Form I-MAPSIII&IV, P/N 222917R9, Page 17

Assembly and

Installation Instructions

for Option CJ49

and CJ50, Curbs for

Horizontal Airow

Counter

Flashing

(by installer;

install after

curb assembly)

Insulation

2 x 4 Wood

Nailer

Cabinet

Cant Strip

(by installer)

Weld, bolt,

or lag screw

curb to deck

structure.

1” Lag Screw and

Lockwasher

(1 per corner)

(4 per corner) 3/4” Hex Head

Cap Screws with Lockwashers

and Hex Nuts

A

B

B

Return

Air

Cap

3 C’s

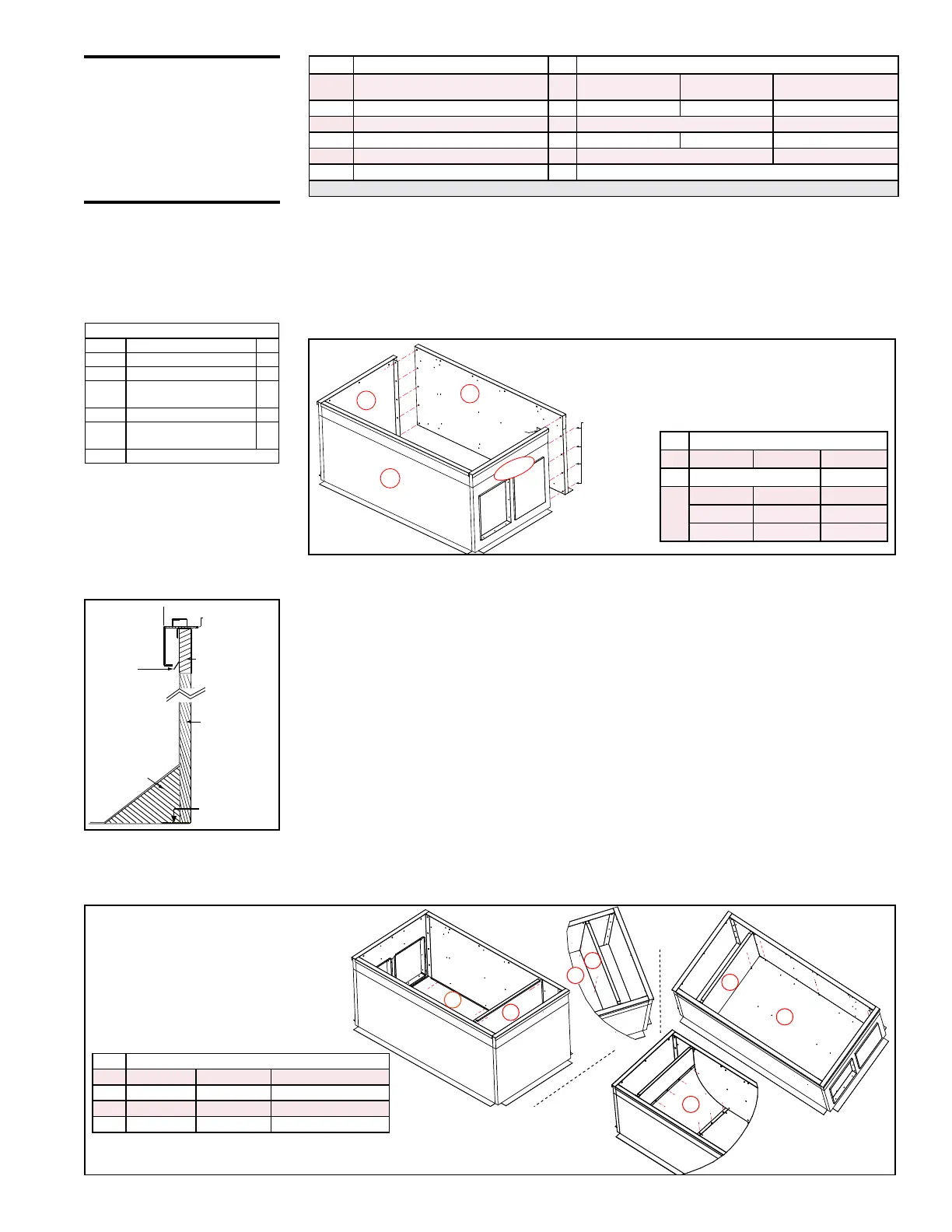

FIGURE 9A - Assemble Curb Ends (A&C) and

Curb Sides (B&B)

3. Check the assembly for squareness. The curb must be adjusted so that the

diagonal measurements are equal within a tolerance of ±1/8” (±3mm).

4. Level the roof curb. To ensure a good weatherproof seal between the unit curb

cap and the roof curb, the roof curb must be leveled in both directions with no twist

end to end. Shim as required and secure curb to roof deck. (NOTE: Install internal

ducts before ashing; see Step 5.)

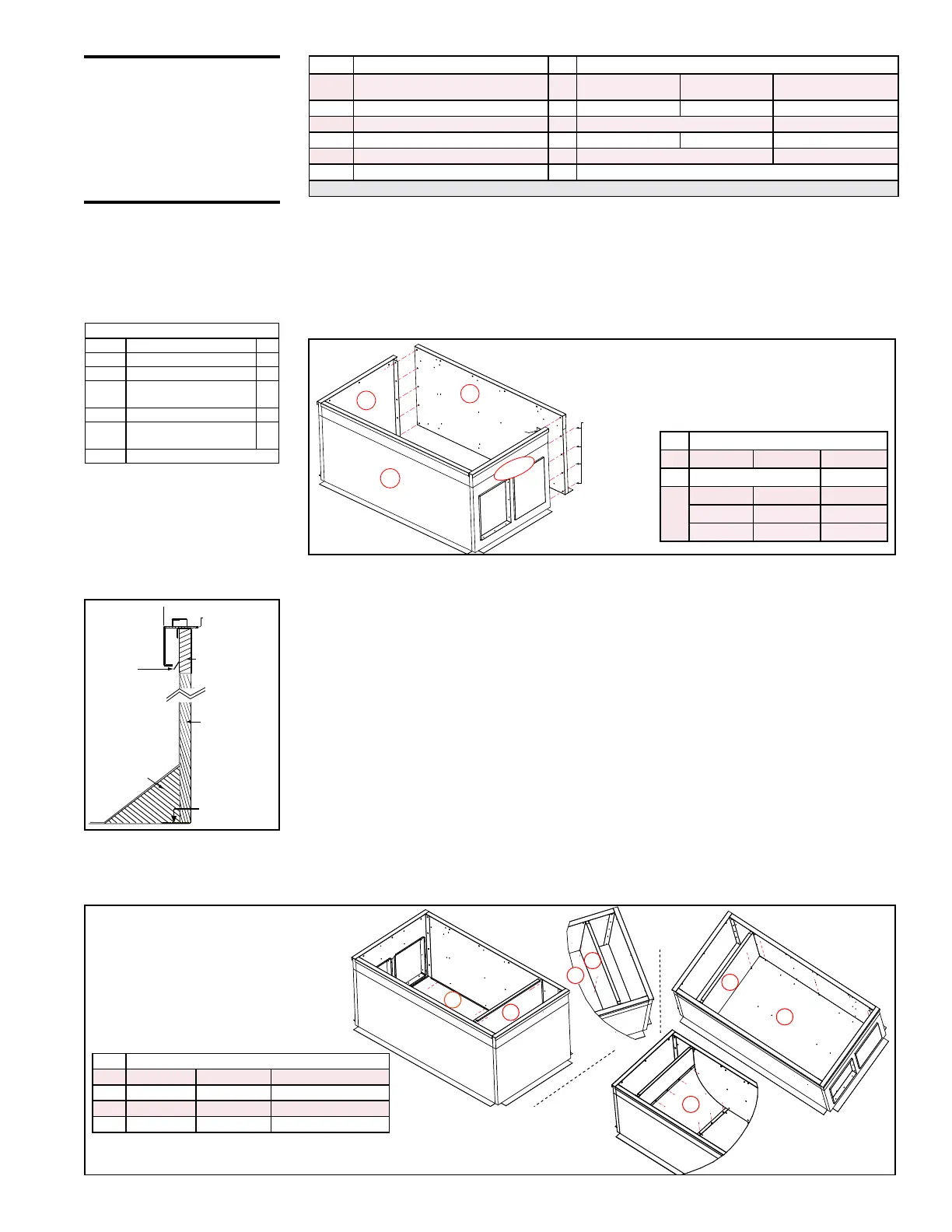

5. Install solid partition (Code D), duct bottom (Codes E & F), and air bafe (Code

G) using sheetmetal screws (See FIGURE 9C).

a) Position the solid partition (Code D) with insulation side toward the solid end

of the curb. Align the holes (push the insulation out of the way) and attach

partition to curb sides (B & B).

b) Position insulated duct bottom (Code E) with insulation side up in the bottom

of curb. Align the holes (push the insulation out of the way) and attach

partition to curb sides (B & B). Attach the bottom to partition (D).

c) Position the bottom liner (Code F) over the insulation in the bottom of the

curb. Align the holes and attach around the perimeter.

d) Position the air bafe (Code G) against the partition (D). Align the holes and

attach. Align the air bafe with the holes in the bottom liner (F) and attach.

FIGURE 9B -

Curb Detail

CAUTION: Before

installation, recheck to

be sure that the curb

selected matches the

unit ordered. Verify

the dimensions of the

curb received with the

dimensions on page 19.

ID Description (cont'd)

Qty

Component P/N's (cont'd)

L

Divider (upper part) between Supply

and Return Air Ducts

1

261667 261668 261678

M Duct Divider Top Liner

1

261408 261409 261426

N Duct Divider Bottom Liner

1

261405 261424

P Supply Air Duct Large Top (insulated)

1

261664 261665 261676

Q Supply Air Duct Small Top (insulated)

1

261669 261679

Hardware Bag

1

262438 (see content list, left below)

* See Model Size / Cabinet Size Cross Reference on page 2. ** Curb bottom in Cabinet C is 2-piece.

A

B

B

C

D

E

D

F

D

E

A

A

B

B

Install D and E

(See NOTE).

Install F

(See

NOTE).

B

A

D

F

B

G

Install

G.

FIGURE 9C - Install Supply

Duct Partition (D), Bottom

(E), Bottom Liner (F), and Air

Bafe (G)

NOTE: Cabinet C - Insulated bottom

(Code E) and Bottom Liner (Code F)

are two piece.

Insulation NOTE: There is no exposed insulation in the ducts.

All insulation in airow paths is covered with a liner.

1. Follow the Steps and refer to the curb assembly drawings

2. Position curb ends (Codes A & "large" C) and curb side rails (Codes B & B) as

shown in FIGURE 9A. Join the corners as illustrated.

Locate the 4-pc bundle labeled (C). Using sheetmetal screws from the hardware

package, attach the duct ange pieces to both the inlet and return air openings.

If not using return air in the installation, position the return air cap (C) over the

opening and attach. If a return air duct will be used, the cap is not needed.

Assy Hardware Bag, P/N 262438:

P/N Description Qty

1035 Nut 5/16" Hex-18 Thread 16

1333 Lockwasher 5/16 In. 20

16243

Hex Hd Lag Bolt 5/16” x

1-1/4”

4

16247 Cap Screw 5/16 X 3/4" 16

11813

S/M Screw #10-16x1/2

Ab Stalgd

125

66302 1-1/4x1/4 x 50 ft Sealant Tape

ID P/N by Cabinet Size

A A-261653 B-261654 C-261670

B A&B-261655 C-261671

C

A-261656 B-261657 C-261672

A-

261386

B-261387 C-261414

A-261388 B-261389 C-261415

ID P/N by Cabinet Size

D A-261658 B-261659 C-261673

E A-261660 B-261661 C-261674 & 261428

F A-261394 B-261395 C-261418 & 261429

G A-268604 B-268605 C-268606

Loading...

Loading...