/ 17

If it is necessary, invert the direction connection of the motor connector on

RAMPS board.

Launch the heating according to the sort of plastic lament:

• For PLA: from 200° to 210° and 50° for the PCB heatbed (Cover the plate

with Polyimide for a better adhesion)

• For ABS: from 230° to 250° and 90° for the PCB heatbed, (spread ABS juice*,

on the plate cover of polyimide, with a brush to have a better adhesion)

* ABS juice: Dissolve ABS lament in some acetone to obtain a liquid mixture.

For instance : In a glass, pour 10 cl of acetone and add 10cm of ABS lament,

thicken with more lament if the adhesion is not sucient.

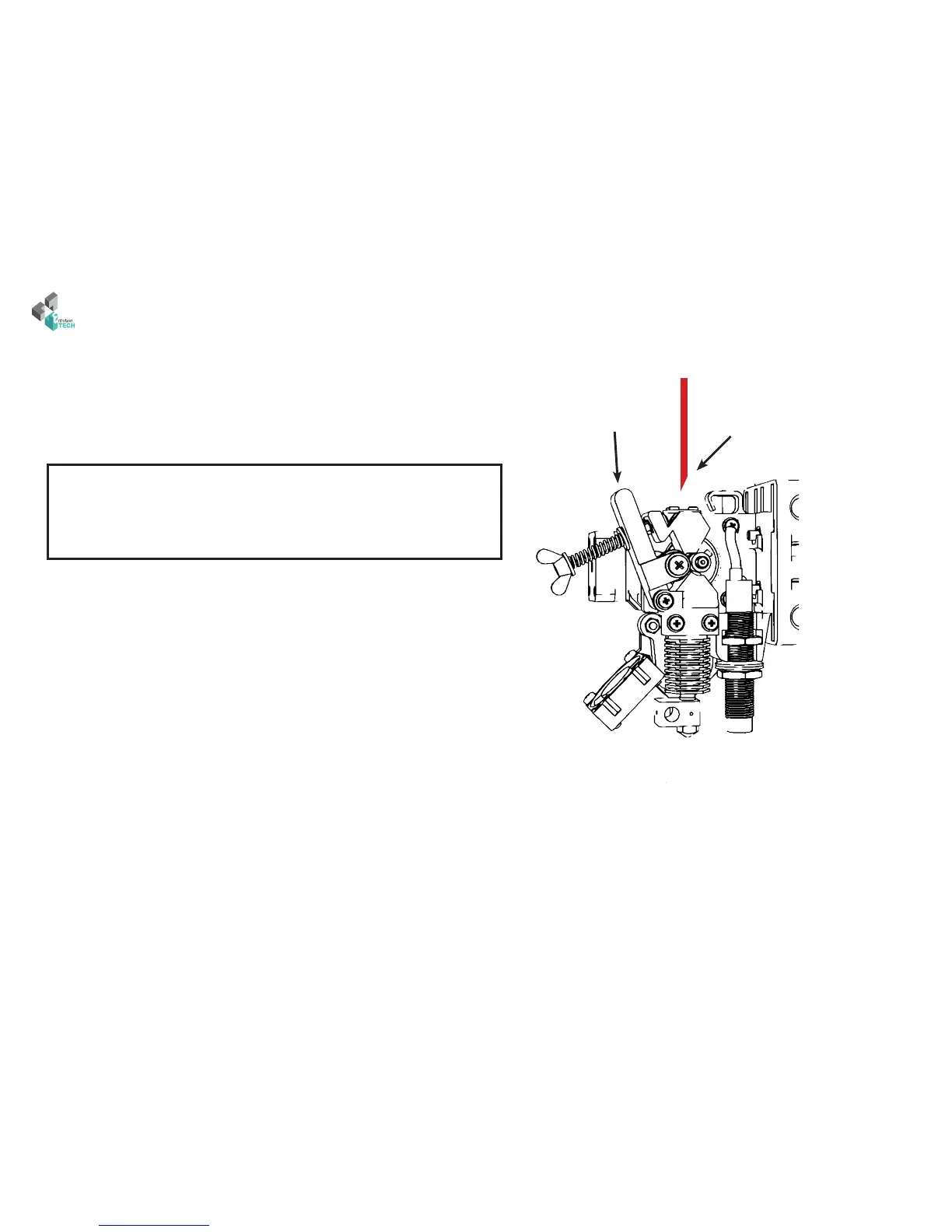

Insert plastic lament 1.75 mm in the extruder by pushing on the Extrudeur Idler

(xed on a spring) to free access to the lament.

When you have reach the temperature, use manual command to extrude.

Check that your hotend have no leak, if it is, it means that you had not well build or tighten your extruder.

Check also that the drive wheel well train the lament continuously and without slippage. In a rst time, you can re-tighten the spring.

Cut the lament extremely beveled to

insert easily your lament in the extru-

der

Push

Loading...

Loading...