Version Number: ARC145-20210106A1

Part 7:Trouble Shooting

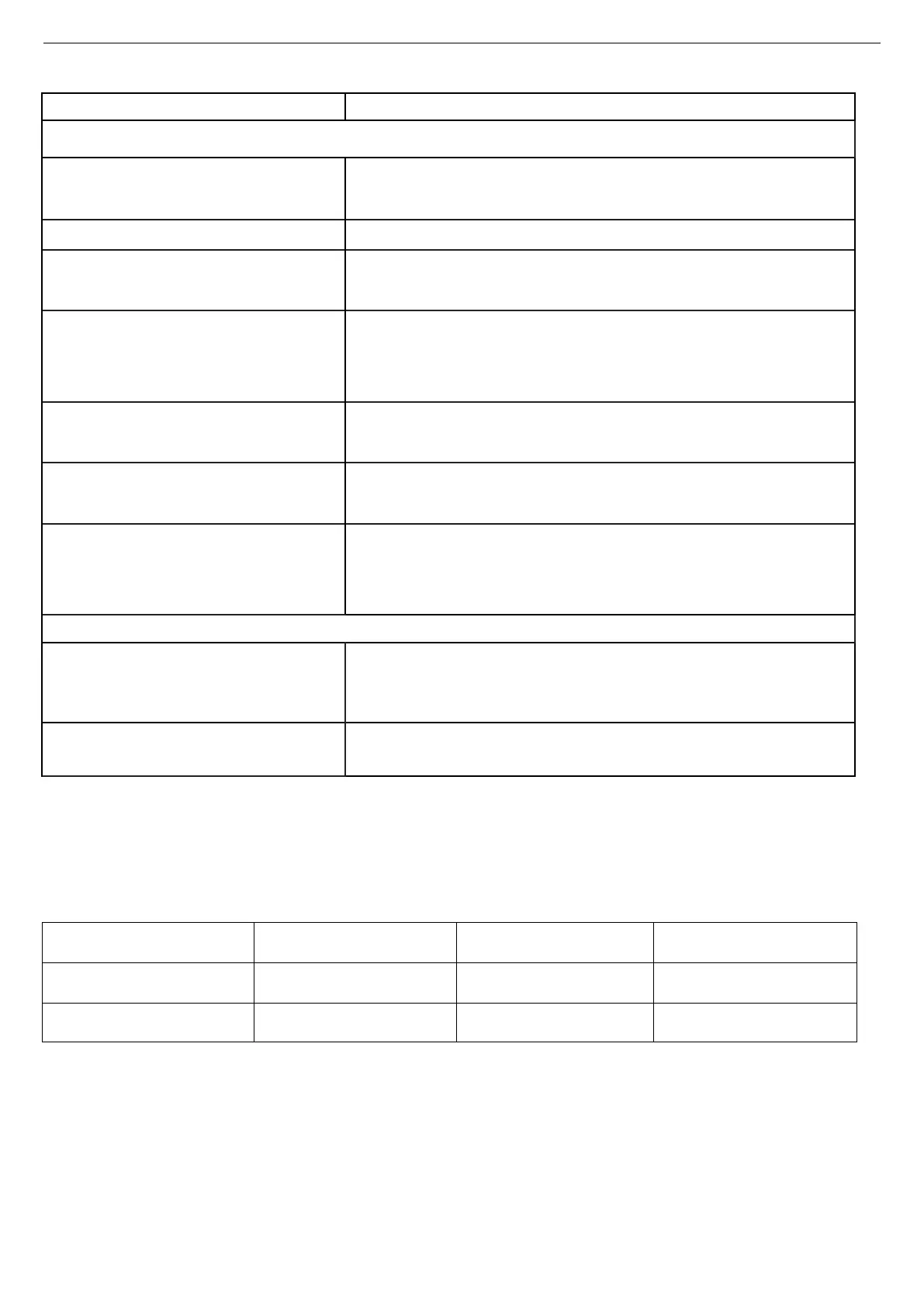

PROBLEMS IN STICK WELDING

1. Fast movement of the electrode away from piece.

1. Poor cleanliness or distribution of the Welding passes.

2. Improper movement of the electrode.

1. High progression speed.

2. Welding current too low.

1. Humidity in electrode.

3. Hydrogen in weld (present on electrode coating).

Machine fails to come on

(Power LED off)

2. Faulty supply plug or cable.

3. Internal fuse tripped. Allow time to Auto reset.

Thermal overload (Thermal LED on)

1. Unit has been operated beyond its capacity rating.

2. Airflow through machine is restrict- ed or fan has failed.

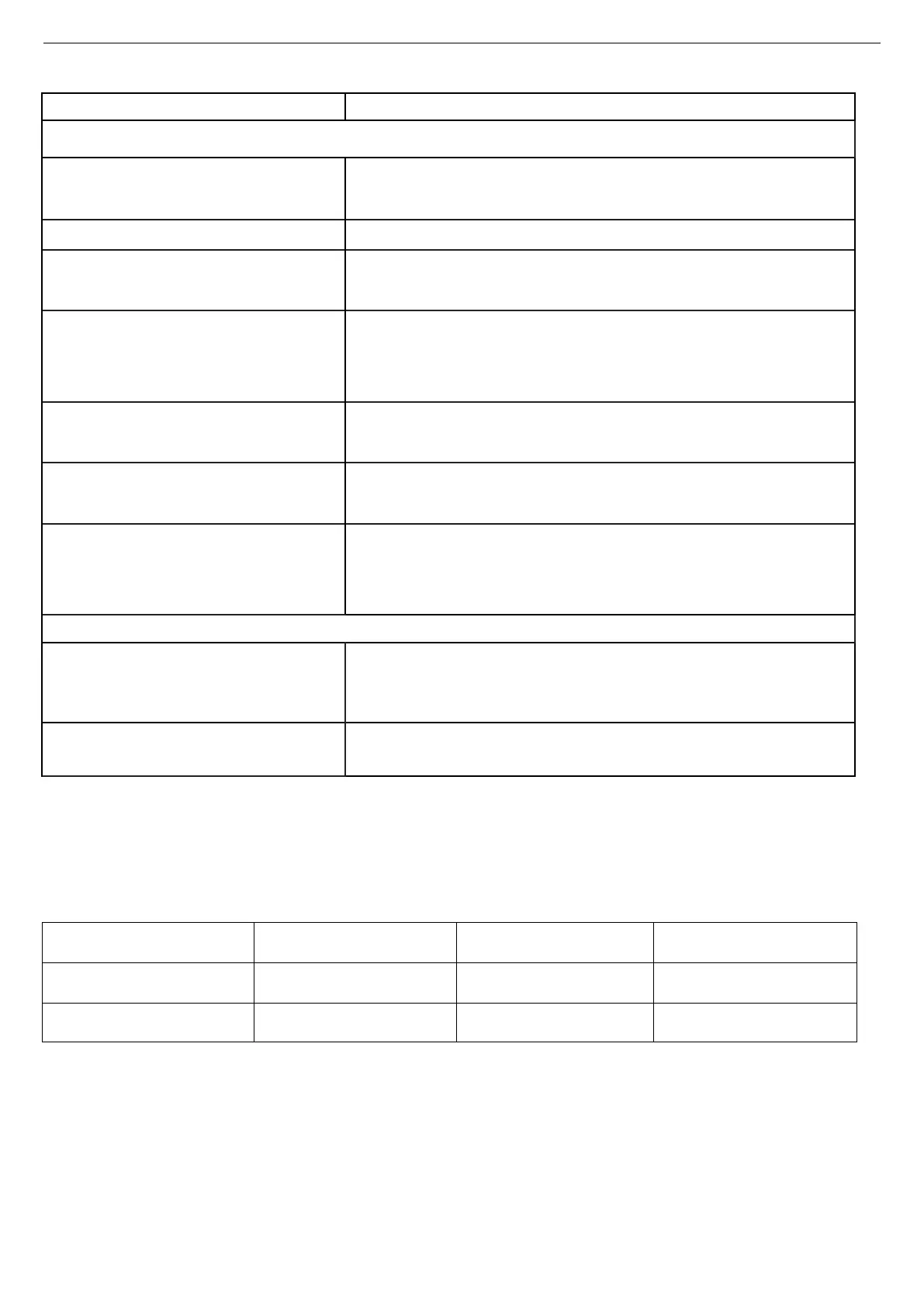

Part 8: Welding parameter settings

If you are interested in translating professional local languages, please contact us at

service@mirthtek.com, we can pay for it.

Loading...

Loading...