SECTION II: INST ALL ATION AND MAINTEN ANCE

31

II.2.5.4 Inspections

When installation is complete, it is necessar y to:

• Bleed the air c ont ained in th e circuit.

• Ensure that t here are no water l eaks.

• Carefull y co ver the val ve a nd c on necti on pipes wit h 10 mm anti-

condensate material or install the auxiliary tr ays.

• Pour water int o t he c onde nsat e dr ain tra y an d c hec k t ha t the liq uid

drains pr operl y, follo wing it right thr ough t o t he outl et of t he drain-tu be .

If it d oes no t, chec k t he i nclinati on an d lo o k for possibl e bl oc kages.

II.2.5.5 Assembly of the motorised electrothermal

valve

The unit c ontrol circuit onl y allo ws o pe ning of the mot orized valve wh en

the fan motor is working.

When a lower t empera ture is r equired b y th e t her most ats, the outlet V

and H (termin al bl oc ks) is po wered at 23 0V and th e c orrespo nding

chilled wat er or hot water valve is energized.

ATTENTION!

The pump control circuit stops water supply to the

cold v alv e if an irregul ar in cre as e of the cond ensat e

water level is detected into the drain pan.

If a n irregular increas e of th e c ondens ate wat er le vel is det ecte d int o

the drain pan (for e xample: possible de fecti ve drain, pump malf uncti on,

fan motor n ot working) th e c ont act of t he “s afet y level 2” flo at s witch

opens t o clos e th e regulation val ve, sto pping t he c old water fl ow

towards t he coil and a voi ding further condensation.

Regulation

The water flow rate must be chec ked:

• install th e mot orised val ves s upplied as acc essories

or:

• install th e mot orised val ves s up plied by t he i nstaller

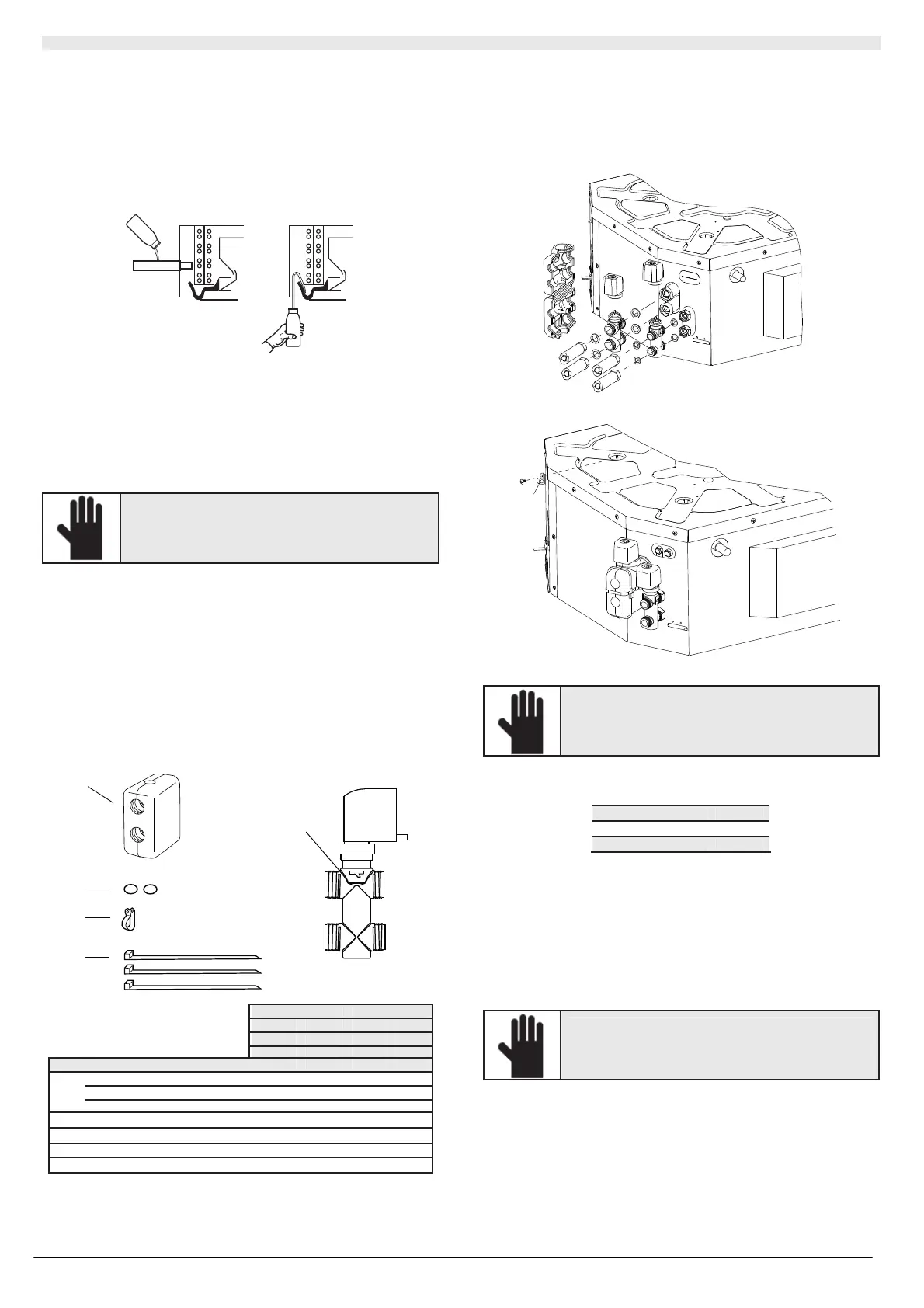

List of components

a

b

c

d

e

22C

2-PIPE 4-PIPE

26 61 26 -

41 86 41 -

51 111 51 111

Ref. Description Q.t y Q.t y Q.t y Q.t y

1” Gas Valve - 1 - 1

¾” Gas Valve 1 - 1 1

a

½ Gas Val ve - - 1 -

b Shell 1 1 1 1

c O-ring 2 2 2 2

d Clip 1 1 1 1

e Clamp 3 3 3 3

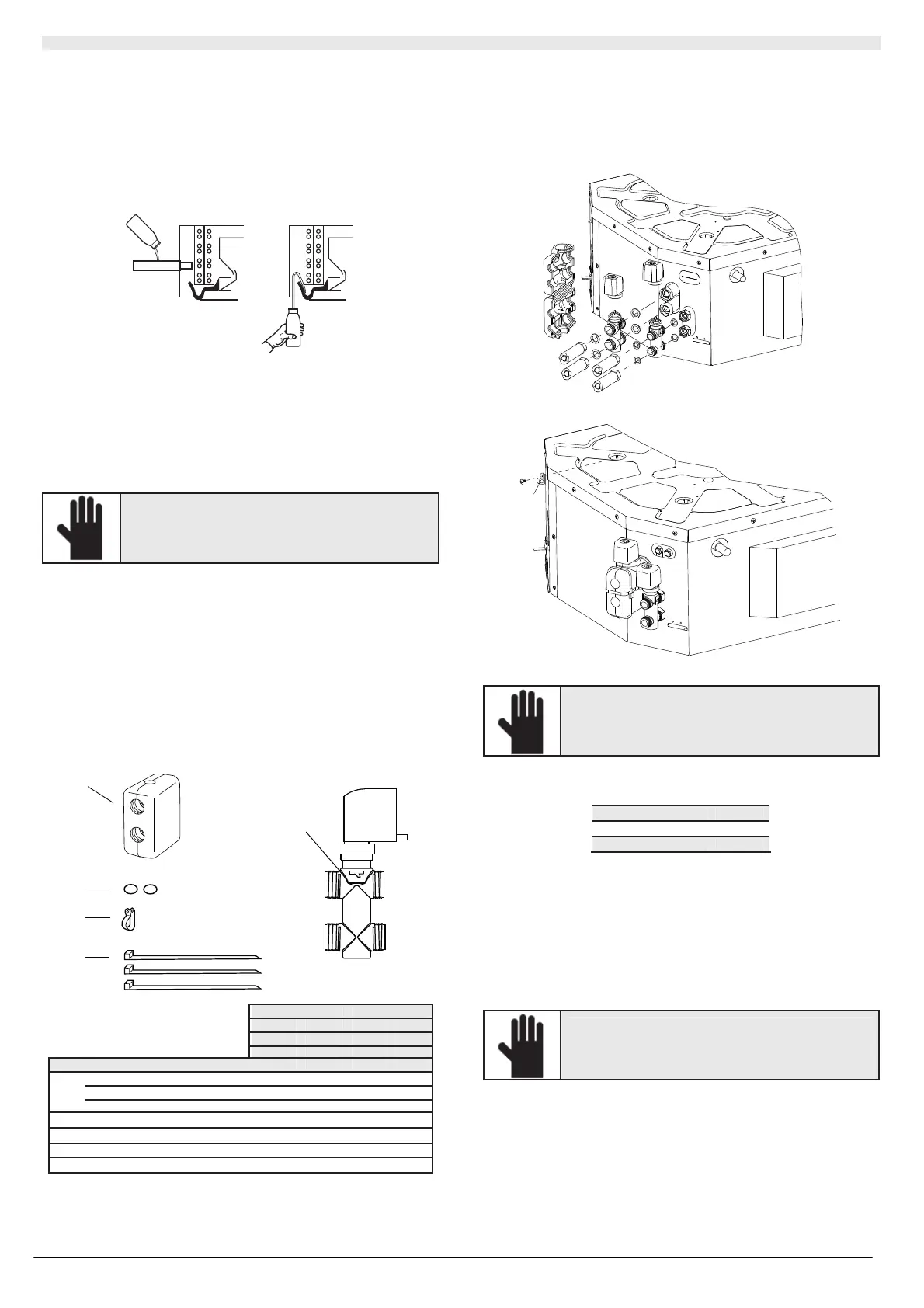

II.2.5.6 Instructions to install the motorised

electrothermal valve

The el ectrot hermal val ve u nit must be ass embled on to th e unit once

the l atter has been i nstalle d, following the di agrams and acc ording to

the model.

e

ATTENTION!

Lightly grease the O-Rings before placing them into

their se ats.

The val ve u nit f or a c old c oil mus t b e ins talled first in t he 4-pipe models.

Conn ect t he val ve unit to the coil and fast en it by ap plyi ng a t orq ue of:

Type of gasket Nm

Rubber 10/ 12

FabriFibra 25/ 30

Install t he act uat or on to the val ve b ody.

When c onn ecting t he s te el pipes o f th e s yst em, e nsure these are

alig ned a nd support ed s o as n ot t o exert abn ormal force on th e u nit.

When the system is filled with water, verify the tightness of all the

fittings. If the KVA accessory is pr esent, install the auxiliar y tray below

the val ve unit, inserting t he drain pipe int o t he rel ati ve hole; level and

fasten it t o the previously ass embled clip with the three screws

supplie d. I nsul ate th e t hree scre ws an d t he l ower b order of t he tr ay with

insulating material.

NOTE:

The tightness efficien c y of the v alve unit is fa ctor y-

test ed. An y lea ks in t he s yst em a re t her efore due to

an incorr ect in stall ation.

Cover th e val ve with t he shell (b), bloc king it wit h the cla mps (e) a nd

ensure th at all th e cold p arts are insula ted.

Fit the act uat or on the val ve b ody, route t he val ve c abl e thr ough t he box

and connec t it t o t he t ermi nal bl oc k as shown in fig . To co nnect t he

steel pipes to the s ystem, ens ure t he y are alig ned and su pported to

avoid e xcess s train on the u nit. I f the s yst em is filled wit h wat er, chec k

all fitting seals. Aft er ending t he hydraulic co nnec tions , ma ke sure ther e

are n o le a ks Ins ulat e t he val ve using the sh ell, fi x it b y means of t he

clips and ma ke sure tha t all c old parts are ins ulate d. F or 4-pip e hot

wat er, repeat all t he operations with gas a daptors, as p er the t able .

Loading...

Loading...