— English Fillcontrol Plus — 06.07.2016 - Rev. B

6.3 Execution

Damage due to improper installation

Additional device stresses may arise due to the connection of pipes or system equipment.

• Ensure that pipes are connected from the device to the system without stresses being induced.

• If necessary, provide support structures for the pipes or equipment.

Note!

Starting up of the pump causes vibration in the device. This transfers loud noises into the system pipes.

Connect the pipes to the device using flexible connections.

In systems with a diaphragm expansion tank, the device must be installed in the vicinity of the tank. To ensure that the required filling

pressure for water make-up is recorded by the pressure transducer in the device. The filling pressure depends on the minimum operating

pressure of the facility system. For calculating the minimum operating pressure,see chapter 7.2 "Determining the P

0

minimum operating

pressure for the controller" on page 24 .

Proceed as follows for the installation:

1. Position the device.

2. Create the water-side connections of the device to the system.

– Use connections with the same dimensions at the device for all lines.

3. If required, create the interfaces according to the terminal plan.

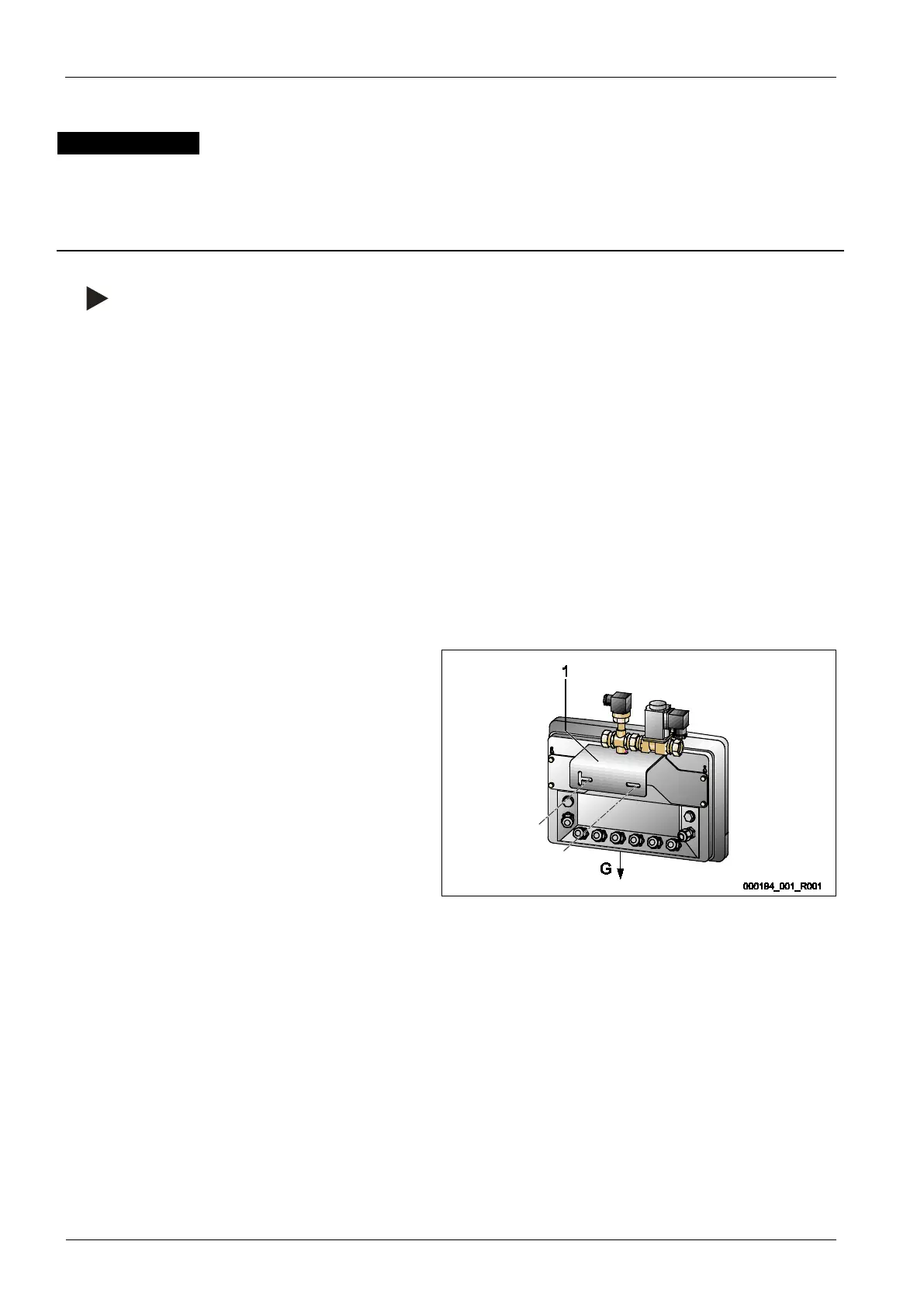

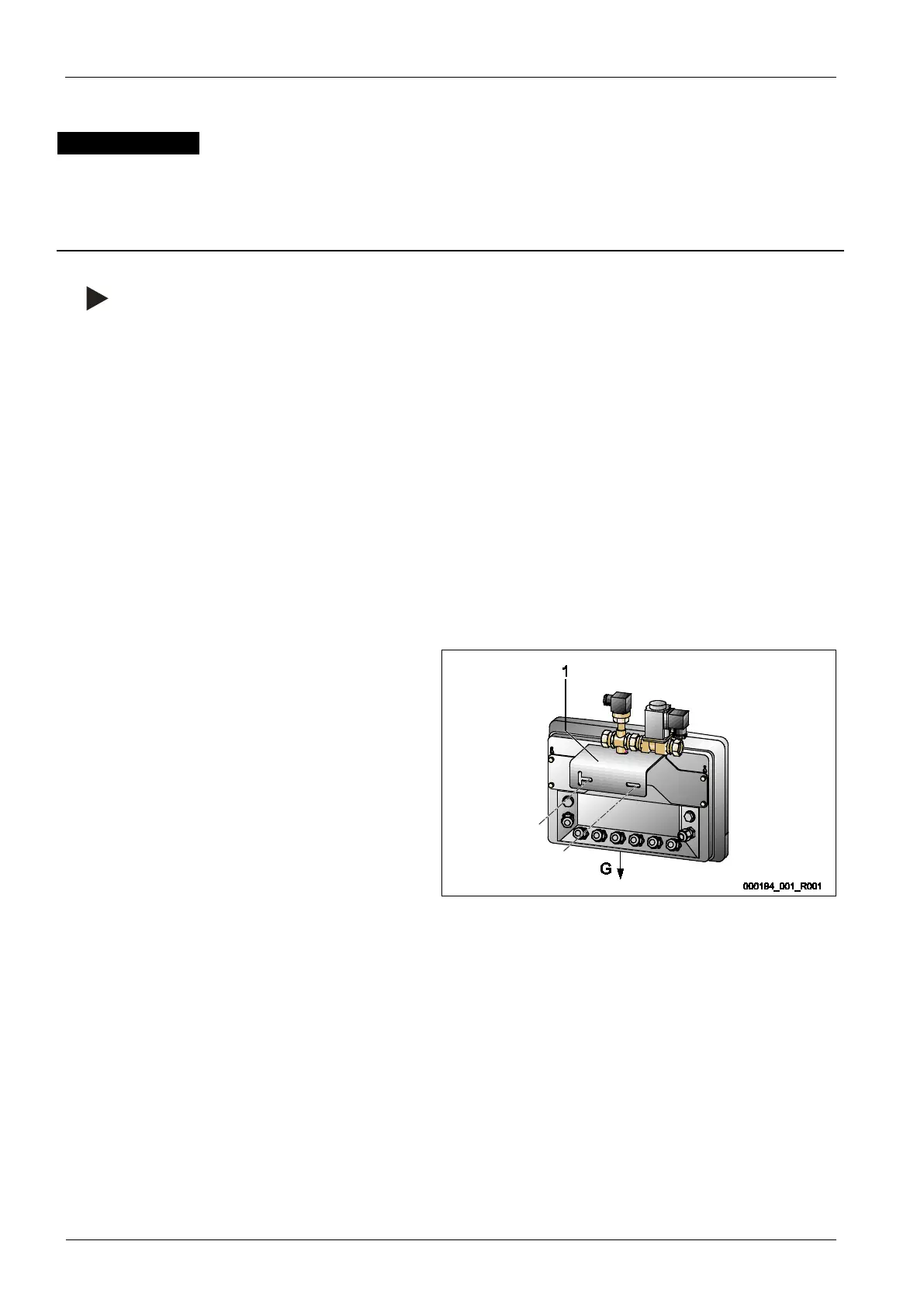

6.3.1 Wall mounting

The device is installed at the wall. Bore holes for wall mounting

are

provided on the rear of the console (1) housing.

Select the attachment means according to the wall properties

and the weight (G) of the device.

During installation, ensure that:

The device is installed sufficiently close to the diaphragm

expansion tank. You ensure so that the "PIS" pressure

sensor is able to measure the filling pressure.

The fixtures can be operated.

The feed connections of the pipes are not adversely

affected.

Loading...

Loading...