201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.11 Differential Pressure vs Fluid Viscosity, for various flow rates

6.1.3.2 Manual Flow Control

Another possibility is to fit a simple manual flow control (flow restrictor) to the outlet of the CMS.

− This should only be done where the available pressure is less than twice the maximum value calculated. This

is because the small orifice size needed to control the flow from a pressure larger than this has a risk of

blockage.

− The flow controller must be fitted to the outlet only. If fitted to the inlet it will have a filtering effect.

− The flow controller must be fitted directly to the CMS outlet port.

6.1.3.3 Active Flow Control

This is only needed for operation at high differential pressures, where a too-high flow would otherwise be

generated.

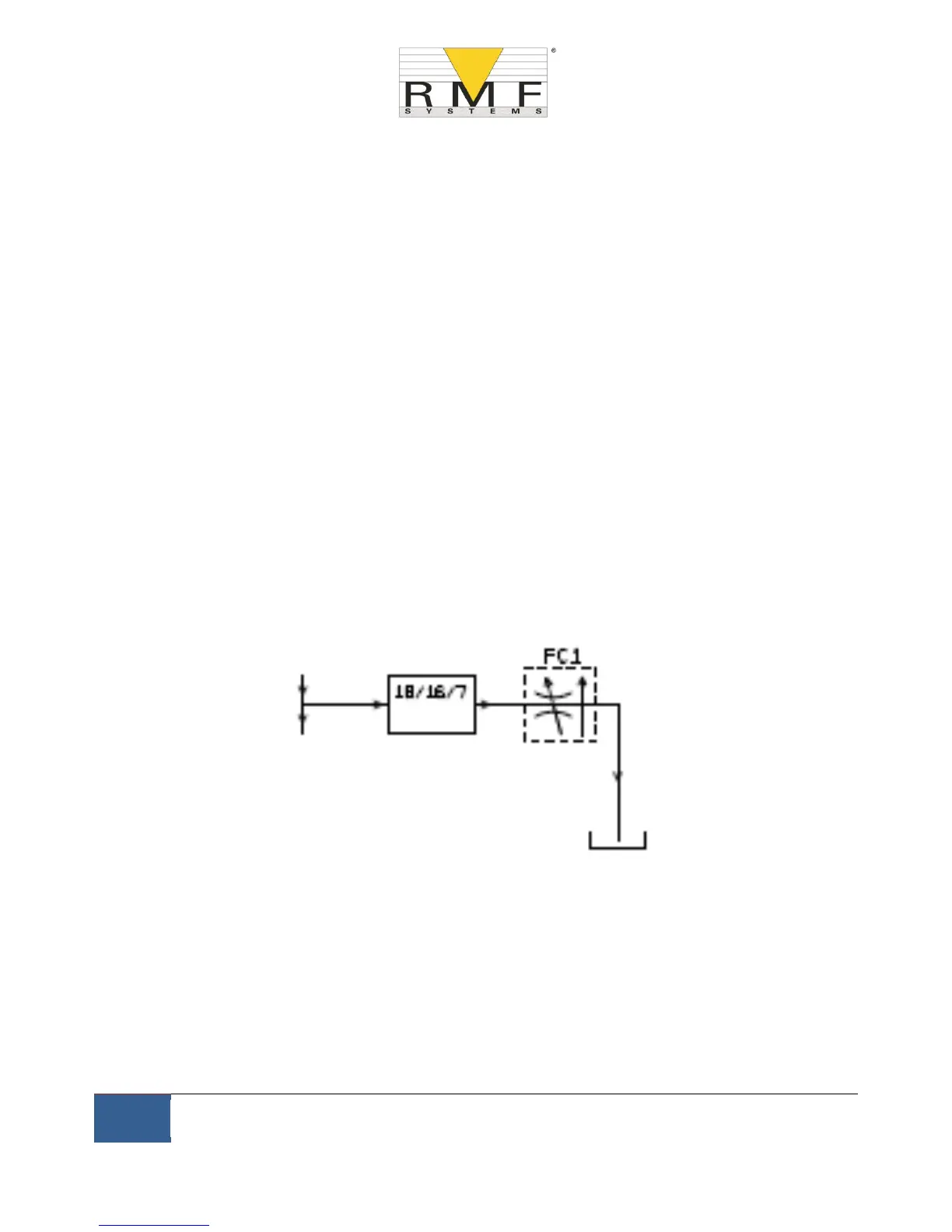

A pressure compensated flow control valve is fitted to the CMS drain outlet. This has the effect of a ``flow

limiter’’, maintaining a constant flow rate even with a varying inlet pressure (provided this pressure stays above a

minimum working value). Below this pressure the valve is wide open so has little effect, i.e. the flow will be less

than the 200ml/min controlled value. This ``minimum working value’’ will be typically 5-10 bar but will vary with

viscosity. For these lower pressures a flow control valve is not needed and other methods are better used to

control flow as previously described.

Figure 6.12 CMS flow actively regulated

6.2 General Operation

6.2.1 Physical Checks

• Oil leaks on and around the unit

• Fatigue in hoses and pipework that might then leak when under system pressure

Loading...

Loading...