Continuous ow internal ueing guide: 11748-D 04-13 | 5

Flue gases can reach temperatures up to 200 °C. The flue

terminal is to terminate in a location so as not to cause a

nuisance, in accordance with AS/NZS 5601.

Flueing guidelines

Flue support

Ensure the flue is fully

supported independently of

the appliance by use of suitable

clips or brackets, in accordance

with AS/NZS 5601. Appropriate

standoff brackets are supplied

with each FFSSROOFCOWL and

FFSSPIPE1000.

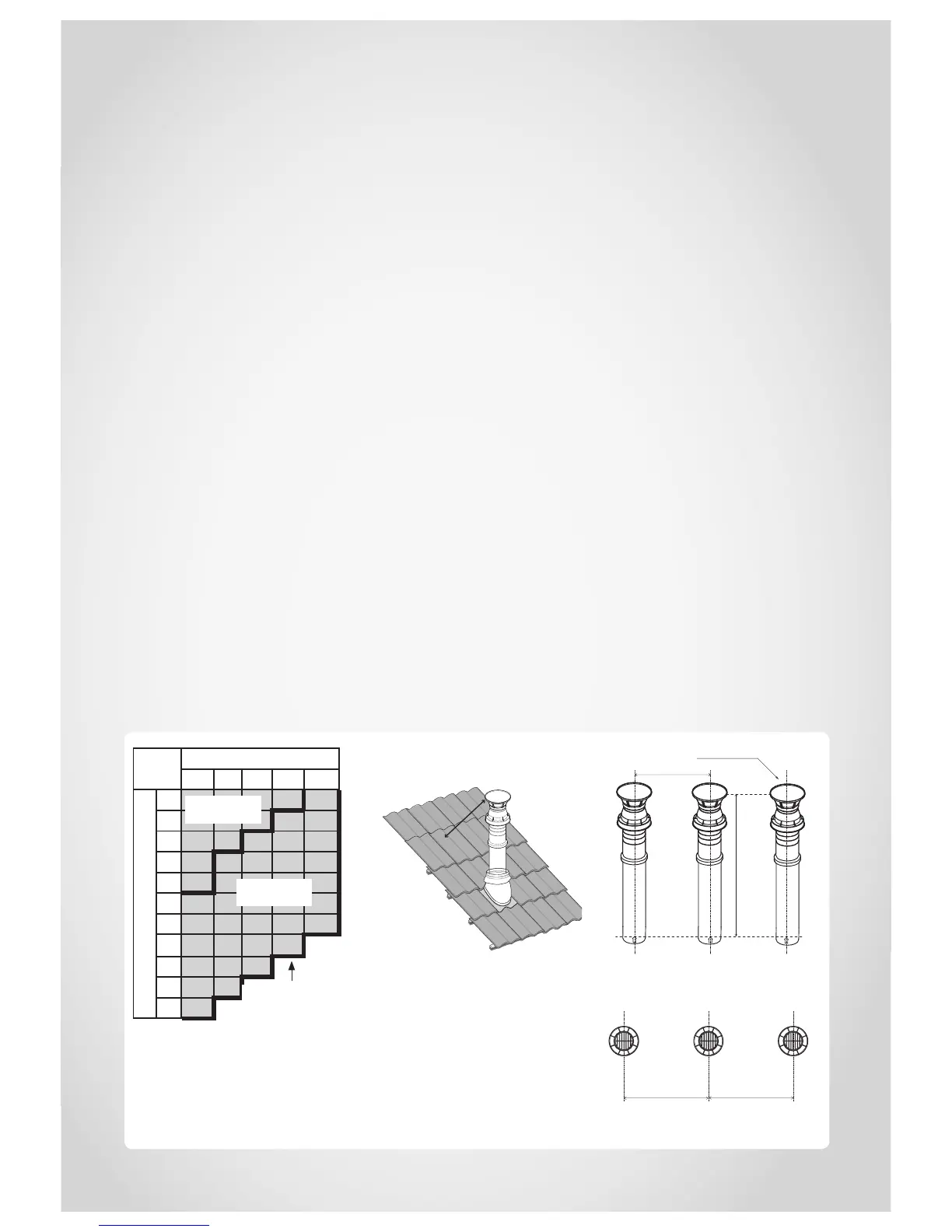

Flue length

The chart highlights the

maximum flue length and

number of bends. It also shows

the difference between a short

and long flue.

For flues over 2 m there is a

DIP switch change required—

refer commissioning checklist

supplied with the appliance.

This increases the combustion

speed to overcome the

additional friction loses.

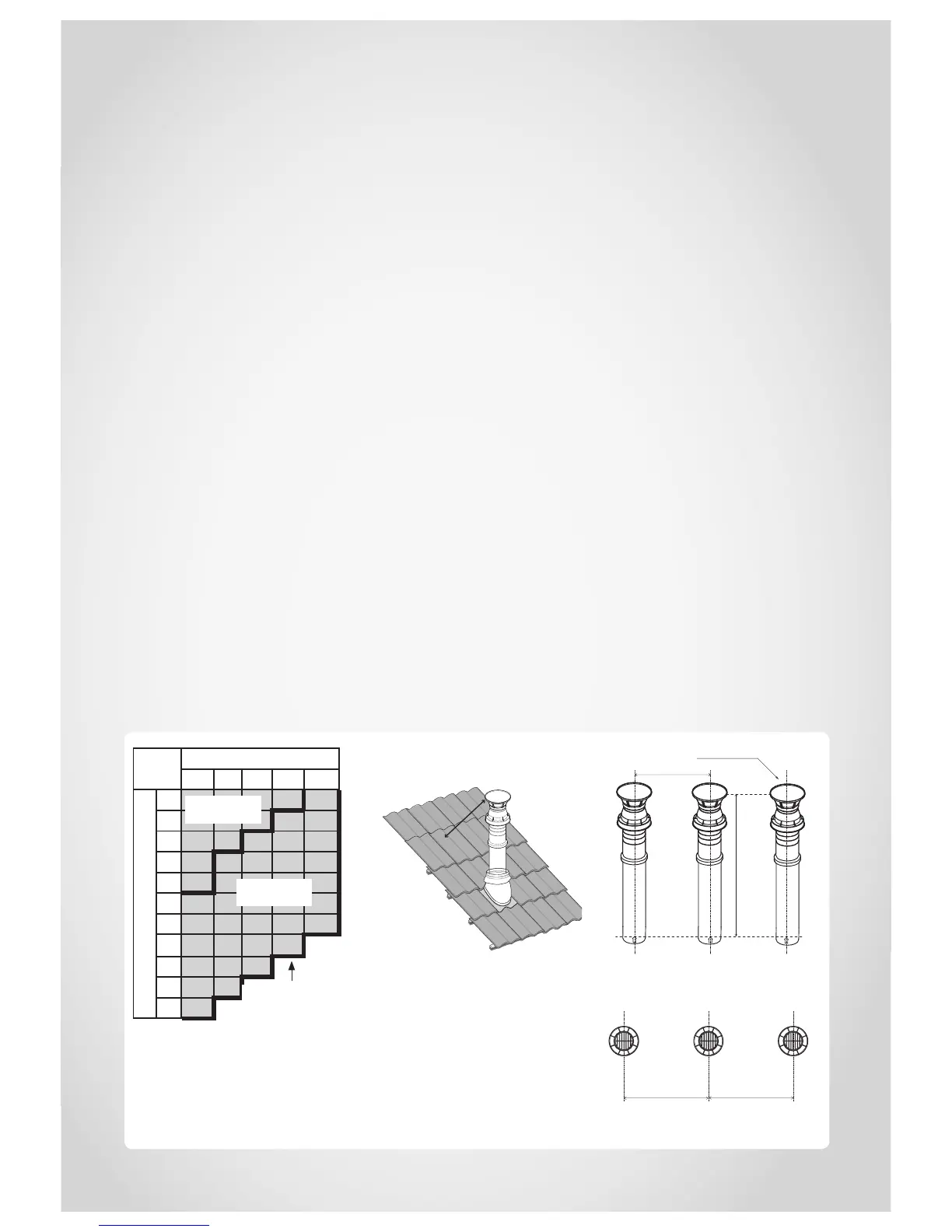

Vertical terminations.

To ensure products of

combustion are cleared,

adequate clearance from the

building is required.

The flue cowl should have a

500 mm clearance from any

part of the building. This also

applies to steeped and pitched

roofs, which should be clear of

the ridge line.

Lesser clearances may provide

perfectly adequate flue systems

depending on the installation.

Minimum clearances are shown

in AS/NZS 5601.

Multiple flues

Ensure minimum distances, as

shown are maintained.

Each terminal is to be

terminated at the same vertical

height.

Number of 90 ° Bends

0 1 2 3 4

Flue Length (m)

1

2

3

4

5

6

7

9

11

13

15

Short flue

setting

Long flue

setting

Max. flue length

Min. clearance 500 mm to

nearest part of roof

Min. 350 mm

Min. clearance 500 mm

Roof cowl

Min. 350 mm Min. 350 mm

Flue length table

Vertical terminal clearance

Multiple flues - vertical flue clearance

Multiple flues - horizontal flue

clearance

Loading...

Loading...