Linear ue installation guide 13541-A 01-20 | 15

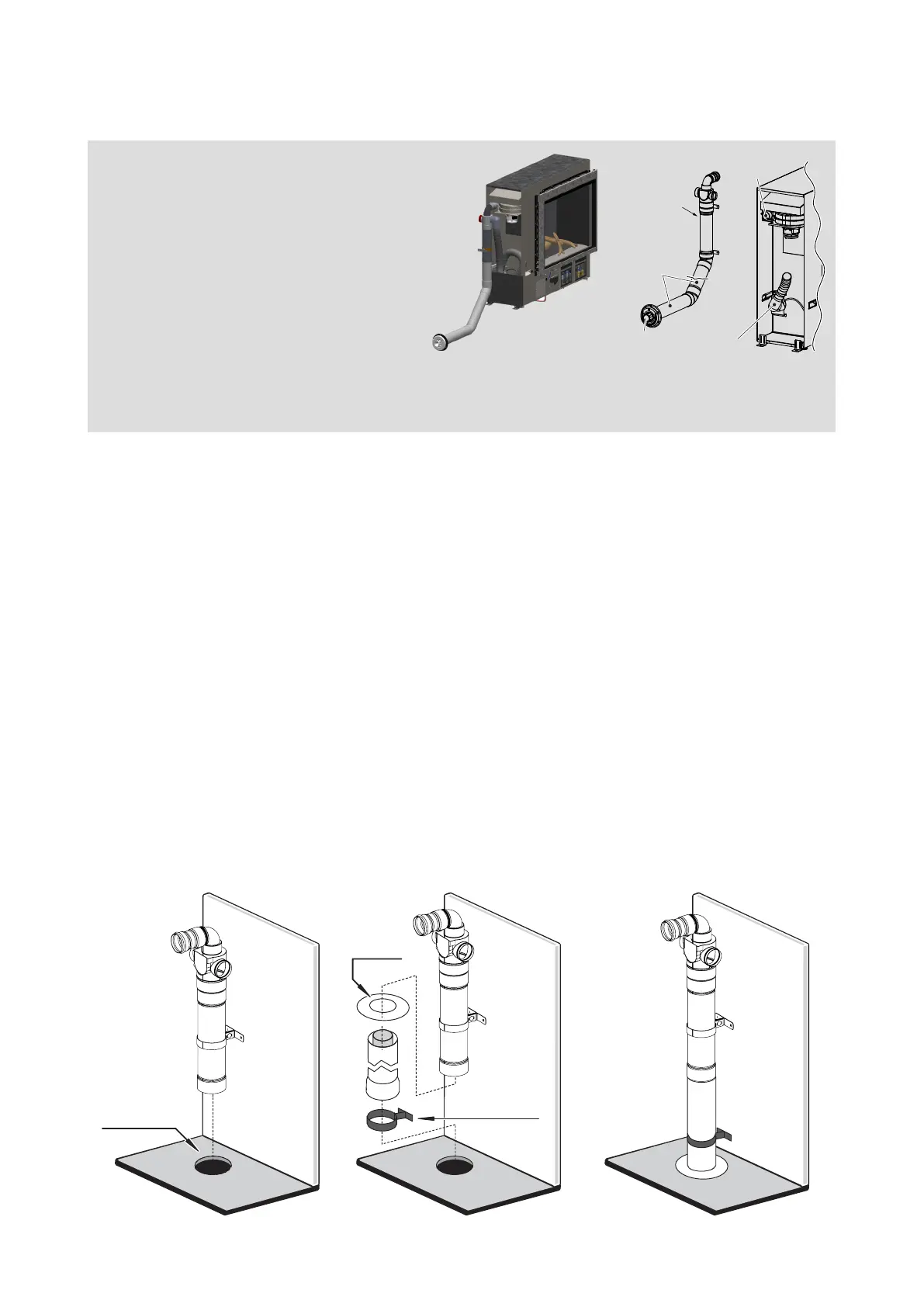

Down and out ue assembly

I

n

t

e

r

i

o

r

wa

l

l

I

n

te

ri

o

r

wa

l

l

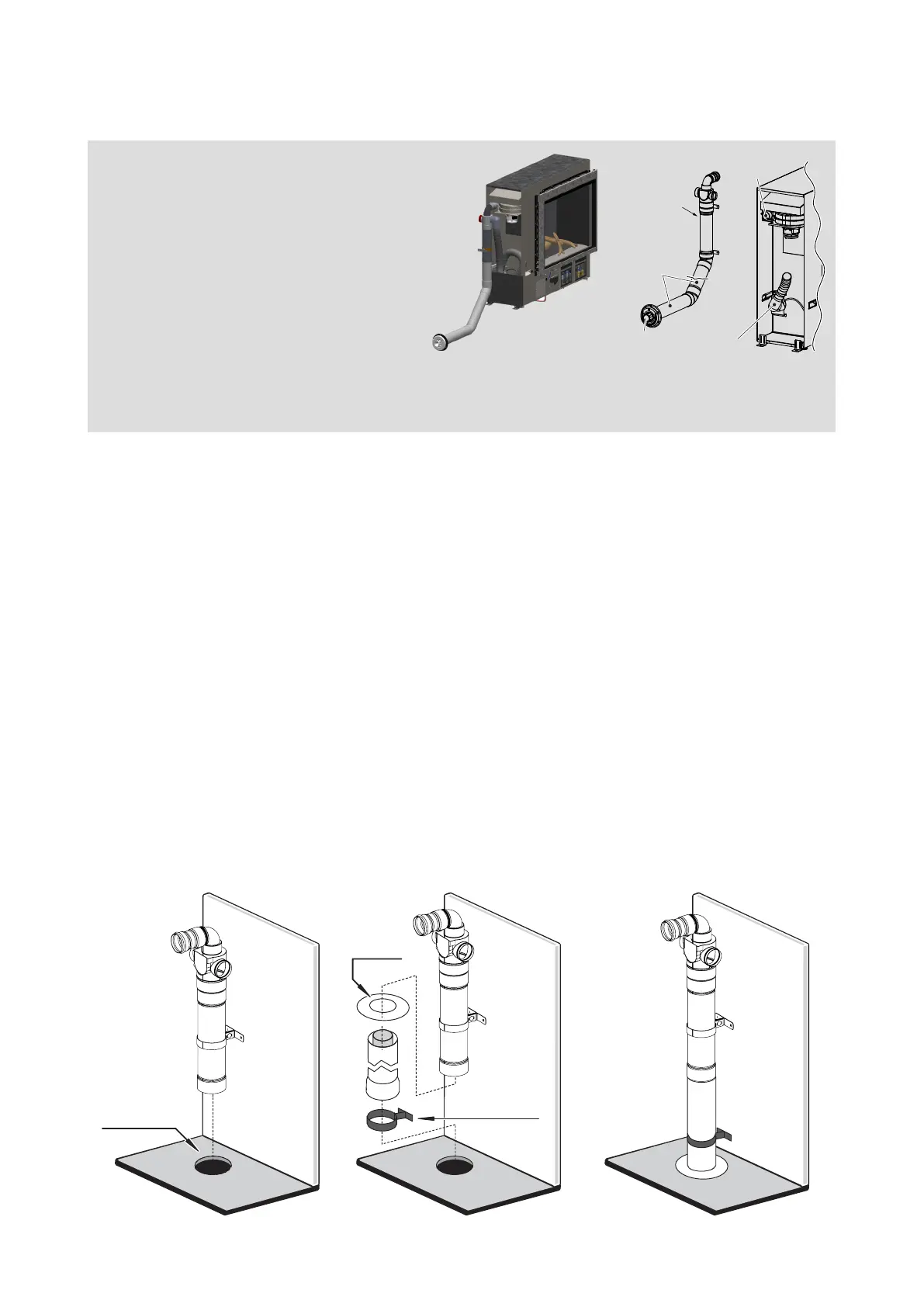

Wall plate

Stand off clip

I

n

t

e

r

i

o

r

w

a

l

l

Floor penetration

Air inlet pipe

Flue exhaust

outlet

ESWTERM

ESPIPE900

LSFKIT01

The down and out ue allows for

the adaption ue component to face

downwards, and for the ue to run

vertically through a hole in the oor, and

then terminate horizontally outside—ue

must terminate 300 mm above the ground.

With the Linear installed into the support framing:

1. Fit the ue components and lengths of ue pipe as required. Ensure the ue transition

section of the LSFKIT01 is included. NEVER discard this section as this will cause an unsafe

installation due to a buildup of heat in the ue.

2. The ue penetration should be made at the same time as the cutout for the gas connection.

The oor penetration minimum diameter is 80 mm to non-combustible surfaces such as brick,

and 100 mm to combustible surfaces such as plaster.

3. Pass the ue pipe through the internal wall plate and through the oor penetration, and secure

the wall plate in place to seal the oor.

4. Prepare the horizontal section of the ue system under the oor by connecting the ue pipe

and bends as required. Allow for a 2° continuous fall from the rst section of the horizontal ue

pipe to the wall penetration.

5. Create the wall terminal, refer p.17, ensuring a 300 mm clearance between the ue terminal

and ground level.

A minimum of 300 mm of straight ue before any bends. This is required due to the heat

produced from the initial section of ue, which could melt the outer plastic. The LSFKIT01 has

the 300 mm min. ue length built in.

Loading...

Loading...