ST 1, STR 1 19

• Connect the control signal to the terminals 86 and 88

The user has to arrange grounding of the 2-wire circuit of the capacitive transmitter to the electrical

ground of a joined controller, computer, etc. The grounding should be performed only in one place in

any part of the circuit outside the electric actuator!

Note:

The trimmer (20) can be used to adjust the output signal of the capacitive transmitter to any value of operation

stroke in range from ca 40% up to 100% of the value of the operation stroke adjusted by the producer and stated

on the actuator′s nameplate.

4.6 Adjustment of position controller (Fig. 9)

The built-in position controller REGADA of new generation is a user-friendly control system to control

actuators with an analogue signal. The controller takes advantages of high-power RISC processor

MICROCHIP to perform all functions. It provides also continuous automotive diagnostics of the system,

error messages as well as number of relay switching and number of controller's operation hours. Placing an

analogue signal onto the input terminals of the terminal board 86/87 (GND, -) and 88 (+) causes that the EA

output is reset.

Required parameters and functions can be programmed using function buttons SW1 - SW2 and LED

diodes D3 - D4 placed directly on the controller, see Table 2.

4.6.1 Setting of controller

The controller's microprocessor unit is in the production plant programmed to parameters given in

Table 2 (Note 2).

Setting of the controller is performed using buttons and LED diodes. Adjust the position and thrust

switches and the position transmitter before adjustment of the controller.

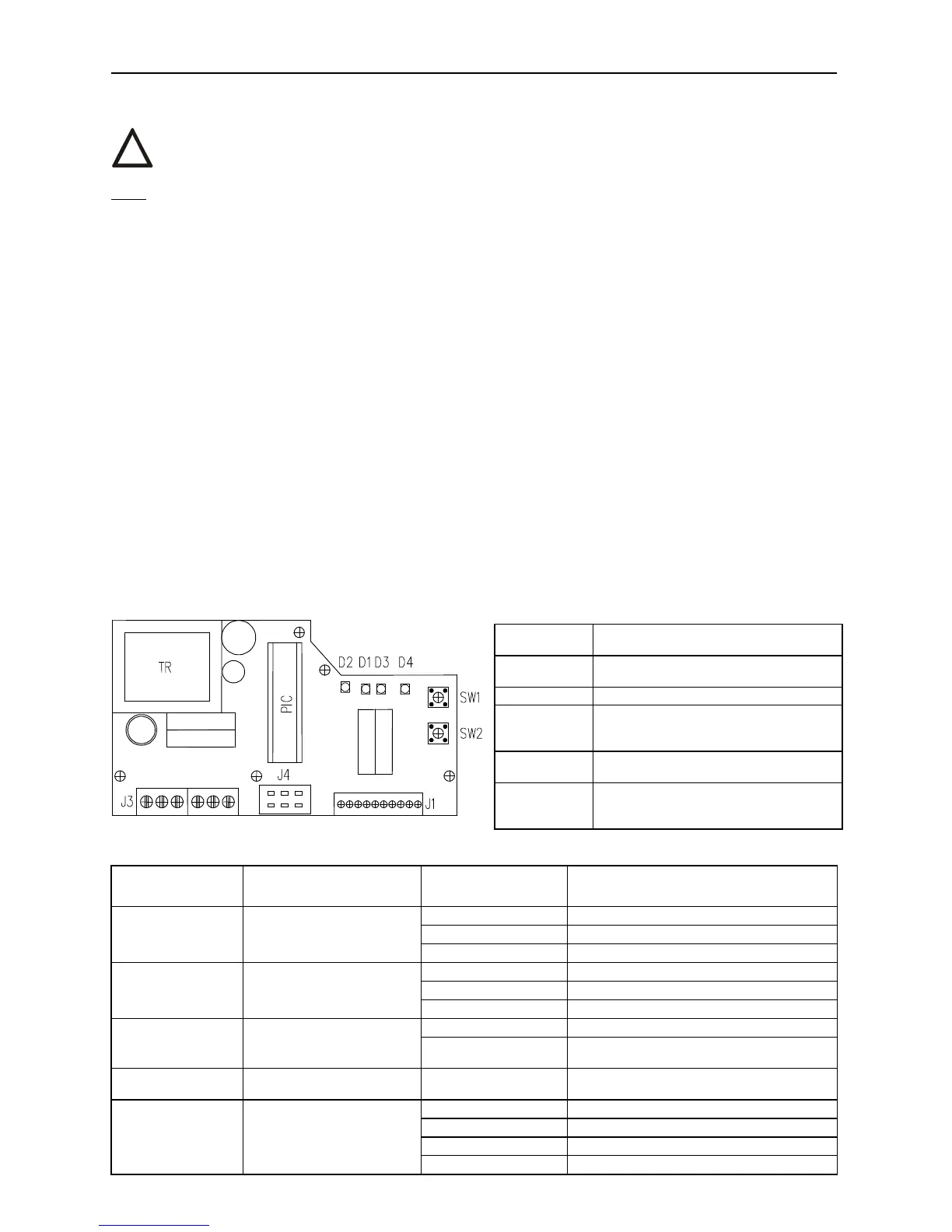

Laying of adjusters and signalling elements on the board of the REGADA controller is shown on Fig.9:

Fig. 9

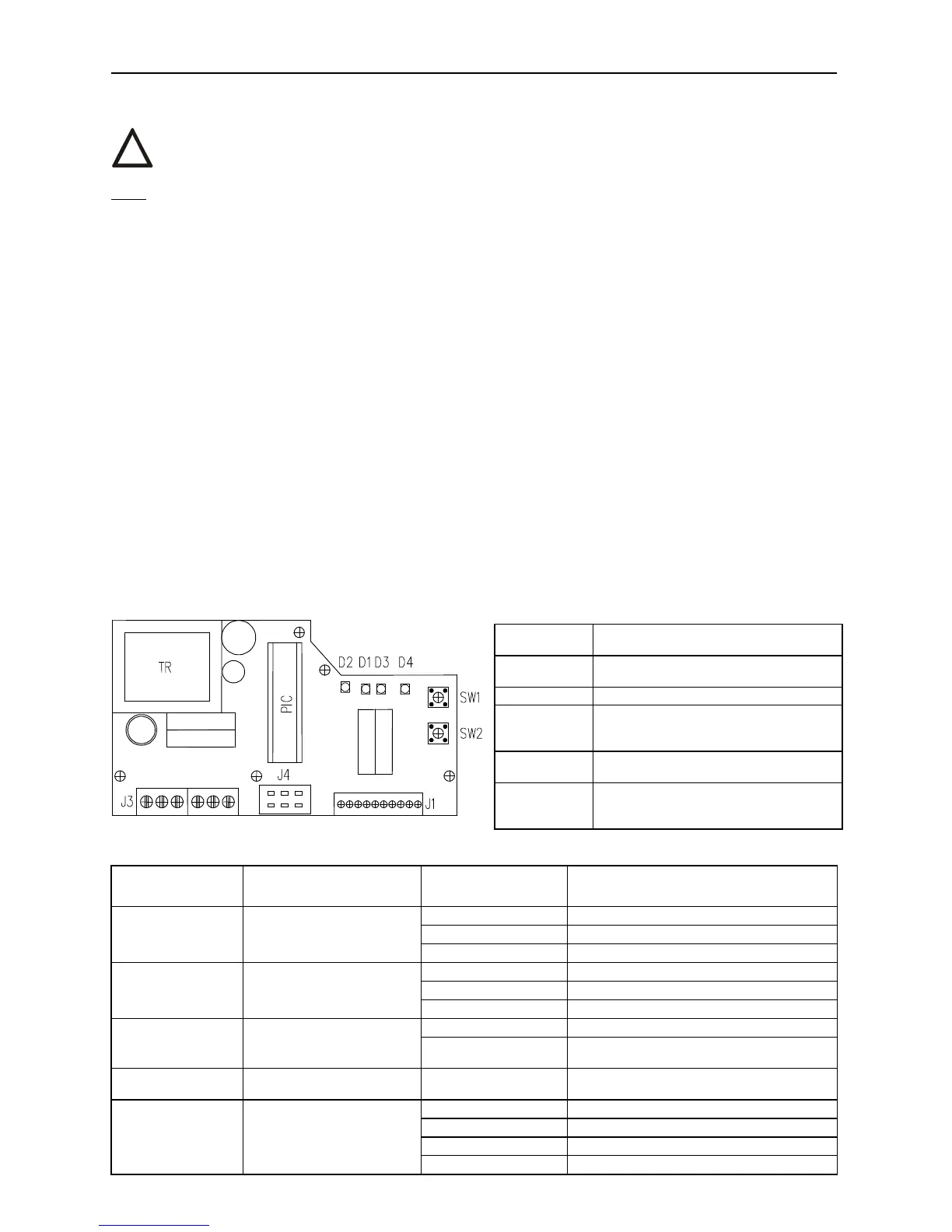

Table 2

D3 (yellow) diode

number of blinking

Adjust menu

D4 (red) diode

number of blinking

Adjusted parameter

1 blink 0-20mA

2 blinks

4-20 mA (*) (**)

1 blink control signal

3 blinks 0-10V DC

1 blink EA opens receiving signal SYS

2 blinks EA closes receiving signal SYS

2 blinks

response for signal

SYS-TEST

3 blinks

EA stops receiving signal SYS (*)

1 blink EA CLOSING at increasing of control signal

3 blinks

mirroring

(ascending/descending

characteristics)

2 blinks

EA OPENING at increasing of control

signal (*)

4 blinks insensitiveness of controller 1 to 10 blinks

insensitiveness of controller of 1-10%

(3% set by the producer) (*)

1 blink narrow thrust

2 blinks

narrow position (*)

3 blinks wide thrust

5 blinks way of regulation

4 blinks wide position

SW1 button

starts an initialisation routine an allows

listing in the adjust menus

SW2 button

setting of parameters in the chosen

menu

D1 diode

power on indication

D2 diode

motion to the direction "opening"

indication (green) - "closing" (red)

indication

D3 diode

(yellow light) number of blinking codes

indicates chosen adjust menu

D4 diode

(red light) number of blinking codes

indicates adjusted parameter of the

controller from the chosen menu

!

Loading...

Loading...