14-3

CONFIRMATION ITEMS AFTER REASSEMBLY (Type

D)

1)

Pull

the starting knob

2

or

3

times, and pull out the starter rope

a

little.

i)

If

the starting knob is felt heavy to pull and cannot be pulled, check whether the parts were reassembled correctly

as instructed.

n)

If the ratchet does not function, check whether the spring is hooked properly.

2)

Pull the starting knob, and pull out the starter rope all the way long.

i)

If

the starter rope remains left in the reel or the starter rope does not return at all, immoderate strain is imposed on

the spring.

So

rewind the starter rope

1

or

2

times as per instruction in Fig.

68.

ii)

If the return power of the starter rope is weak

or

the starting knob is drooped

on

the way, inject

a

few drops

of

mobile

oil

in the frictional portions. If it does not revive yet, wind it

1

or

2

times.

(In

this case, refer to the instruc-

tions explained in the paragraph

i)

above and

confirm

whether or not immoderate strain is imposed

on

the spring.)

iii)

If the sound is heard that the spring is falling off, and the starter rope cannot.be wound in relay, reassemble once

again from the biginning.

14-4

HOW

TO

DO

IN

SUCH

CASES!

1)

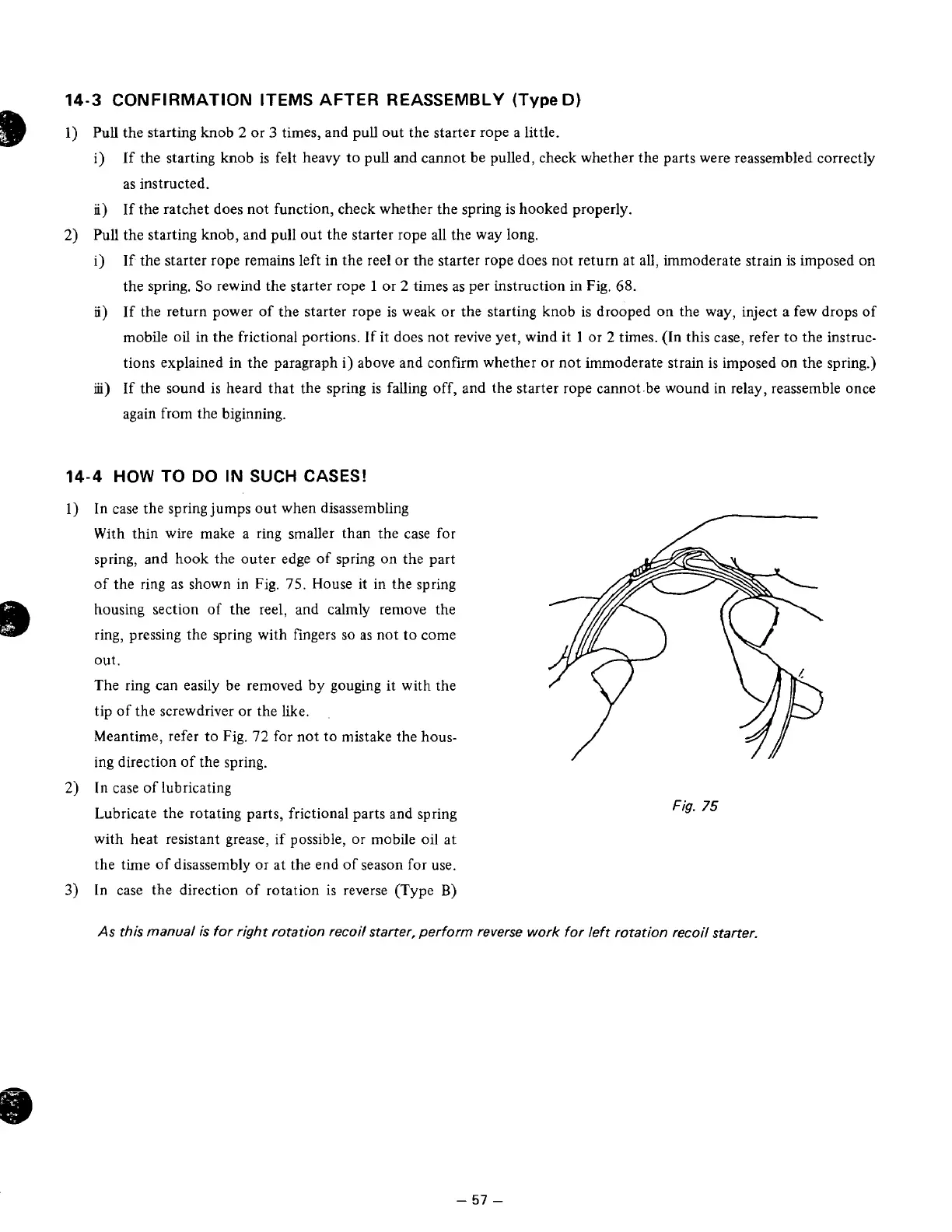

In case the spring jumps out when disassembling

With thin wire make a ring smaller than the case for

spring, and hook the outer edge of spring on the part

of the ring

as

shown

in

Fig. 75. House it in the spring

housing section of the reel, and calmly remove the

ring, pressing the spring with fingers

so

as not

to

come

out.

The ring can easily be removed by gouging it with the

tip of the screwdriver or the like.

Meantime, refer to Fig.

72

for

not

to mistake the hous-

ing direction of the spring.

2)

In

case of lubricating

Lubricate the rotating parts, frictional parts and spring

with heat resistant grease, if possible,

or

mobile oil at

the time of disassembly

or

at the end

of

season for use.

3)

In

case the direction of rotation

is

reverse (Type

B)

Fig.

75

As

this manual is

for

right rotation

recoil

starter, perform reverse

work

for

left rotation recoil starter.

-

57

-

Loading...

Loading...