1701ULSA(EC)--EN, p. 17/30

9GASSUPPLY

GASCONNECTION

Werefertotable1ofsection3forallgasspecifications

WARNING

Connectiontoagasserviceinstallationmayonlybecarriedoutbysuitablyqualifiedpersons.

Thegasinstallationmustcomplywithallrulesinforce.

Onlymaterialsappropriateforgasserviceinstallationmaybeused.

Donotrelyontheheatertosupportthegaspipe.

NEVERUSEAFLAMETOTESTFORGASSOUNDNESS.ALLCOMPONENTSOFAGASSUPPLY

SYSTEMMUSTBELEAKTESTEDPRIORTOPLACINGEQUIPMENTINSERVICE.FAILURETO

COMPLYCOULDRESULTINPERSONALINJURY,PROPERTYDAMAGEORDEATH!

9.1GENERAL

ULSA/ULSAECheatersaredesignedtooperateoneithernaturalgas(G20),propane(G31)orbutane(G30)gas.Check

thatgassupply,gascategory&gasinletpressureisinaccordancewiththedatadescribedontheairheater.Toletthe

unitfunctionatmaximalheatoutput,thegas

supplypipeMUSTbecorrectlysized.Closetotheairheateragastapwith

couplingmustbemountedforservicing(seefigure11).Itisstronglyrecommendedtoplaceagasfilterandcleanthe

gastubewithnitrogen.

Thewholeofthegasserviceinstallationincludingthemetermust

beinspected,testedforsoundnessandpurgedin

accordancewithappropriaterequirementsbyaqualifiedperson.

9.2GASCONNECTION

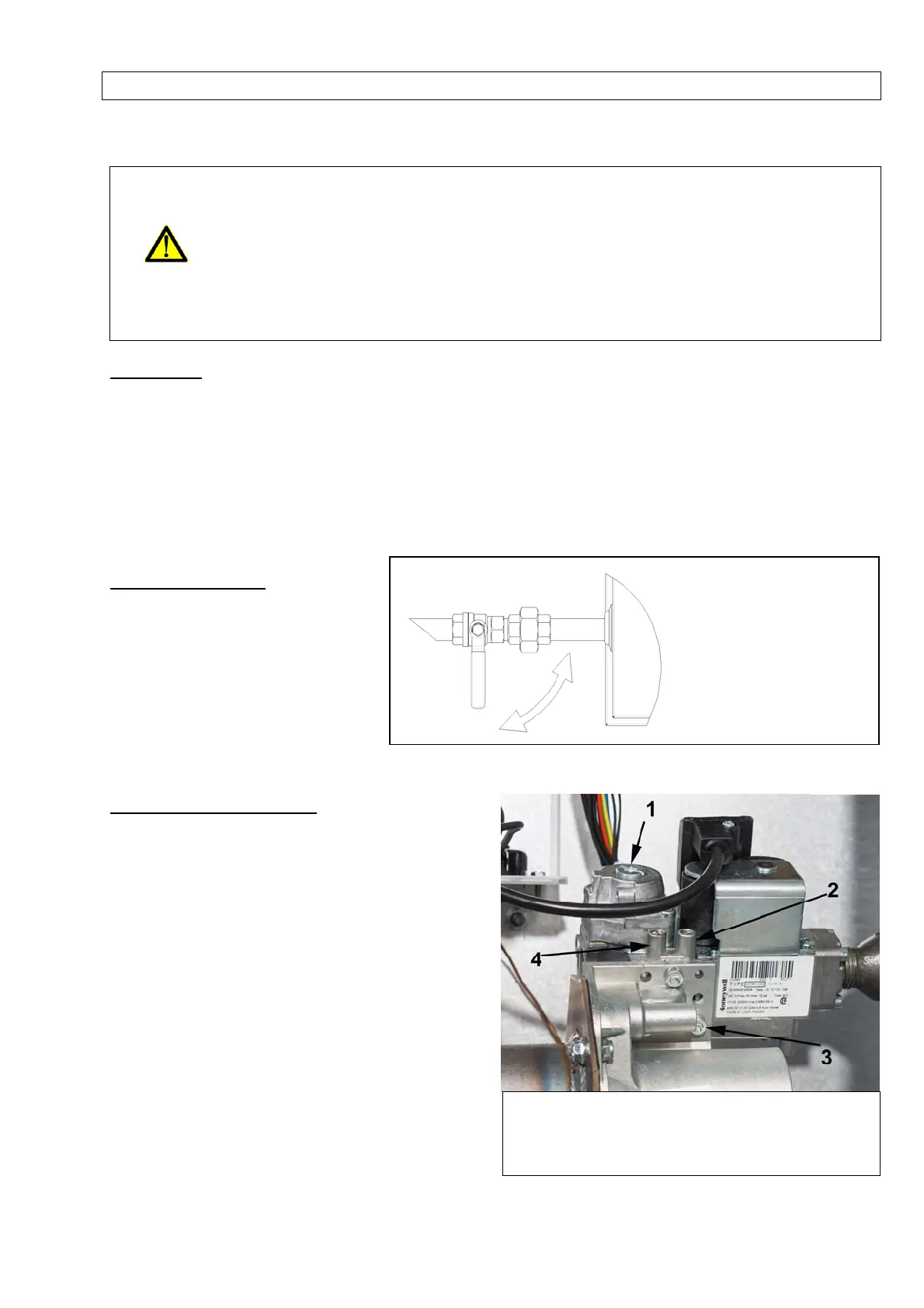

9.3ADJUSTMENTGASVALVE

Toadjusttheoffset,removetheprotectionscrewon

thetopandregulatetheoffsetbyusingtheexposed

screw.Offsetvalueswillbemeasuredintheindicated

points.

ToadjusttheCO

2

,useascrewdriverintheindicated

spotandturnthescrewdriverclockwisetodecrease

themeasuredCO

2

orturnitcounterclockwiseto

increasethemeasuredCO

2

.TheCO

2

measurement

shouldbedoneinthefluedischargepipe.

A

llunitsaresetaccordingtothedataplatebefore

leavingthefactory.Anymodificationtothegasvalve

mustbedonebyaqualifiedtechnician.

1 Offsetadjustmentpoint

2 Inletpressuremeasuringpoint

3 CO

2

adjustmentpoint(throttle)

4

Offsetmeasuringpoint

REMARK:

Donotovertighten

anddonotrotatethe

gasvalveinsidethe

heatercontrol

com

artmen

Figure12

Figure11

Loading...

Loading...