11.3 Measuring Water in Hydraulic and Lubricating Fluids

From North Notts Fluid Power Centre

In mineral oils and non-aqueous fire resistant fluids water is undesirable. Mineral oil usually has a water content

of 50-300 ppm which it can support without adverse consequences.

Once the water content exceeds about 500ppm the oil starts to appear hazy. Above this level there is a danger of

free water accumulating in the system in areas of low flow. This can lead to corrosion and accelerated wear.

Similarly, fire resistant fluids have a natural water content which may be different to mineral oils.

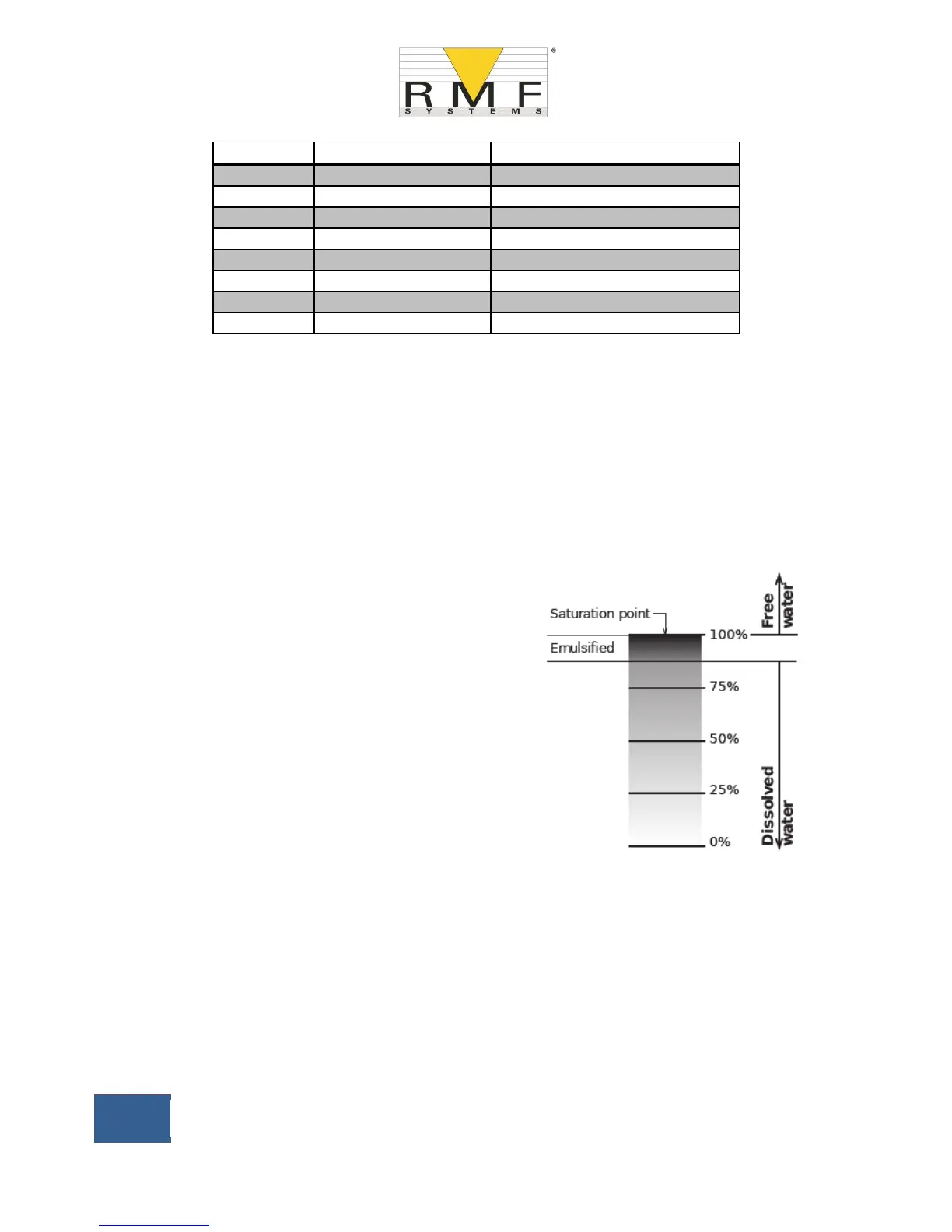

Saturation Levels

Since the effects of free (also emulsified) water are more harmful than

those of dissolved water, water levels should remain well below the

saturation point.

However, even water in solution can cause damage and therefore

every reasonable effort should be made to keep saturation levels as

low as possible. There is no such thing as too little water. As a

guideline, we recommend maintaining saturation levels below 50%

in all equipment.

Loading...

Loading...