6.2 Safety Equipment

The cooling circuit of the cooling unit embodies a component tested high-pressure monitor to VBG

20.7.1 which is set to maximum operating pressure and operates via an automatic reset device at

recurring pressure drop. Temperature and low-pressure monitoring will prevent the evaporator from

icing up. If there is a risk of icing up, the condenser is switched off and automatically switched on

again at higher temperatures. The coolant compressor and the fans are equipped with thermal

winding protection against excess current and excess temperature.

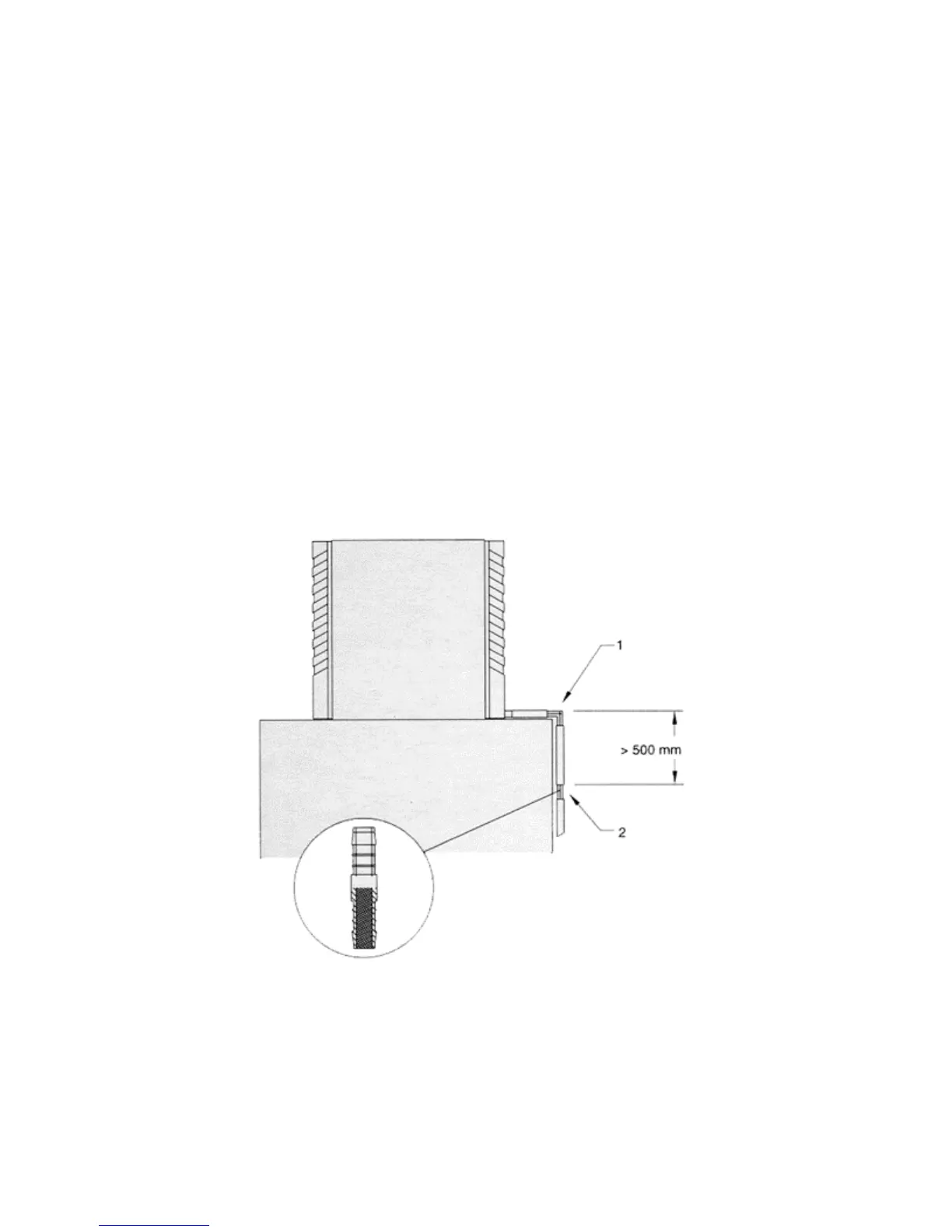

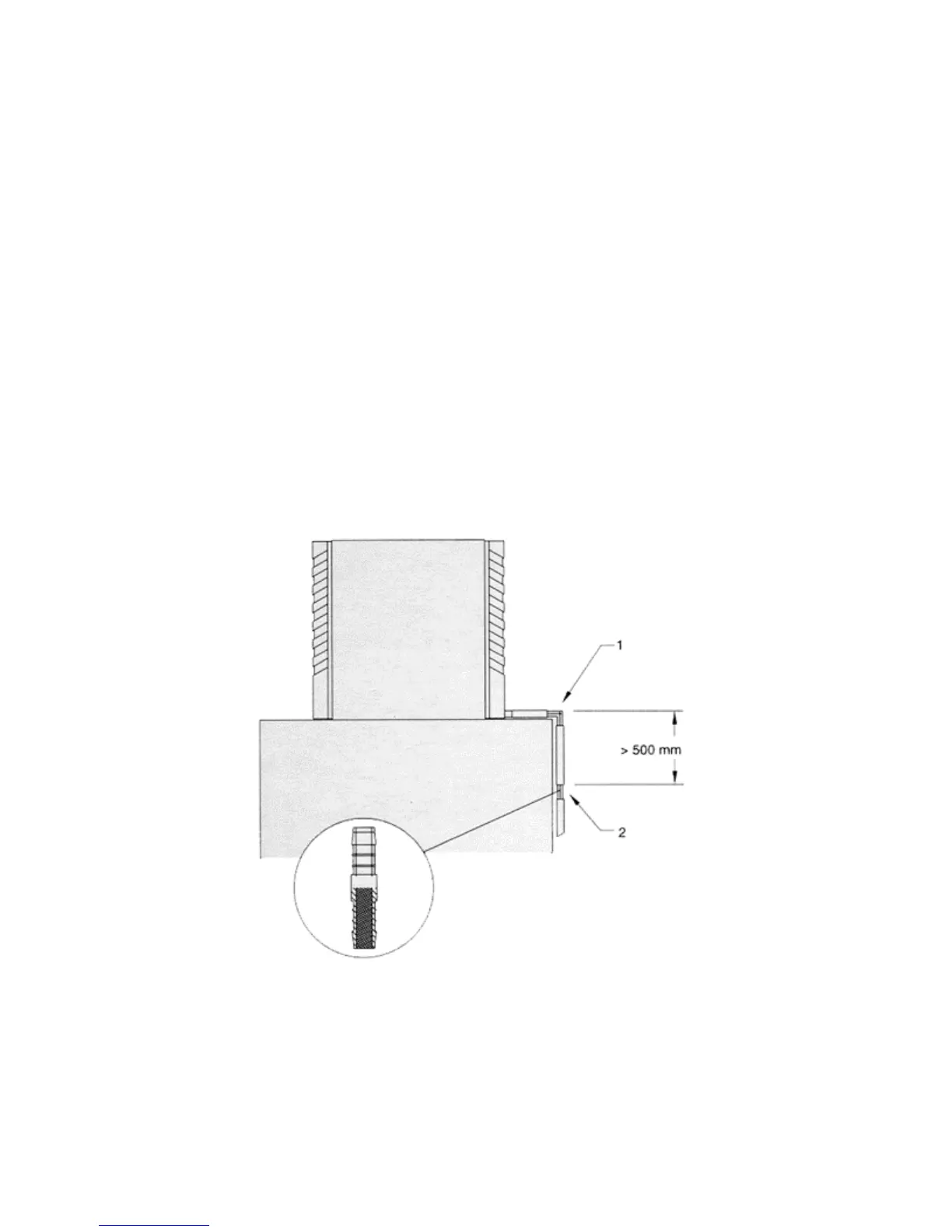

6.3 Condensate Discharge

1. To drain away any incidental condensate, attach a discharge hose to the 12 mm by SK

3296100/3296500/3272100 and 15 mm by SK 3290100/3290500/3280100 pipe connection piece,

which protrudes from the unit.

Connect the drain hose to the angled connection piece (1) (avoiding any kinks) and route the hose

directly downwards in order to prevent any backflow and overflow of the condensate inside the unit.

2. To prevent external air flowing through the condensate discharge connection piece into the interior

of the enclosure, fir the enclosed backflow preventer (2) in the drain hose.

The nonwoven fabric inserted in the backflow preventer ensures safe drainage of the condensate.

The backflow preventer may become contaminated over a period of time and should be examined at

least once per annum and replaced as necessary.

Loading...

Loading...