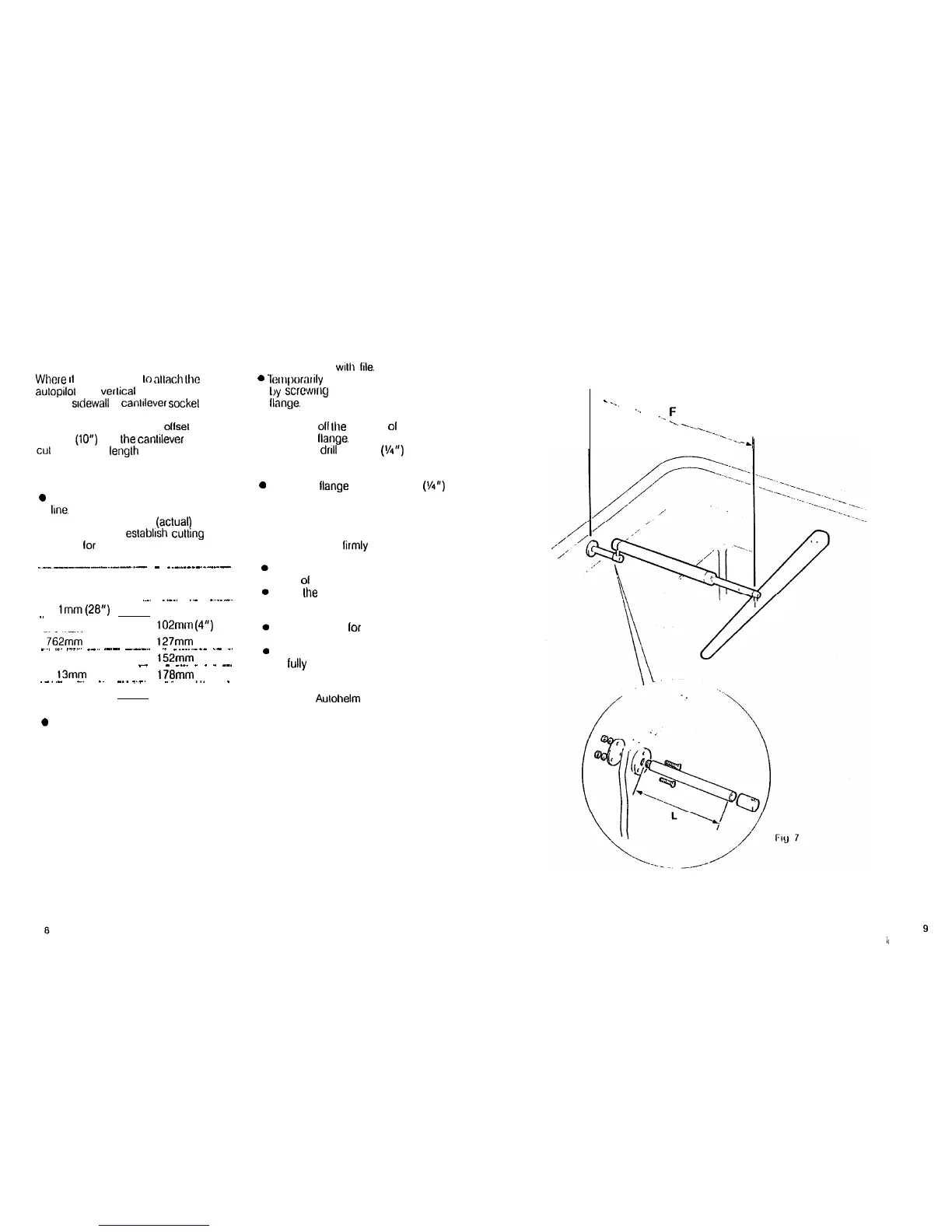

CANTILEVER MOUNTING (Fig.7)

Where

II

is ncccessary

lo

nllach Ihe

aulopilol

lo a

verlical

lace such as the

cockpit

srdewall

a

canlrlever

sockel

assembly is used.

The maximum exlension ollsel is

254mm

(10”)

and Ihe canlilever can be

GUI

IO the exact lenglh necessary during

mounting.

installation

0 Clamp the tiller on the yachl’s cenlre

line.

l

Measure dimension

F

(aclual)

l

Refer lo table lo eslablrsh

cutling

length lor cantilever rod.

_______._____

-

_.-.._-_-._-_--

Dimension F

Cut Length L

686mm (27”) I

51 mm (2”)

.__

.._..

._

_.._~

71

lmm(28”)

75mm (3”)

-.

737mm (29”)

102mrn

(4”)

762mm (30”) 127mm (5”)

_~.

._.

.-__.

_-.

.-.-.

---..

.-

-----..---

.-

-.

787mm (3 1”)

152mm (6”)

_

-

_._.

_

_

_

--.

8 13mm (32”)

178mm (7”)

.-..-

_.

_~

-.. _-.

..-

. .

..-

---

-

838mm (33”) 203mm (8”)

0

Cut cantilever rod to length

L

using a

hacksaw.

Measure

from threaded end.

l

Remove burrs

with

He.

0

Tr?rriporarily

assemble the cantilever

by

scrcwrrlg

the rod into the mounting

Ilange.

l

Ensure lhe drive unit is

horizontal

and mark oil

Ihe

location

ol

the

mounting

Ilange.

l Mark and

drill

3 x 6mm

(V4”)

clearance holes (ignore the two inner

holes).

0 Mount the llange using 3 x 6mm

(l/4”)

diameter bolts wilh nuts and washers.

Be sure to install the backing plate

correctly. Bed the flange on a thin coal

of silicone sealant.

l

Screw the rod

lirmly

into place using a

tommy bar.

Roughen the end of the rod and the

inside

01

the cap to provide a key.

Apply

Ihe

two part epoxy adhesive

provided to the rod end and cap and

place the cap over the rod end.

Ensure the hole lor the drive unit

mounting pin is lacing up.

Allow the epoxy adhesive 30 minutes

to

lully

harden before applying any

load.

When the Autohelm is not in use the

complete rod assembly may be

unscrewed, leaving the cockpit

unobstructed.

_

-_.

.._

._

F

--..

---_

.--..

.-__

-,

9

;/

Loading...

Loading...