6 Operation

Rittal air/water heat exchanger assembly instructions 21

EN

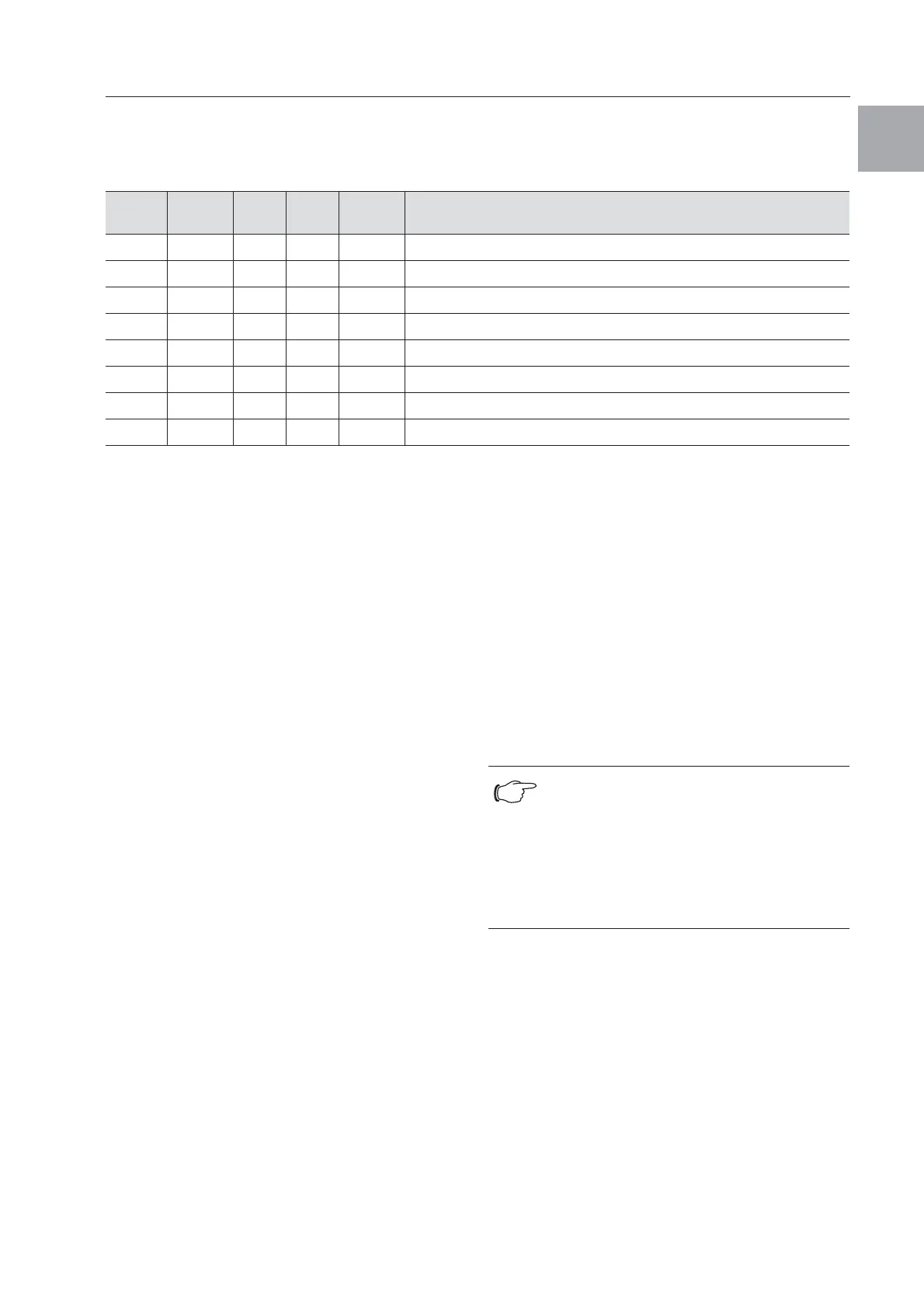

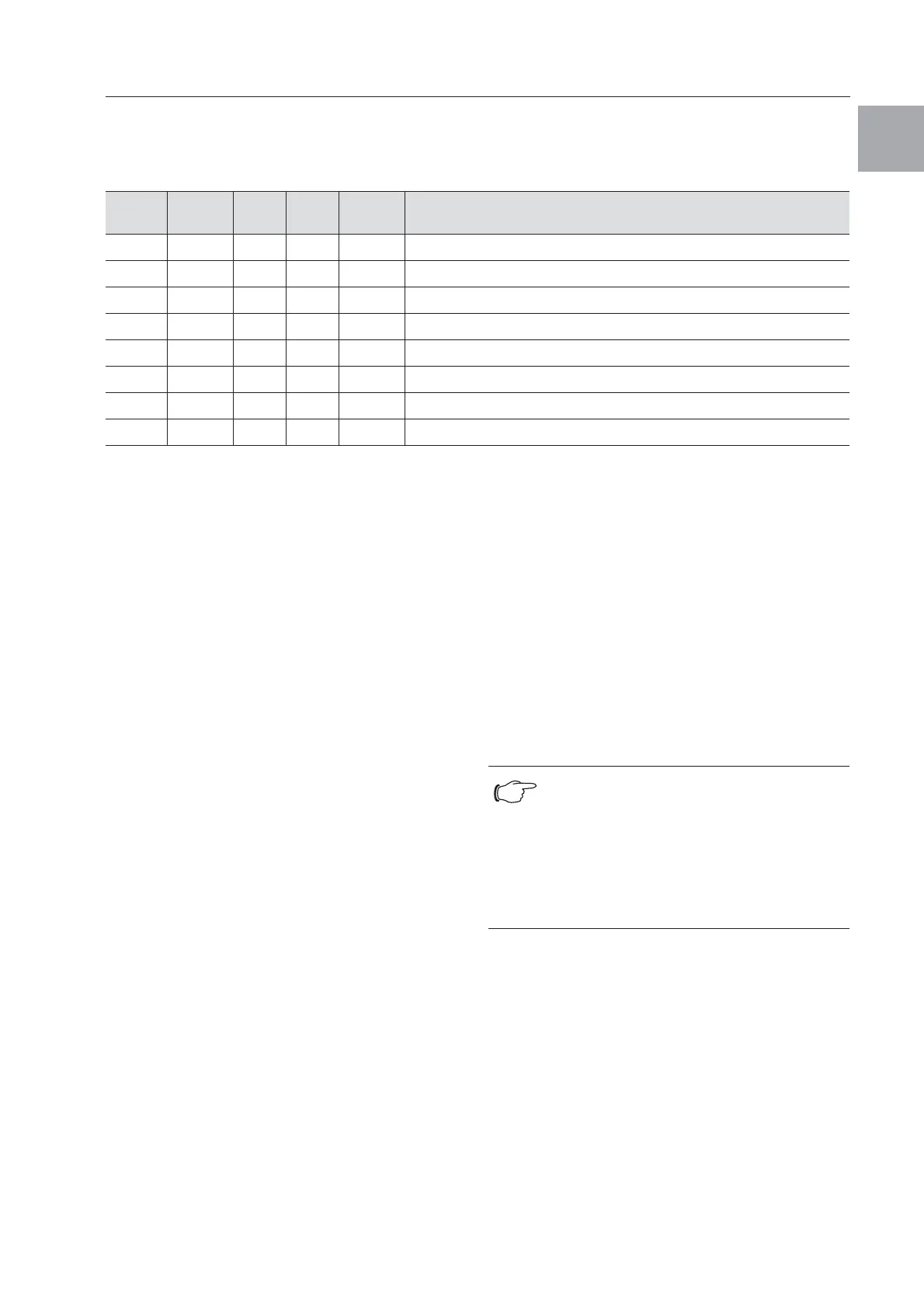

6.2.8 Defining system messages for evaluation

System messages are shown on the display screen

of the e-Comfort controller via the displays A01 to

A20 and E0.

A more detailed explanation of the system messages

may be found in section “6.2.10 Evaluating system

messages”, page 22. See also fig. 25 on page 20.

Tab. 9: System messages which may be evaluated via relays

The system messages A01 – A20 may additionally

be evaluated via two floating system message

relays. In this way, one of the two system message

relays may be allocated to each system message.

System message relays with normally open contact,

see wiring diagrams at section “4.6.5 Installing the

power supply”, page 11:

– Terminal 3: NO (normally open, relay 2)

– Terminal 4: Connection of the supply voltage to the

system message relay

– Terminal 5: NO (normally open, relay 1)

The definition NO refers to the de-energised state.

As soon as power is applied to the air/water heat

exchanger, both system message relays (relay 1

and 2) energise.

This is the normal operating state of the air/water

heat exchanger.

As soon as a system message occurs or the power

supply is interrupted, the corresponding relay will

drop out and open the contact.

Program system messages with the value

0: System message is not sent to the system

message relays, but merely appears in the

display

1: System message is evaluated by relay 1

2: System message is evaluated by relay 2

3: System message is neither sent to the system

message relay, nor does it appear in the display

(setting can only be made using RiDiag soft-

ware)

6.2.9 Setting the master-slave identifier

When several air/water heat exchangers are con-

nected together (maximum 10), one of the air/water

heat exchangers must be defined as the “master”

and the others as “slaves”. For this purpose, assign

a corresponding identifier (address) to each air/

water heat exchanger which will enable the air/water

heat exchanger to be identified in the network.

If one of the slave units reaches the set temperature

or if the door limit switch function is activated, the

affected slave unit will report to the master unit,

which then deactivates all the other air/water heat

exchangers.

Progr.

level

Display

screen

Min.

value

Max.

value

Factory

setting

Type or location of fault

7 A01 0 2 0 Enclosure door open

8 A02 0 2 0 Internal temperature of enclosure too high

9 A08 0 2 1 Condensate warning

10 A10 0 2 1 Fan blocked or defective

11 A16 0 2 1 Internal temperature sensor

12 A18 0 2 1 EPROM

13 A19 0 2 0 LAN/Master-Slave

14 A20 0 2 0 Voltage drop

Notes:

– Only one unit may be configured as

master, and its identifier must match

the number of connected slave units.

– The slave units must have different

identifiers.

– The identifiers must be numbered in

ascending order without any gaps.

Loading...

Loading...