33

I-SCE (09-18) PN207697R9

The gas supply (refer to pressure requirements in Table 17) connects to the single-stage gas valve. To compensate

for additional pressure loss through the modulating valve, the single-stage gas valve has a custom outlet pressure

setting higher than when it is used on a standard gas manifold. The pilot tubing connects to the pilot port on the

single-stage gas valve. When the valve receives a call for heat from the amplifier and pilot is established, gas flow

from the single-stage valve goes to both the modulating valve and the regulated lighter tube system. When the signal

from the amplifier to the modulating valve requires less-than-high fire operation, the modulating valve functions to

lessen the gas flow to the burner to reduce the input rate to that required to maintain the desired temperature. When

the input rate is reduced enough to decrease the gas pressure to 1.1 IN WC, the primary gas pressure switch in

the manifold activates the gear motor that controls the bypass damper in the venter/combustion air system. The

bypass damper opens to divert some of the incoming air directly into the flue duct and to reduce air flow through the

burner. Safety switches monitor the position of the bypass damper. When the gas pressure increases above 1.1

IN WC, the bypass damper closes.

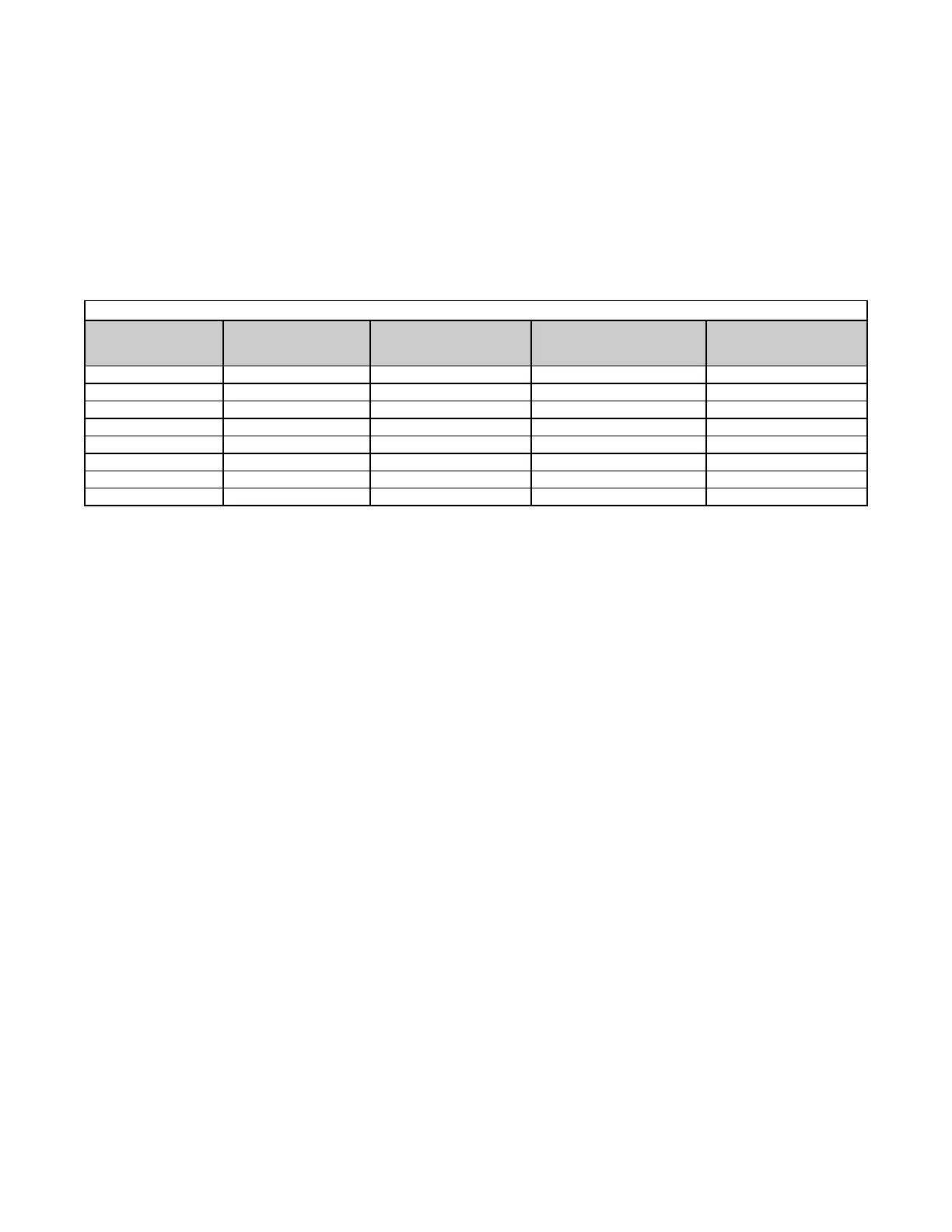

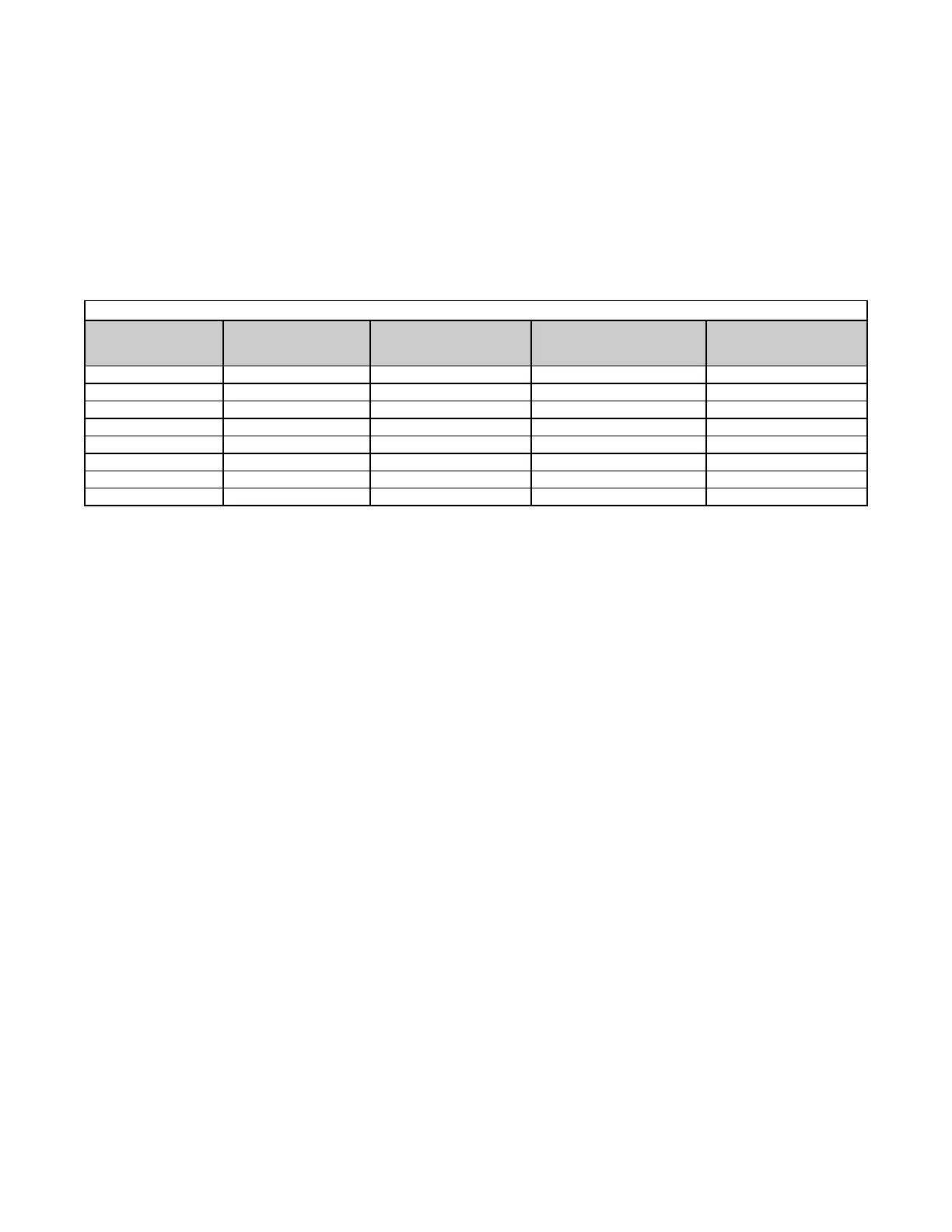

Table 17. Options AG39 and AG40 Pressure Requirements

Model Maximum Turndown MBH Input Range

Factory-Set Inlet Pressure

to Modulating Valve

(IN WC)

Gas Supply Pressure

Required

(IN WC)

125 20% 25–125 3.9 5.0

150 27% 40.3–150 3.7 5.0

175 23% 40.3–175 3.7 5.0

200 26% 51.8–200 3.9 5.0

225 23% 51.8–225 3.9 5.0

250 28% 69–250 4.0 5.0

300 23% 69–300 4.0 5.0

400 25% 100–400 4.4 6.0

Sensor Location: For the convenience of the installer, the duct temperature sensor is factory-installed in the cabinet

leg (see Figure 26). Although the sensor has a mixing tube, at this distance from the discharge it does not receive a

true mix, so the temperature read by the sensor will be slightly higher than the actual air entering the ductwork. The

system will provide comfort level heat if the selector is set slightly higher to compensate for this reading. If a direct

correlation of these two temperatures is required, move the duct sensor to a location in the ductwork about 10–12

feet (3–3.7 M) from the furnace discharge.

Wiring and Service: For wiring, consult the wiring diagram provided with the furnace. All wires in the electrical box

that connect to modulation controls must have a temperature rating of 150°C. This is a unique system which includes

custom-built components and custom settings. If service is required, follow the general guide in TROUBLESHOOTING

and the special troubleshooting guide shown in Figure 29.

Loading...

Loading...