ST 1, STR 1 21

5. Service, maintenance and troubleshooting

5.1 Service

1. In general it is provided that service of the EA is performed by a qualified worker in accordance with requirement

given in Chapter 1!

2. After putting the EA into operation it is needed to verify whether during manipulation any scratch on surface

occurred, it is to be removed to prevent actuator against corrosion!

The EA ST or STR requires just negligible service. Proper putting into operation is a recondition of reliable

operation.

The service of the EA leads from the operation conditions and usually resides in information processing

for further arranging of required functions.

The stuff has to perform prescribed maintenance to prevent the EA during operation against impacts of

environment, which exceed the frame of allowed influences.

Manual control:

If needed (during adjusting, function checking, failure etc.) the stuff can change setting of the controlled

body using the hand wheel. While rotating the hand wheel clockwisely the output part moves in the direction "Z -

closed".

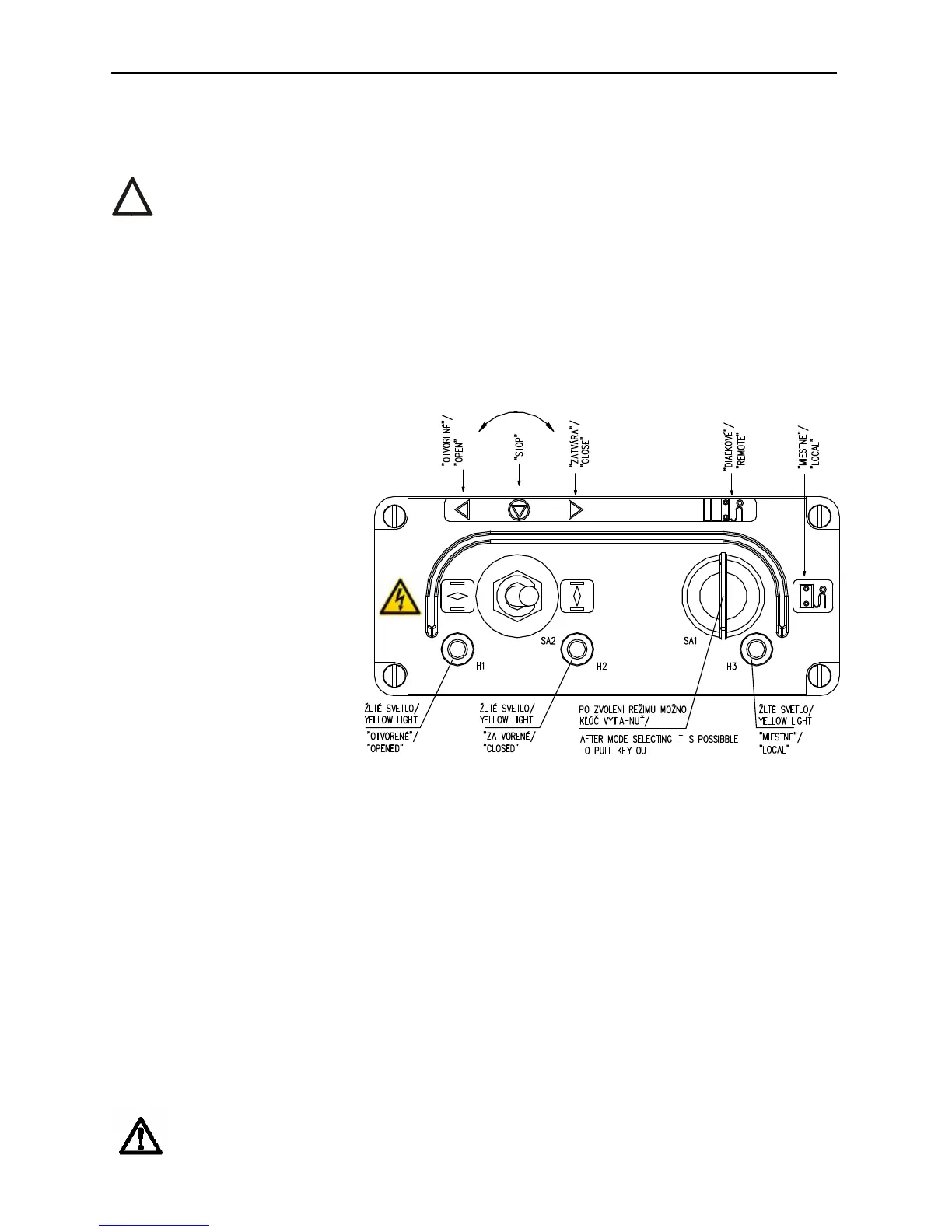

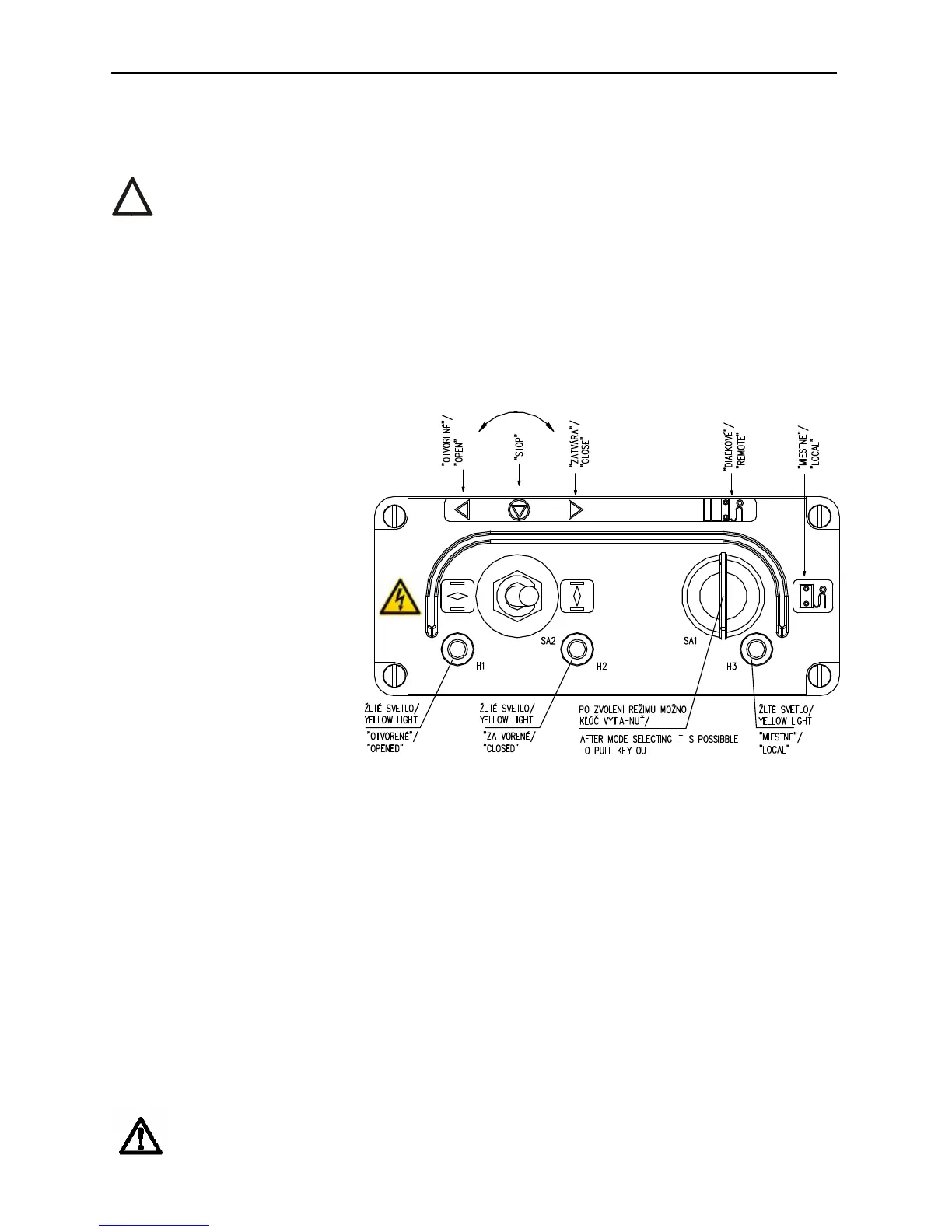

Electric local control: - additional

equipment

In case of need (during

adjusting, function checking etc.),

but power supply must be provided,

is possible to readjust actuator by

electric local control. After switching

the mode switch to the mode

“LOCAL” it is possible by the

direction switch to control motion of

the output part to setting direction.

Signal lights indicate achievement of

limit position at relevant direction.

5.2 Maintenance - extent and periodicity

During inspections and maintenance is needed to tighten all screws and nuts that affect the tightness and

coverage. Similarly, once a year should be checked and if necessary tighten mounting screws of the terminal

wires and assuring of the slip-on joints with wires.

The interval between two preventive inspections is four years.

The replacement of cover gaskets and gasket of an oil filling is needed in case of damage or after 6 years of the

operation.

The grease in the supplied actuators is designed for the lifetime of the product.

It is not necessary to change the grease during the operation of the actuator.

Lubrication:

• - gear part - in versions for climate with temperatures -25°C till +55°C – grease HF 401/0 (GLEIT-µ) resp.

GLEITMO 585 K

- in versions for climate with temperatures -50°C till +40°C grease ISOFLEX TOPAS AK 50.

• - linear adapter – grease GLEIT- µ - HP 520M (to –25°C) resp. HP 520S (to –40°C).

Lubrication of the valve stem is independent on maintenance of the EA!

!

Fig.10

Loading...

Loading...