Installation

5.9 Nozzle installation

5.9.1 Choice of nozzles for 1st and 2nd stage

The burner complies with the emission requirements of the

EN 267 standard.

In order to guarantee that emissions do not vary, recommended

and/or alternative nozzles specified by Riello in the Instruction

and warning booklet should be used.

Both nozzles must be chosen from among those listed in Tab. E

and Tab. F.

The first nozzle determines the delivery of the burner in the 1st

stage.

The second nozzle works together with the 1st nozzle to deter-

mine the delivery of the burner in the 2nd stage.

The deliveries of the 1st and 2nd stages must be contained within

the value range indicated on page 2. Use nozzles with a 60°

spray angle at the recommended pressure.

The two nozzles usually have equal deliveries, but the 1st stage

nozzle may have the following specifications if required:

a delivery less than 50% of the total delivery whenever the

back-pressure peak must be reduced at the moment of fir-

ing;

a delivery higher than 50% of the total delivery whenever the

combustion during the 1st stage must be improved.

Example

(gas oil):

Boiler output = 270 kW - efficiency 90%

Output required by the burner =

270 : 0.9 = 300 kW

300 : 2 = 150 kW per nozzle

therefore, two equal, 60°, 12 bar nozzles are required:

1° = 3.00 GPH - 2° = 3.00 GPH,

or the following two different nozzles:

1° = 2.50 GPH - 2° = 3.50 GPH,

or:

1° = 3.50 GPH - 2° = 2.50 GPH.

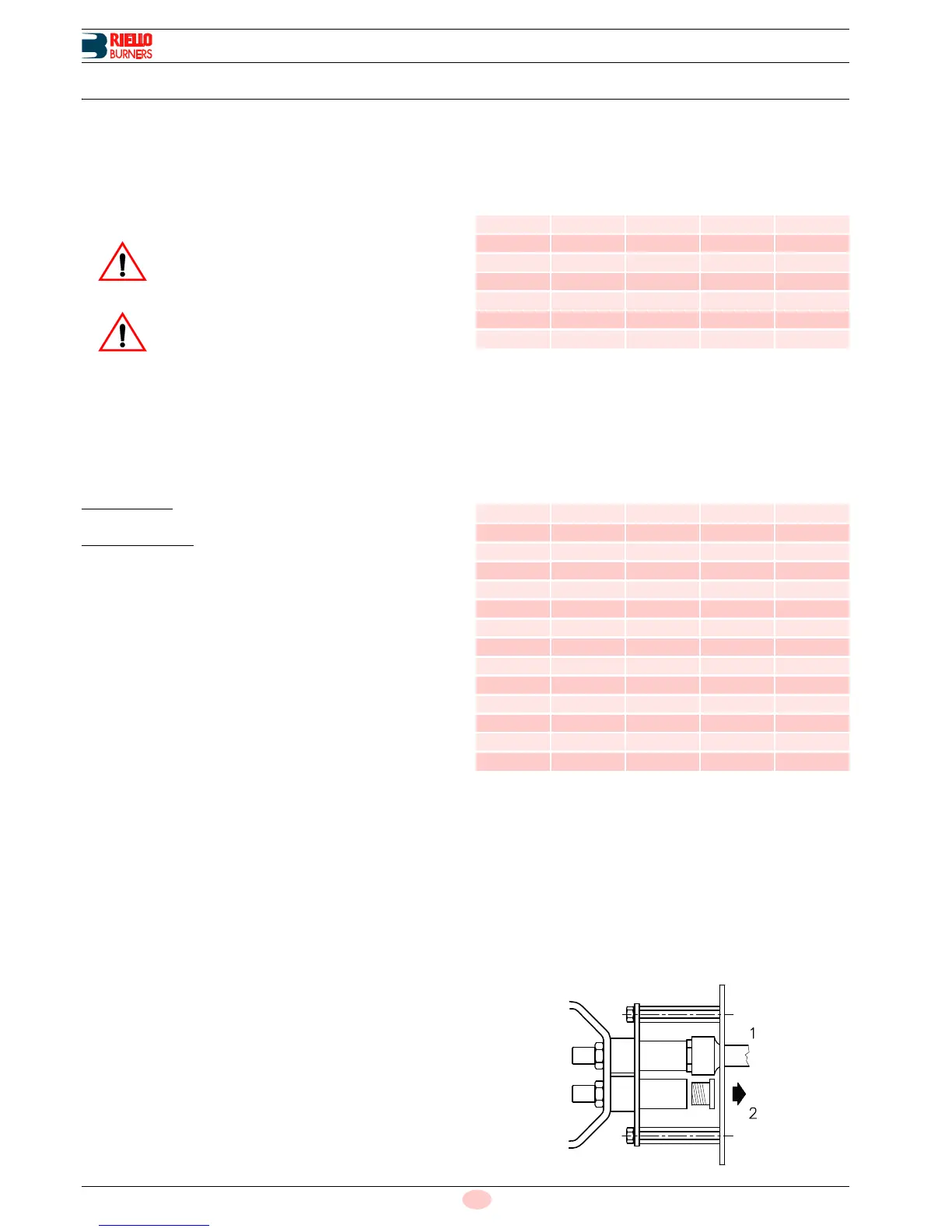

5.9.2 Tables nozzles

(Gas oil 100%)

Tab. E

(1)

We get the indicated delivery when both nozzles are working

and gas oil has the following characteristics: density 0.84 kg/

dm

3

- viscosity 4.2 cSt/20 °C - temperature 10 °C.

(Kerosene 100%)

Tab. F

(1)

We get the indicated delivery when both nozzles are working

and kerosene has the following characteristics: density 0.81

kg/dm

3

- viscosity 1.6 cSt/20 °C - temperature 25 °C.

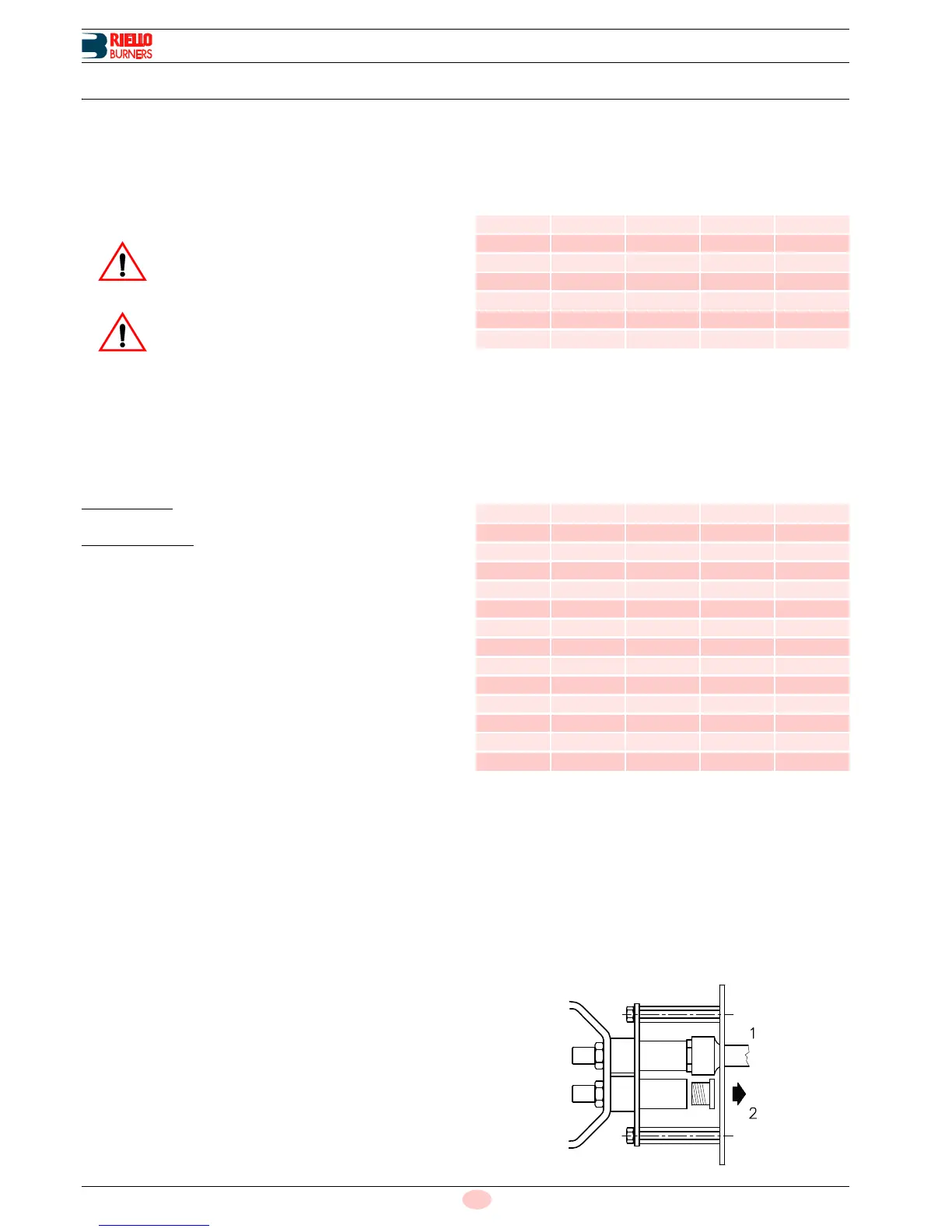

5.9.3 Nozzle assembly

At this stage of installation the burner is still disassembled from

the blast tube; it is therefore possible to fit two nozzles with the

box spanner 1)(Fig. 11) (16 mm), after having removed the plas-

tic plugs 2), fitting the spanner through the central hole in the

flame stability disk.

The use of nozzles other than those specified by

Riello S.p.A. and inadequate regular maintenance

may result into emission limits non-conforming to

the values set forth by the regulations in force, and

in extremely serious cases, into potential hazards

to people and objects.

The manufacturing company shall not be liable for

any such damage arising from nonobservance of

the requirements contained in this manual.

GPH

kg/h

(1)

kW

12 bar

10 bar 12 bar 14 bar

3.00 11.5 12.7 13.8 150.6

3.50 13.5 14.8 16.1 175.5

4.00 15.4 17.0 18.4 201.6

4.50 17.3 19.1 20.7 226.5

5.00 19.2 21.2 23.0 251.4

5.50 21.1 23.3 25.3 276.3

6.00 23.1 25.5 27.7 302.4

GPH

kg/h

(1)

kW

10 bar

8 bar 9 bar 10 bar

2.50 7.31 7.79 8.25 99.0

2.75 8.04 8.57 9.07 108.6

3.00 8.77 9.35 9.90 118.6

3.25 9.51 10.13 10.72 128.4

3.50 10.24 10.91 11.55 138.3

4.00 11.70 12.47 13.20 158.0

4.50 13.16 14.03 14.85 177.8

5.00 14.62 15.58 16.50 197.8

5.50 16.09 17.14 18.15 217.4

6.00 17.55 18.70 19.80 237.1

6.50 19.01 20.26 21.44 256.8

7.00 20.47 21.82 23.09 276.5

7.50 21.94 23.38 24.74 296.3

8.00 23.40 24.93 26.39 316

Loading...

Loading...