As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Microscope counting examines the particles differently to APCs and the code is given with two scale numbers

only. These are at 5μm and 15μm equivalent to the 6μm(c) and 14μm(c) of the APCs (Figure 11.2)

11.5 NAS1638 Cleanliness Code System (now defunct, replaced by SAE AS4059E Table

1)

The NAS system was originally developed in 1964 to define contamination classes for the contamination

contained within aircraft components. The application of this standard was extended to industrial hydraulic

systems simply because nothing else existed at the time. The coding system defines the maximum numbers

permitted of 100ml volume at various size intervals (differential counts) rather than using cumulative counts as in

ISO 4406:1999. Although there is no guidance given in the standard on how to quote the levels, most industrial

users quote a single code which is the highest recorded in all sizes and this convention is used on the CMS

software.

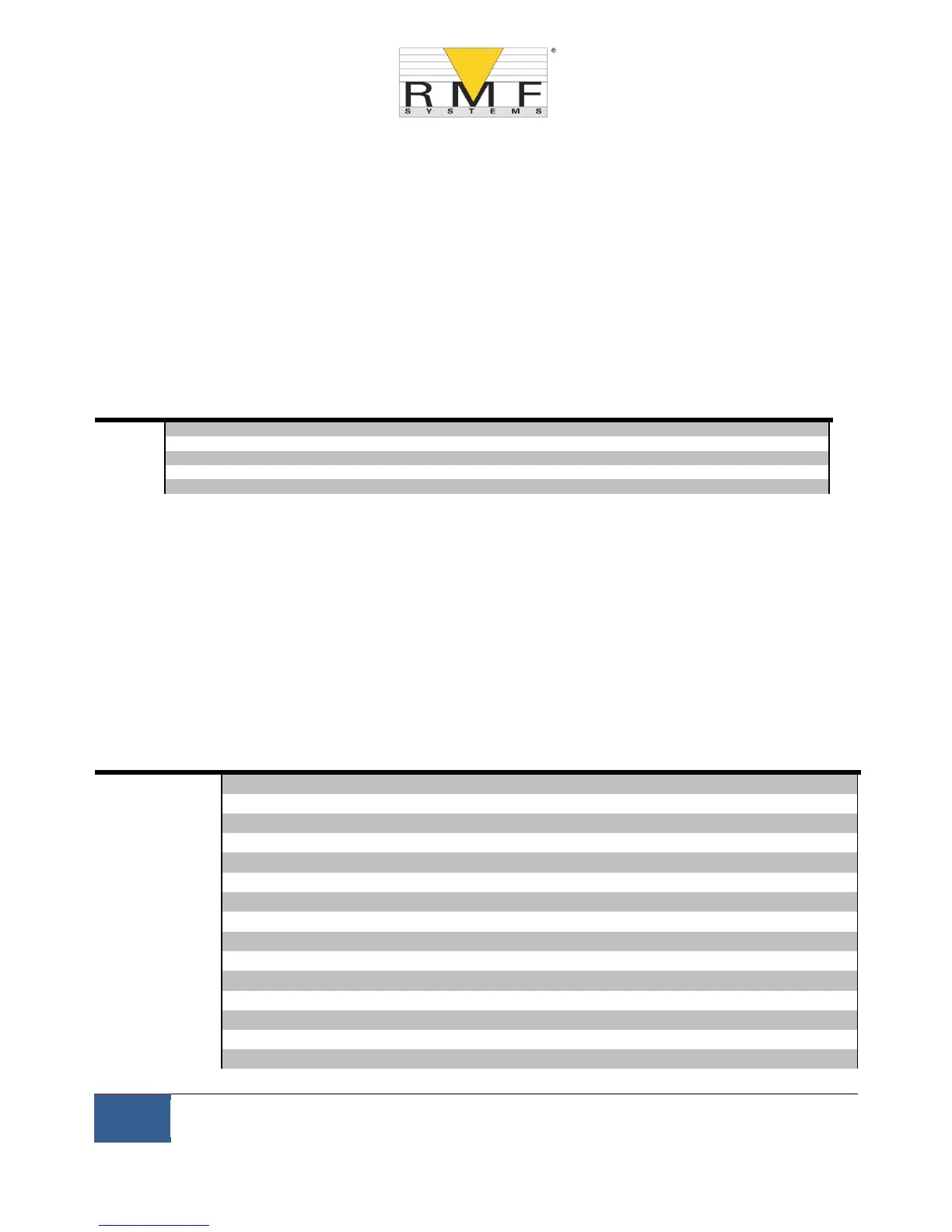

Table 11.1 Contamination Level Classes according to NAS1638 (January 1964)

The contamination classes are defined by a number (from 00 to 12) which indicates the maximum number of

particles per 100 ml, counted on a differential basis, in a given size bracket.

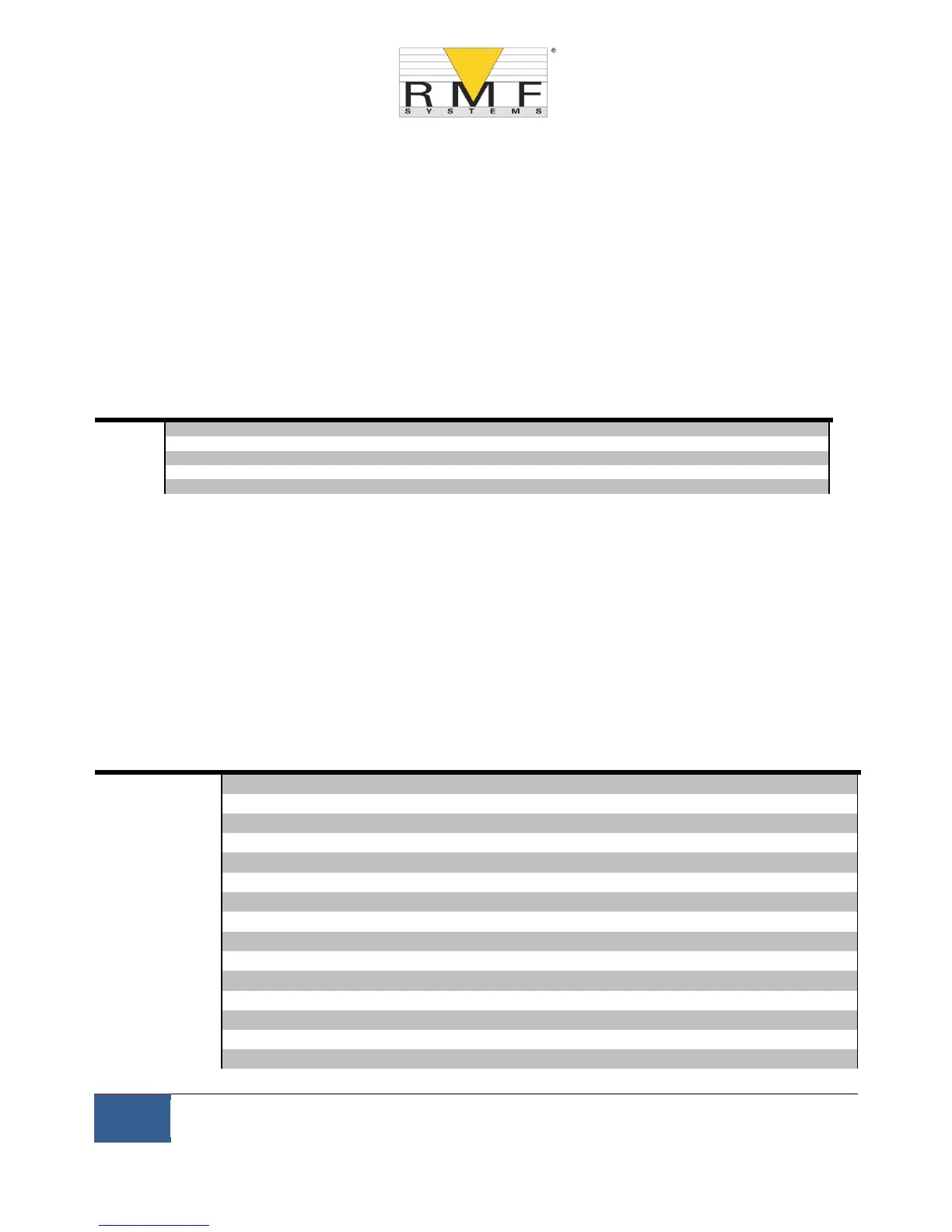

11.6 SAE AS4059 REV E Cleanliness Classification for Hydraulic fluids

This SAE Aerospace Standard (AS) defines cleanliness levels for particulate contamination of hydraulic fluids and

includes methods of reporting data relating to the contamination levels. Tables 11.2 and 11.3 below provide the

Maximum Contamination Limits (Particles/100ml) of differential and cumulative particle counts respectively for

counts obtained by an automatic particle counter, e.g. CMS.

Table 11.2 AS4059E Table 1 Cleanliness Classes for Differential Particle Counts

Loading...

Loading...