UG-OPUS® 5-80R

OPUS® 5-80R Pre-packed Chromatography Columns

2. If column storage solution is alcohol based, run equilibration buffer at low flow rate (i.e. 50

cm/hr) for 2-3 column volumes. Because Ethanol solution is more viscous than water, the

flow rate of this step should be chosen such that the pressure drop on the column does not

exceed the maximum operating pressure.

3. After the storage solution has been removed, condition the column with the equilibration

buffer for 1-2 column volumes at column qualification testing flow rate.

4. Proceed to testing the column:

4.1. Note: refer to your column’s CoA or CoQ for the test “Mobile Phase” and “Testing Flow

Rate” used by Repligen.

5. Conduct a pulse injection with 1-2% CV of the Injection Solution.

5.1. Note: refer to your column’s CoA or CoQ for the “Injection Solution” and “Injection

Volume” used by Repligen.

6. Elute with mobile phase for 1-2 CV at the same test flow rate while monitoring UV or

conductivity depending on the Injection Solution.

6.1. Salt injection solutions are typically analyzed with a conductivity meter while acetone

injection solutions are analyzed with an UV meter.

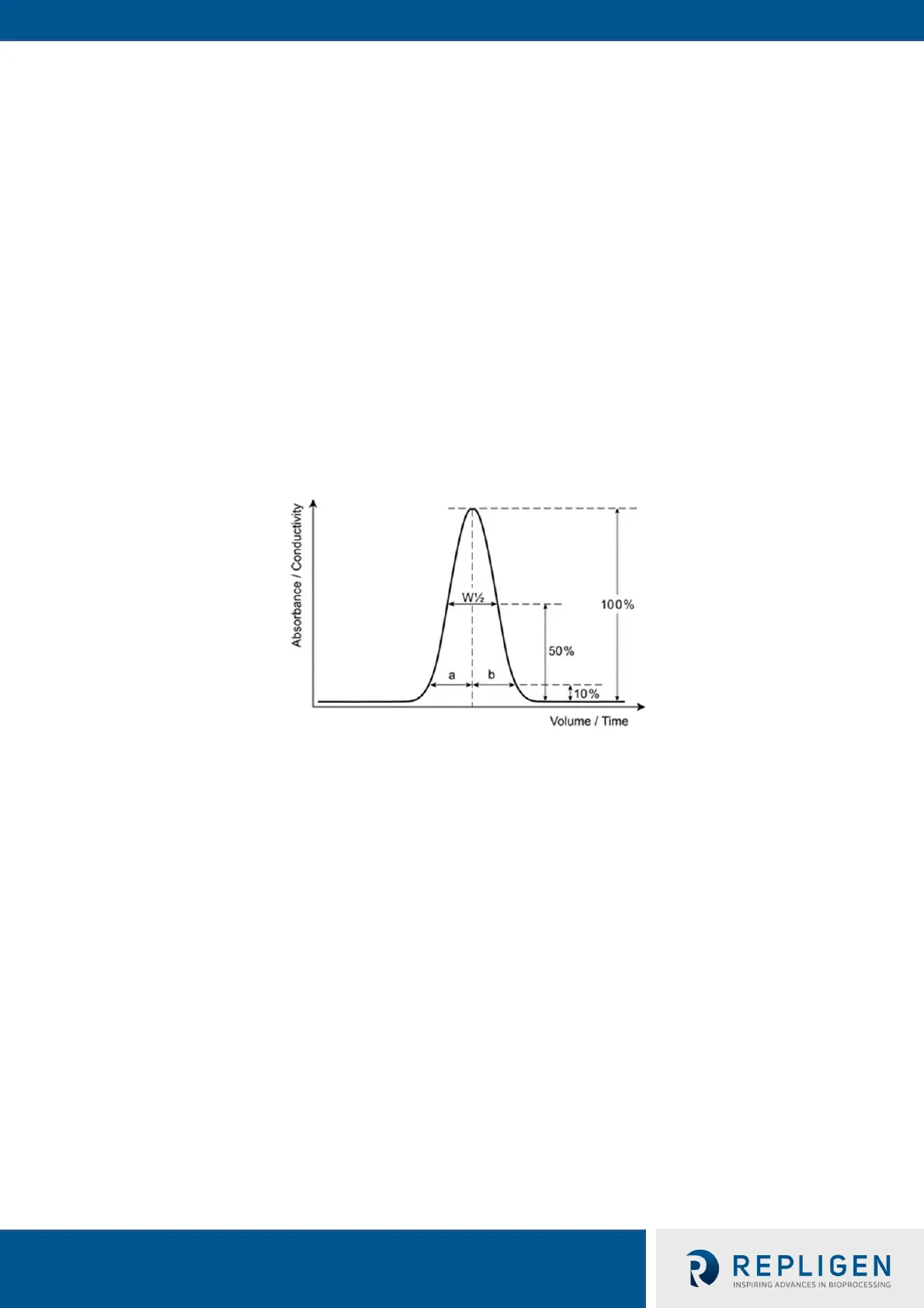

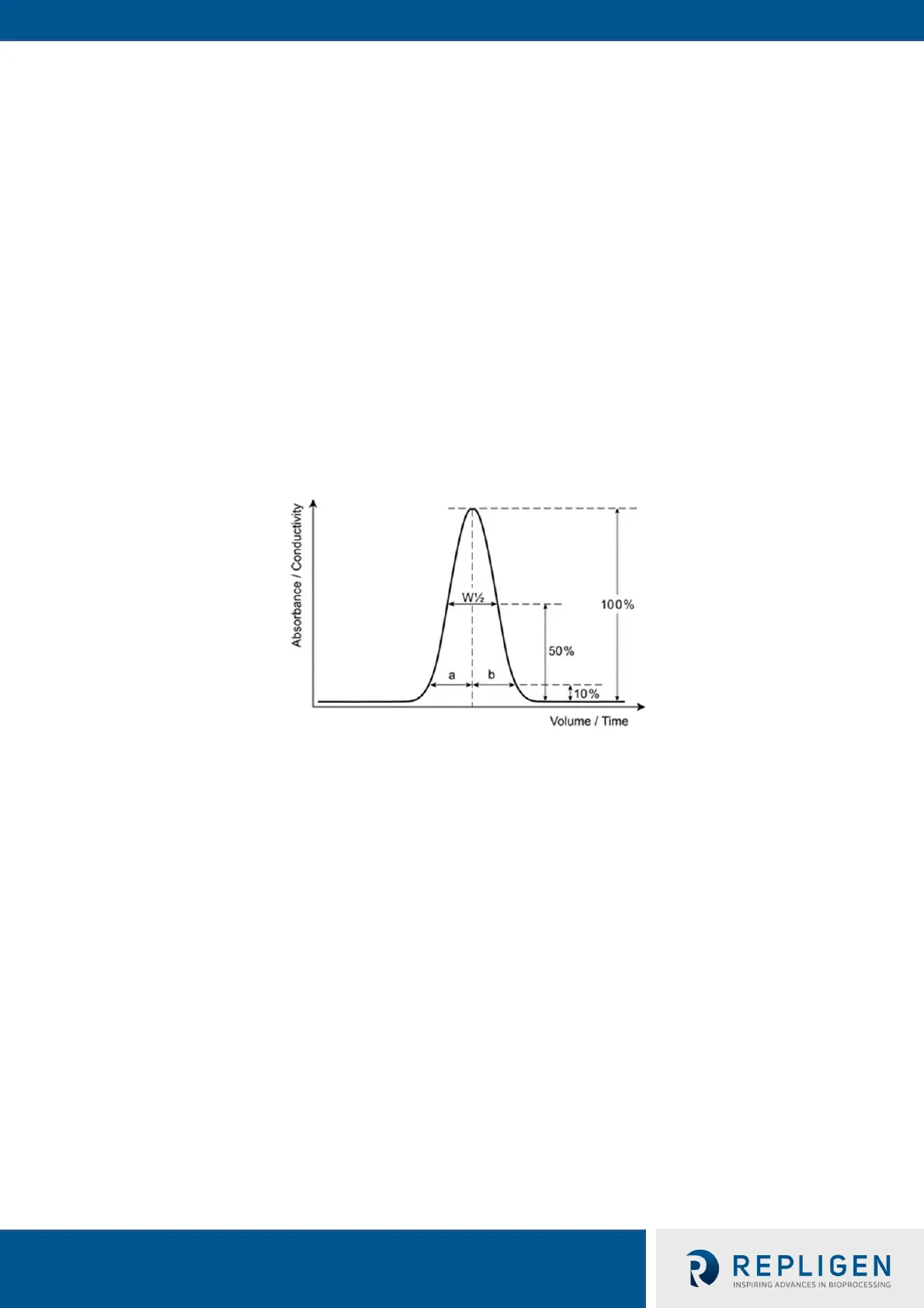

6.2. Calculate number of theoretical plates and asymmetry of the eluted peak:

Figure 8. Absorbance / Conductivity Graph

Theoretical Plate

Count: N= 5.54 x (V

R

/W

1/2

)

2

, assuming a Gaussian peak

Where:

N = number of theoretical plates

V

R

= peak retention (elution) volume

W

1/2

= peak width at half height

Asymmetry: As = b/a

Where:

a = partial peak width at 10% of the peak height for the leading part of the peak

b = partial peak width at 10% of the peak height for the tailing part of the peak

If the plate count and asymmetry measurements are within defined acceptance limits (reference the

column’s CoA or CoQ “QC Release Data”) then the column should be considered fit for purpose.

Loading...

Loading...