5-4-11

INTAKE AND EXHAUST VALVE

(1)

Clean carbon and gum deposits from the valves, seats, ports and guides. Inspect valves, valve

(2)

Replace valves that are badly burned, pitted or warped.

(3)

When installing valves in cylinder head. Oil valve stems and insert them into valve guide.

Then place cylinder head on flat table, install washer, valve spring and spring retainer.

seats and valve guides..

(4)

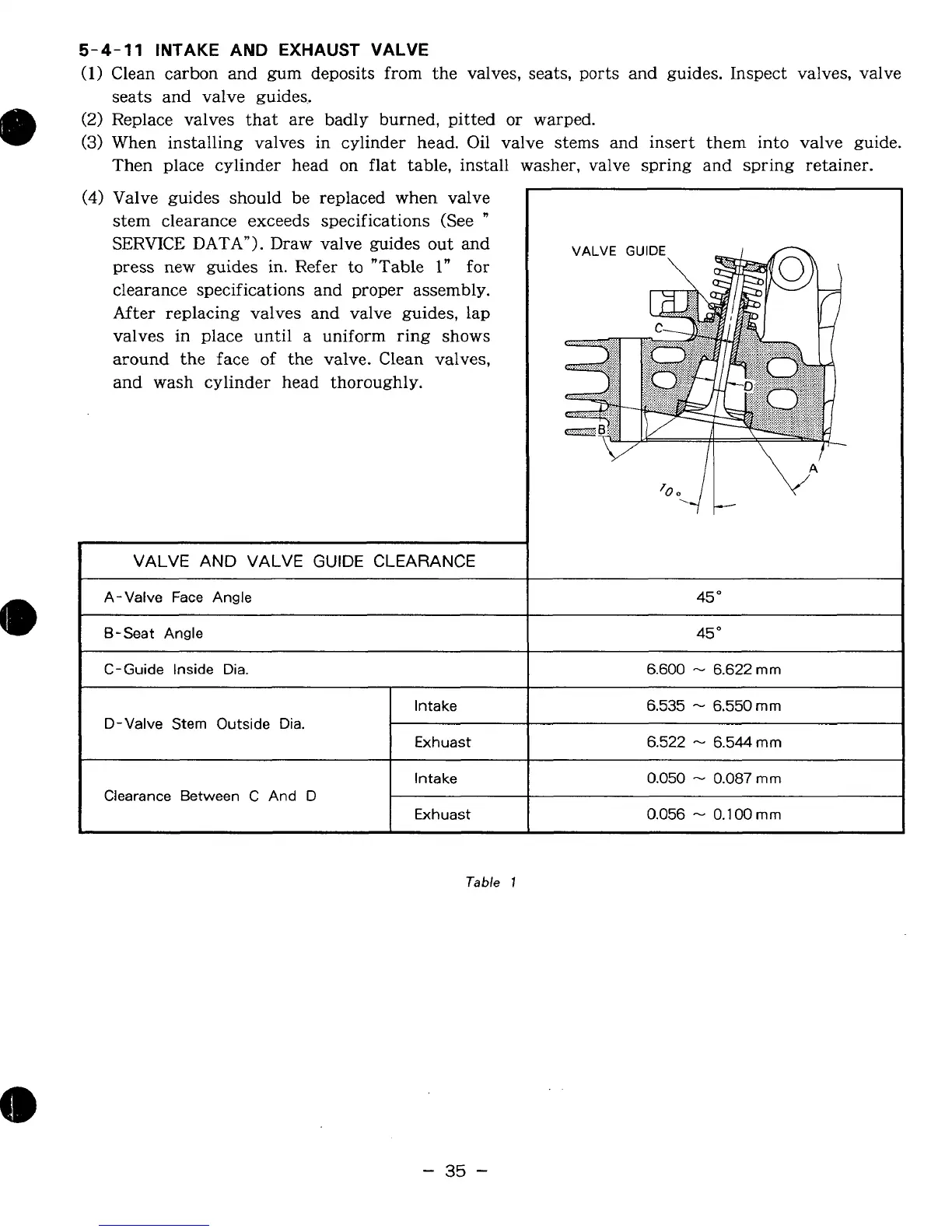

Valve guides should be replaced when valve

stem clearance exceeds specifications (See

"

SERVICE

DATA").

Draw valve guides out and

press

new

guides in. Refer to "Table

1"

for

clearance specifications and proper assembly.

After replacing valves and valve guides, lap

valves in place until a uniform ring shows

around the face

of

the valve. Clean valves,

and wash cylinder head thoroughly.

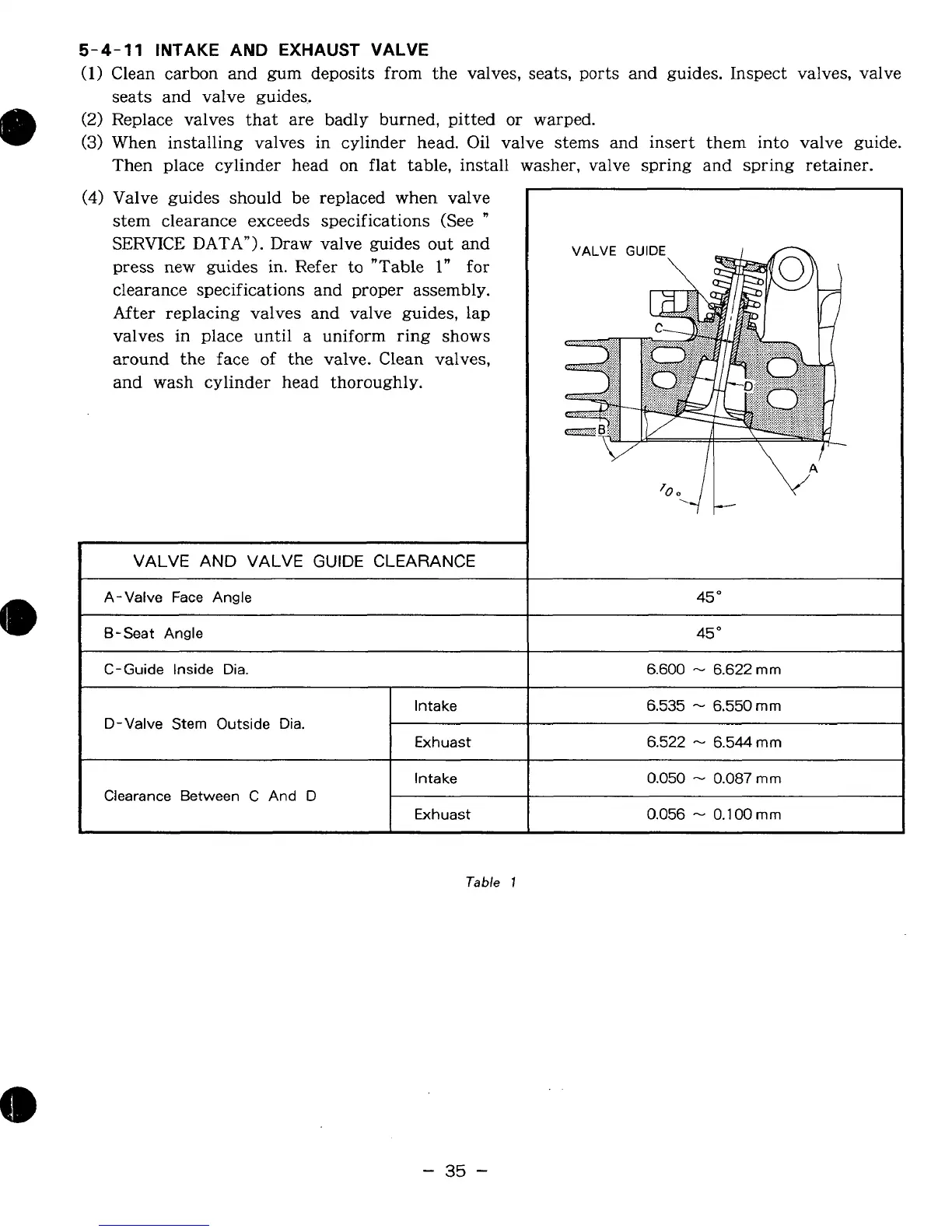

VALVE

AND

VALVE

GUIDE

CLEARANCE

A-Valve Face Angle

B-Seat Angle

C-Guide Inside Dia.

Intake

Exhuast

D-Valve Stem Outside Dia.

Clearance Between

C

And D

I

Intake

I

Exhuast

t

45

45

6.600

-

6.622

mm

6.535

-

6.550

mm

6.522

-

6.544 mm

0.050

-

0.087

mrn

0.056

-

0.100mrn

Table

7

-

35

-

Loading...

Loading...