1701ULSA(EC)--EN, p. 12/30

7AIRSUPPLY&FLUESYSTEM

7.1GENERAL

WARNING

Thefluemustbeinaccordancewithallinternationalandnationalrulesandregulationsin

force.Localrequirementsmayapplyinadditiontonationalrequirements.

Failuretoprovideproperflueingcouldresultindeath,seriousinjuryand/orproperty

damage.

Theproductsofcombustionmustbefluedtooutside

atmosphere.Commonflues(formore

thanoneappliance)mustnotbeused.

Singlewallfluepipeexposedtocoldairorrunthroughunheatedareasshouldbeinsulated

toavoidcondensation.

Ifthefluepassesthroughacombustibleelementofthebuildingitmustbeenclosedbya

sleeveofnon‐combustiblematerialandseparatedfromthesleevebyatleasta25mmair

break.Thetemperatureofanycombustiblematerialneartothefluemustnotexceed65°C

whentheheaterisinoperation.Thefluemustbeatleast50mmawayfromany

combustiblematerial.

Provision

mustbemadeforcondensationtoflowfreelytoapointtowhichitcanbe

released,i.e.drain.

ModelULSA/ULSAECheatersmaybeinstalledastypeBortypeCinstallations.Theunitheatersaredesignedto

operatesafelyandefficientlywitheitherahorizontalorverticalfluesystemwheninstalledaccordingtothe

specificrequirementsandinstructions.Ifthisheaterisreplacinganexistingheater,besure

thattheflueisofthe

correctsizeandthattheexistingflueisingoodcondition.Acorrectlysizedfluesystemisrequiredforsafe

operationoftheheater.Animpropersizedfluesystemcancauseunsafeconditionsand/orcreatecondensation.

Theunitsmaybeinstalledasabalanced

fluetypeCheaterrequiringbothacombustionairinletpipeandaflue

pipeorasapowerventedheatertypeBwherethecombustionairistakenfromthespacewhereheateris

installedandwhichrequiresonlyafluepipeexhaustingtooutdoors.Allproductsofcombustionmust

befluedto

outdooratmosphere.

EachheaterinstalledasatypeBappliancemustbefittedwithanindividualfluepipeandthecombustionairinlet

openingmustbeprovidedwithaprotectiongrill.

EachheaterinstalledasatypeCappliancemustbefittedwithanindividualcombustionair/flue

pipesystem.Type

C2appliance,withsinglepipesystemforsupplyofcombustionairandevacuationoffluegasses,arenotallowed.

Fortesting,thefluepipeshouldincludeasealabletestpoint.Ideallythetestpointshouldbeatleast450mmaway

fromtheairheaterflueconnection socket.However

ifaconcentricflueisattacheddirectlytotheconnection

socketsthenthecombustionshouldbetestedthroughtheflueoutletcollarviaadrilledtestpointwhichmustbe

securelypluggedoncompletion.

Followthefluepipemanufacturer’sinstallationinstructionsformakingjoints,includingconnectionstotheair

heater,

forpassingthroughabuildingelementandforsupportrequirements.

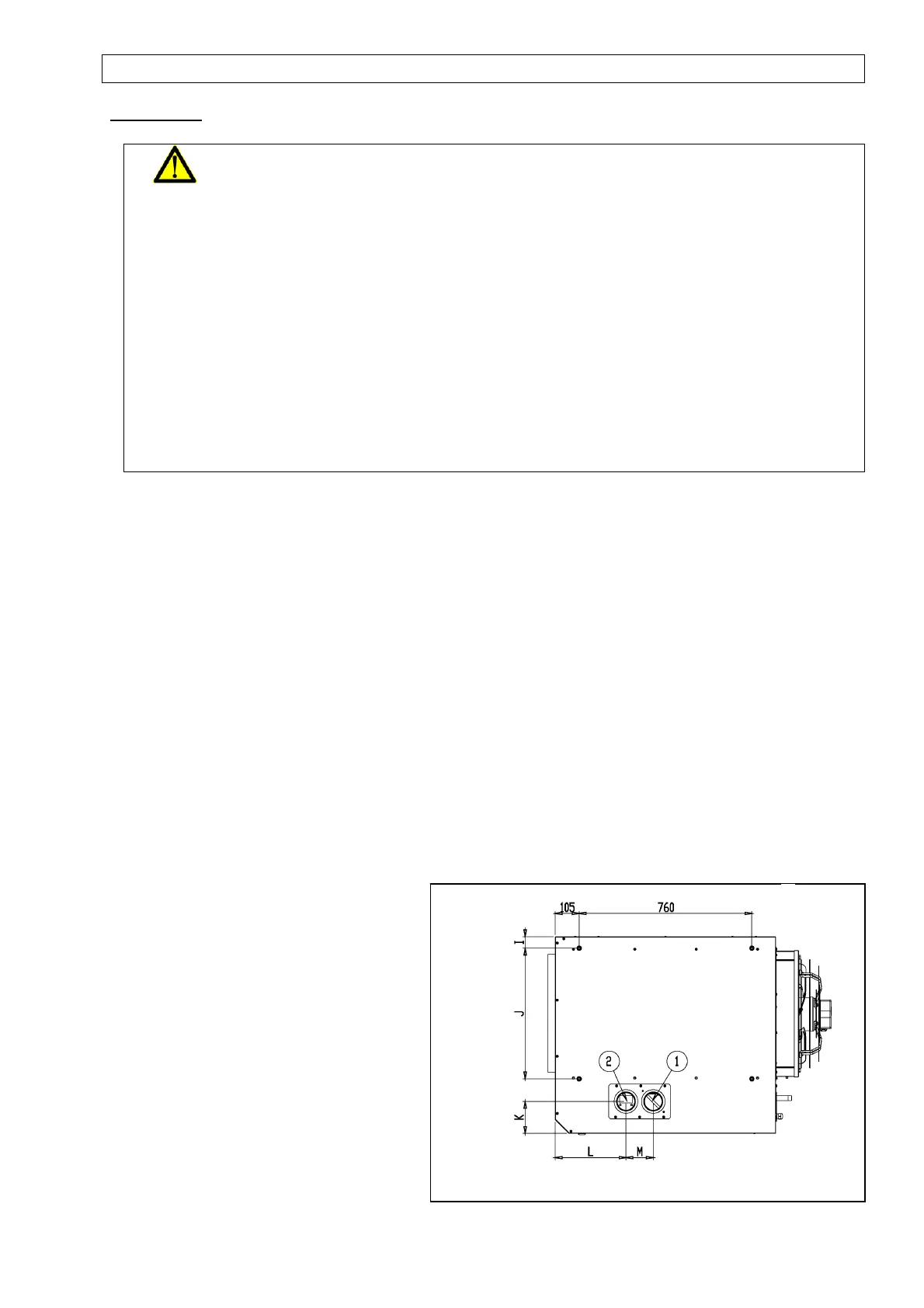

Figure5:

Combustionairandfluepipesockets(standard

version)

Remark:

Acoverplatecanbeinstalledontherearor

toppanel.Theplatewiththefreshairinlet

andtheflueoutletsocketisfactory

installed

onthetoppanelbutcaneasilybereplacedon

therearpanelifrequired.Incaseofchange,a

separatekitmustbeorderedatthesupplier.

Combustionairinlet

Flueconnection

Loading...

Loading...