ST 1, STR 1 15

4. Adjusting of actuator

Abide by safety measures!

After mechanical connection, electrical

connection and checking of connection and

function start setting and adjustment of the

device. The adjustment can be performed at a

mechanically and electrically connected EA.

This part describes adjustment of EA to

specified parameters in case that any unit of

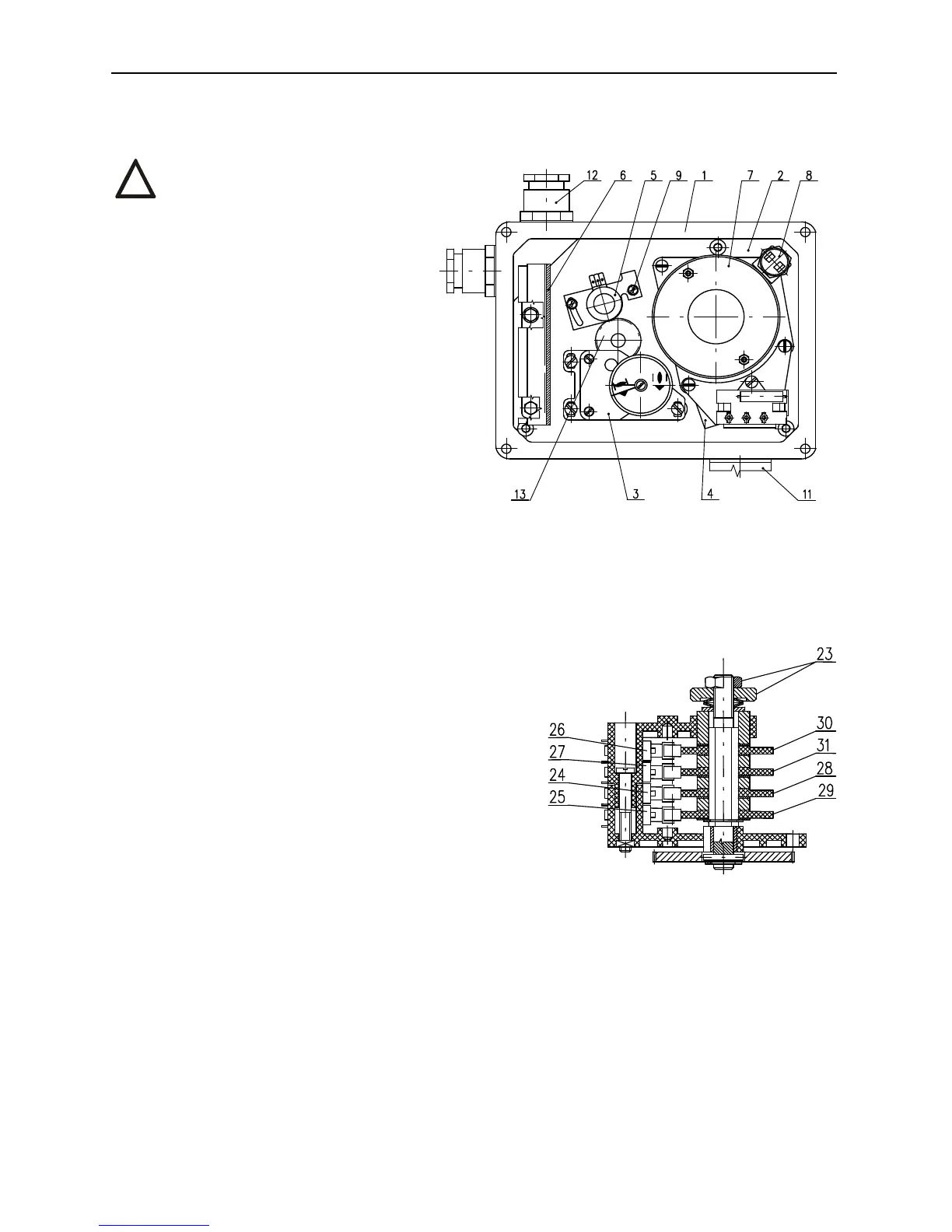

EA is reset. Laying of adjusters of the control

board is shown on Fig. 3

4.1 Gear unit adjustment

In the production plant switching-off

thrust for both the "opening" direction (the

thrust switch S1) as well as for the "closing"

direction (the thrust switch S2) are adjusted to

specified value ±10%. If not agreed else they

are adjusted to maximum value.

Adjustment and setting of the gear unit to other values without any testing device for thrust measuring is

not possible.

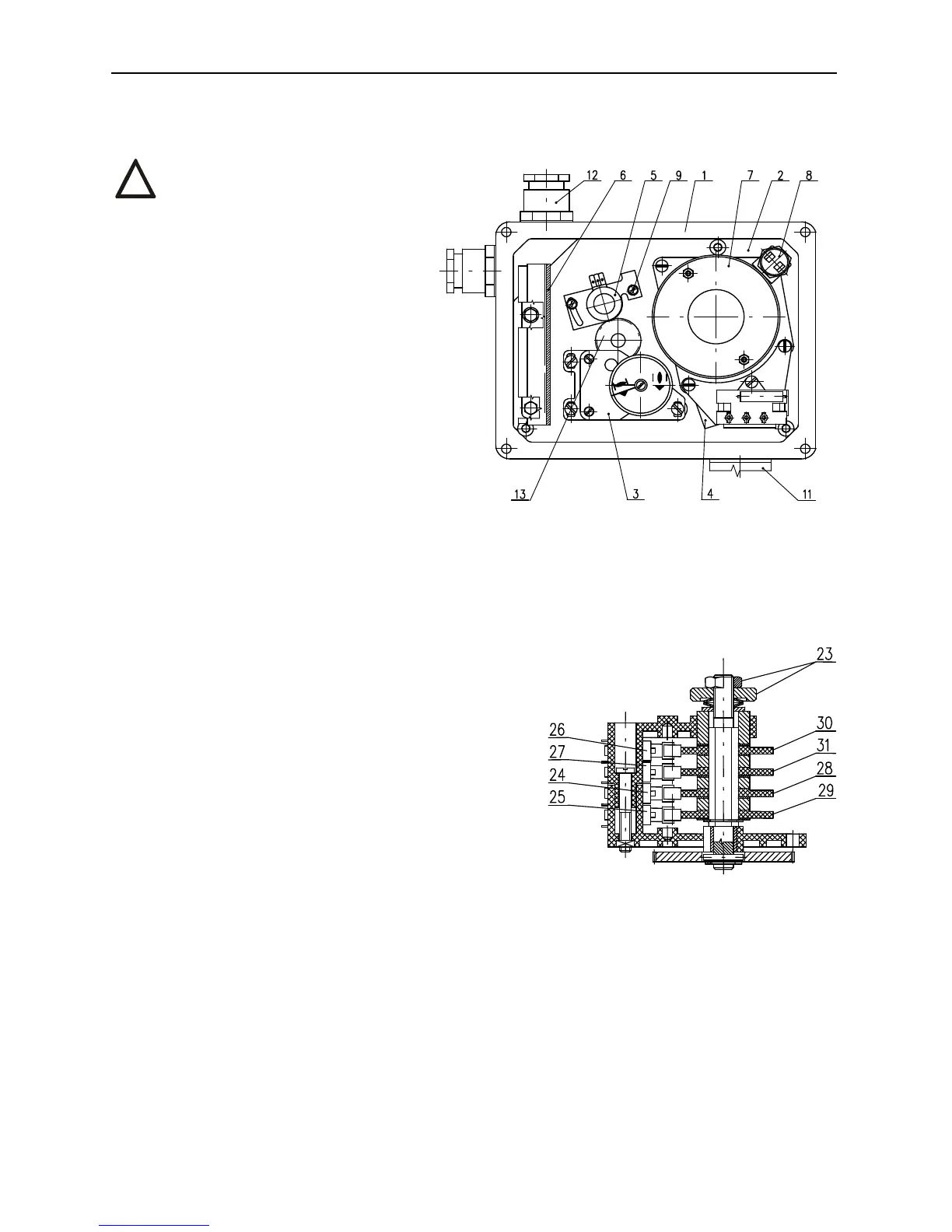

4.2 Adjustment of position-indicating unit (Fig.4)

The EA are in the production plant adjusted to a fixed

angle (according to the specification), given on the nameplate.

While setting, adjusting and resetting follow these steps (Fig. 4):

• In the version with a transmitter put the transmitter out of

mesh.

• Loosen the nuts (23) fixing cams still having the Belleville

spring creating axial pressure.

• Put the EA to the position "open" and turn the cam (29)

clockwisely until the switch S3 (25) switches.

• Change setting of the EA by the angle, where the position

"open" is to be indicated and turn the cam (31) clockwisely

until the switch S5 (27) switches.

• Put the EA to the position "closed" and turn the cam (28)

counterclockwisely until the switch S4 (24) switches.

• Turn the EA back by the angle, where the position "closed" is

to be indicated and turn the cam (30) counterclockwisely until the switch S6 (26) switches.

• Having the EA adjusted lock the cams with the central milled nut and counter-nut (23).

If not agreed else the signalling cams are set next to the limit positions. The signal possibility is available

along the whole operation angle in both directions, i.e. 100%.

!

Fig. 4

Loading...

Loading...