Technical description of the burner

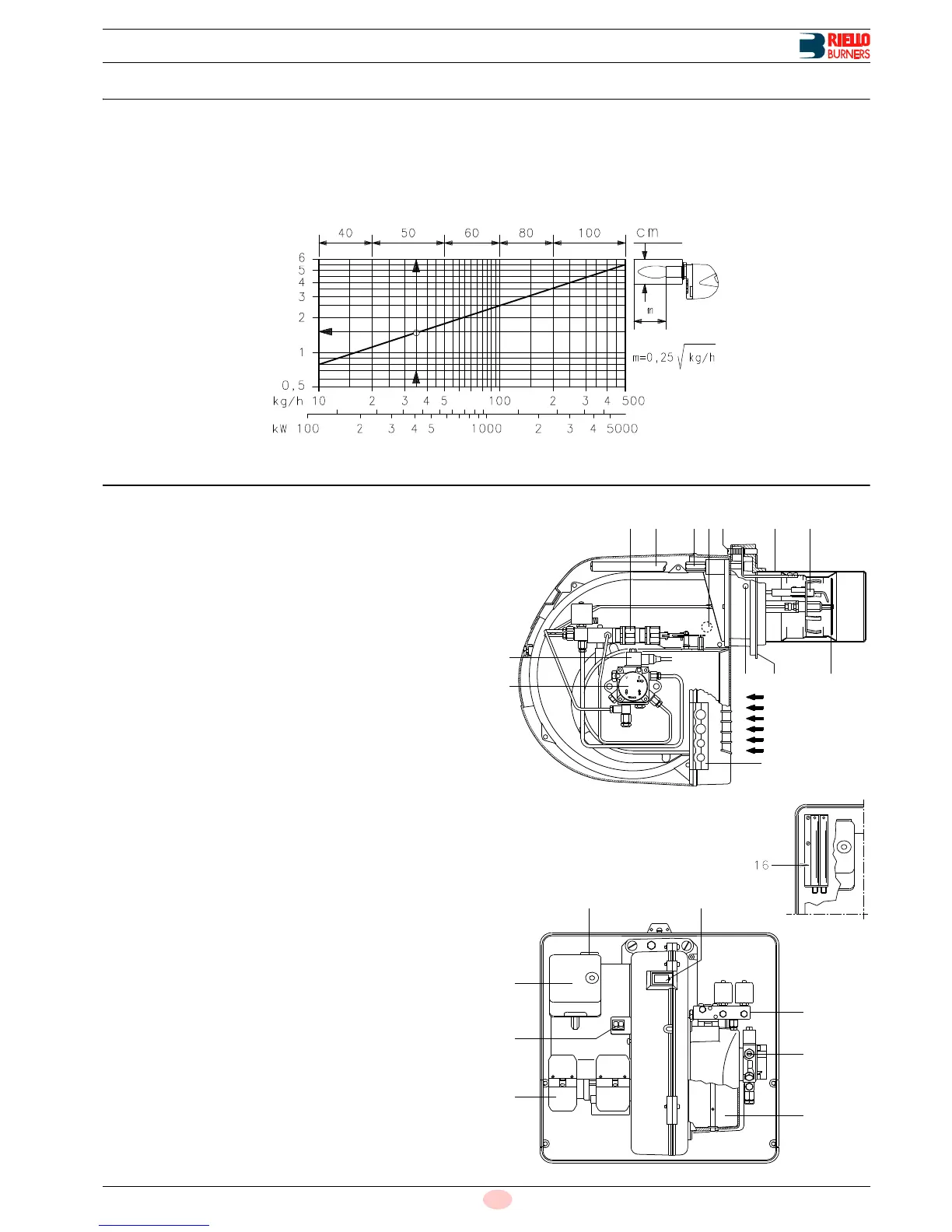

4.6 Test boiler

The firing rate was set in relation to special test boilers in accord-

ance with the methods defined in EN 267 standards.

Fig. 3 indicates the diameter and length of the test combustion

chamber.

Example

delivery 35 kg/hour: diameter = 50 cm; length = 1.5 m.

Whenever the burner is operated in a much smaller commercial-

ly-available combustion chamber, a preliminary test should be

performed.

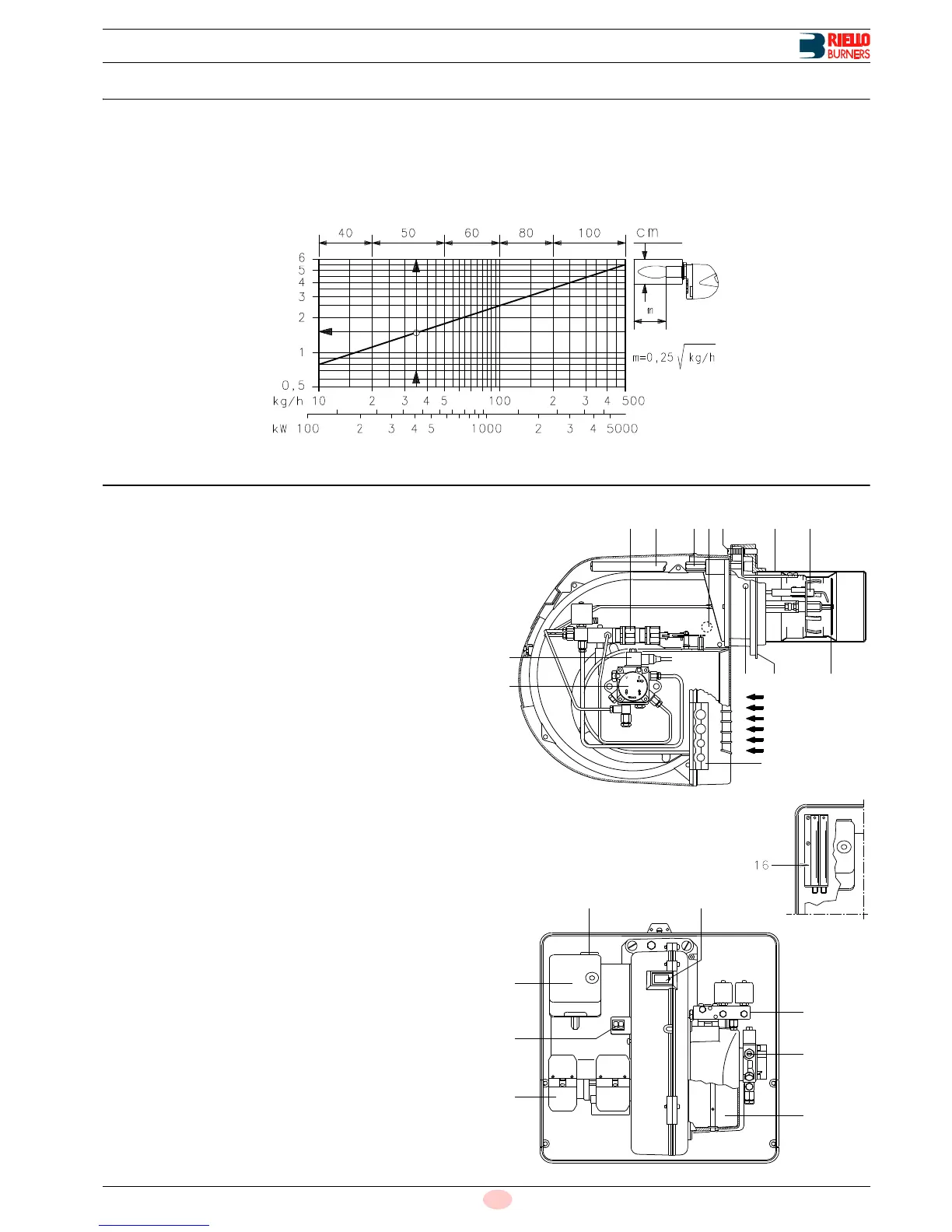

4.7 Burner description

1 Ignition electrodes

2 Combustion head

3 Screw for combustion head adjustment

4 Photocell for flame presence control

5 Screw for fixing fan to flange

6 Slide bars for opening the burner and inspecting the com-

bustion head

7 Hydraulic cylinder for regulation of the air gate valve in 1st

and 2nd stage positions. When the burner is not operating

the air gate valve is fully closed in order to reduce heat dis-

persion from the boiler due to the flue draught which draws

air from the fan suction inlet.

8 Safety solenoid valve

9Pump

10 Plate prearranged to drill 4 holes for the passage of hoses

and electrical cables.

11 Air inlet to fan

12 Fan pressure test point

13 Boiler mounting flange

14 Flame stability disk

15 Flame inspection window

16 Extensions for slide bars 6)

17 Motor contactor and thermal cut-out reset button

18 Control box with lock-out pilot light and lock-out reset button

19 Two switches:

- one “burner off - on”

- one for “1st - 2nd stage operation”

20 Plugs for electrical connections

21 Air gate valve

22 Pump pressure adjustment

23 1st and 2nd stage valve assembly

Two types of burner failure may occur:

Control box lock-out

if the control box 18)(Fig. 4) pushbutton (red led) lights up, it

indicates that the burner is in lock-out. To reset, hold the

pushbutton down for between 1 and 3 seconds.

Motor trip

pressing the pushbutton on thermal cutout 17)(Fig. 4).

Loading...

Loading...